A kind of pad dyeing method of dark polyester fabric

A polyester fabric and dyeing method technology, applied in the field of polyester fabric dyeing, can solve the problems that are not suitable for the continuous production and processing of thick and dark polyester fabrics, cannot meet the full absorption of disperse dyes, permeate and diffuse, and have poor hygroscopicity, and achieve color fastness Excellent, the effect of improving color fastness and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

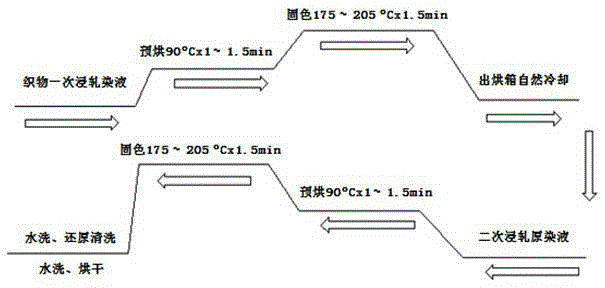

[0026] Embodiment 1 Dyeing of polyester decorative tape

[0027] Prepare the padding solution, weigh 10g / L of low-temperature dye disperse red, 2g / L of dispersant MF, 2g / L of penetrating agent JFC and 25g / L of 3% sodium alginate, put them into the padding tank, add water to the total amount of the padding solution , Stir evenly, immerse the polyester decorative tape into the dye solution in the rolling tank → pass through the rolling press → immerse in the dye solution → rolling (the rolling rate is 60%). Put the padding polyester decorative tape into the oven for pre-baking (90°C, 1min), enter the oven to fix the color (175°C, 1.5min), and leave the oven to cool; put the once-dyed polyester decorative tape into the padding groove again Dye liquor, pre-baking (90°C, 1min), baking and fixing reaction (175°C, 1.5min), out of the oven;

[0028] Wash the secondary dyed polyester decorative tape with water, reduce cleaning (sulfate 3g / L, caustic soda 3g / L, 80℃×3min), wash with wat...

Embodiment 2

[0030] Embodiment 2 polyester fabric dyeing

[0031] Prepare the padding solution, weigh 15g / L of low-temperature dye disperse yellow, 2g / L of dispersant MF, 2g / L of penetrating agent JFC and 30g / L of 3% sodium alginate, put them into the padding tank, add water to the total amount of the padding solution , Stir evenly, immerse the polyester fabric in the dye solution in the rolling tank → pass through the rolling press → immerse in the dye solution → rolling (the rolling rate is 45%). Put the padded polyester fabric into the oven for pre-drying (90°C, 1.5min), enter the oven to fix the color (180°C, 1.5min), and leave the oven to cool; put the polyester fabric once dyed into the padding tank again for padding and original dyeing Liquid, pre-baking (90°C, 1.5min), baking and fixing reaction (180°C, 1.5min), out of the oven;

[0032] Wash the secondary dyed polyester fabric with water, reduce cleaning (3g / L sodium hydrosulfite, 3g / L caustic soda, 80℃×3min), wash with water, an...

Embodiment 3

[0034] Example 3 Polyester binding tape dyeing

[0035] Prepare padding solution, weigh 15g / L of medium-temperature disperse blue dye, 2g / L of dispersant MF, 2g / L of penetrating agent JFC and 35g / L of 3% sodium alginate, put them into the padding tank, add water to the total amount of padding solution , Stir evenly, immerse the polyester strap into the dye solution in the rolling tank → pass through the rolling press → immerse in the dye solution → rolling (the rolling rate is 45%). Put the padding polyester strap into the oven for pre-baking (90°C, 1.5min), enter the oven for color fixation (190°C, 1.5min), and leave the oven to cool; put the dyed polyester strap into the padding tank again for padding The original dye solution, pre-baking (90°C, 1.5min), baking and fixing reaction (190°C, 1.5min), out of the oven;

[0036] Wash the secondary dyed polyester strapping with water, reduce cleaning (3g / L sodium hydrosulfite, 3g / L caustic soda, 80℃×3min), wash with water, and dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com