Colored polyester staple fiber with skin-core structure and preparation method thereof

A technology of colored polyester and skin-core structure, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, and conjugated synthetic polymer rayon. Time cost and other issues, to achieve uniform color, solve the effect of different shades of color, reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

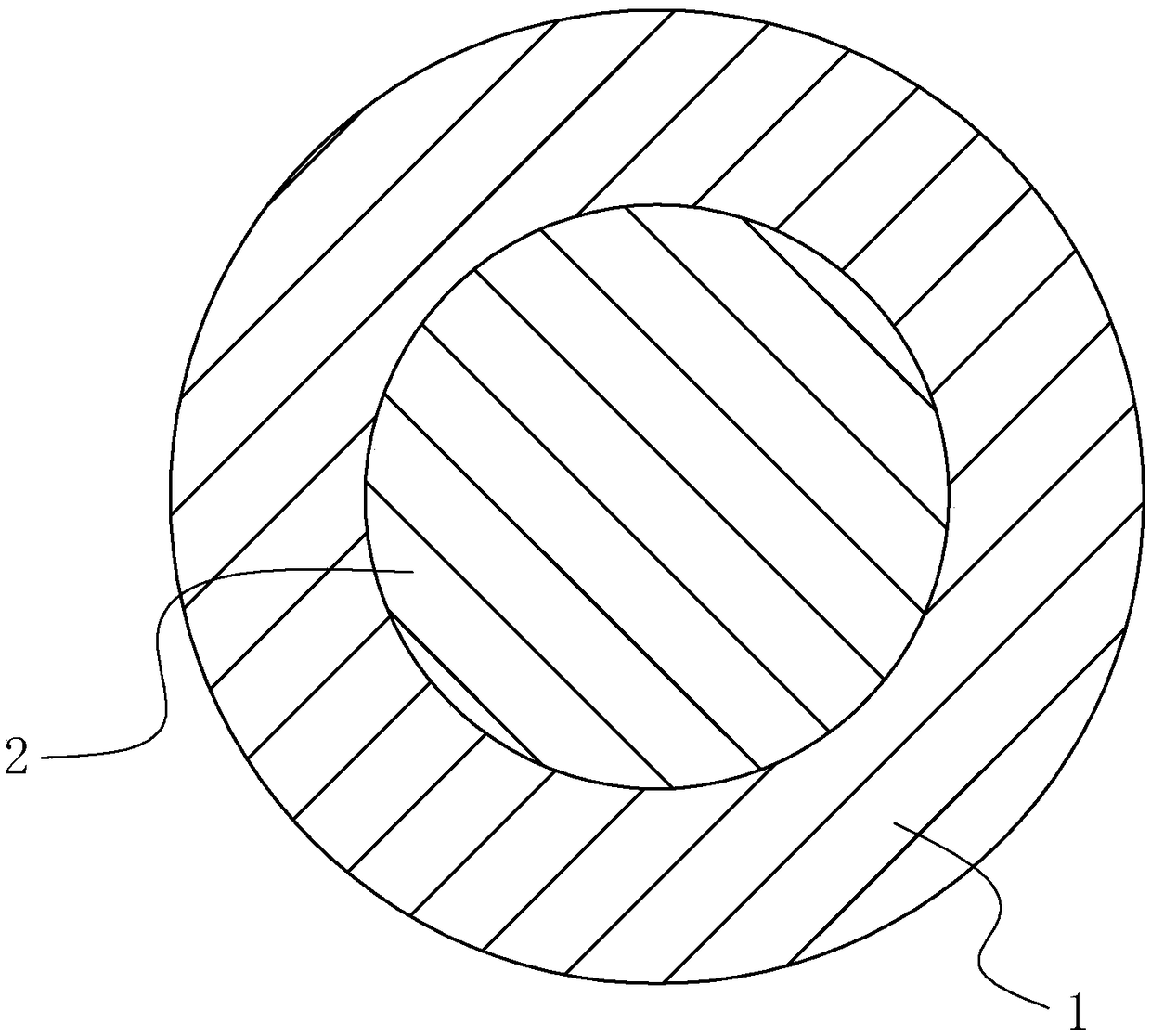

Image

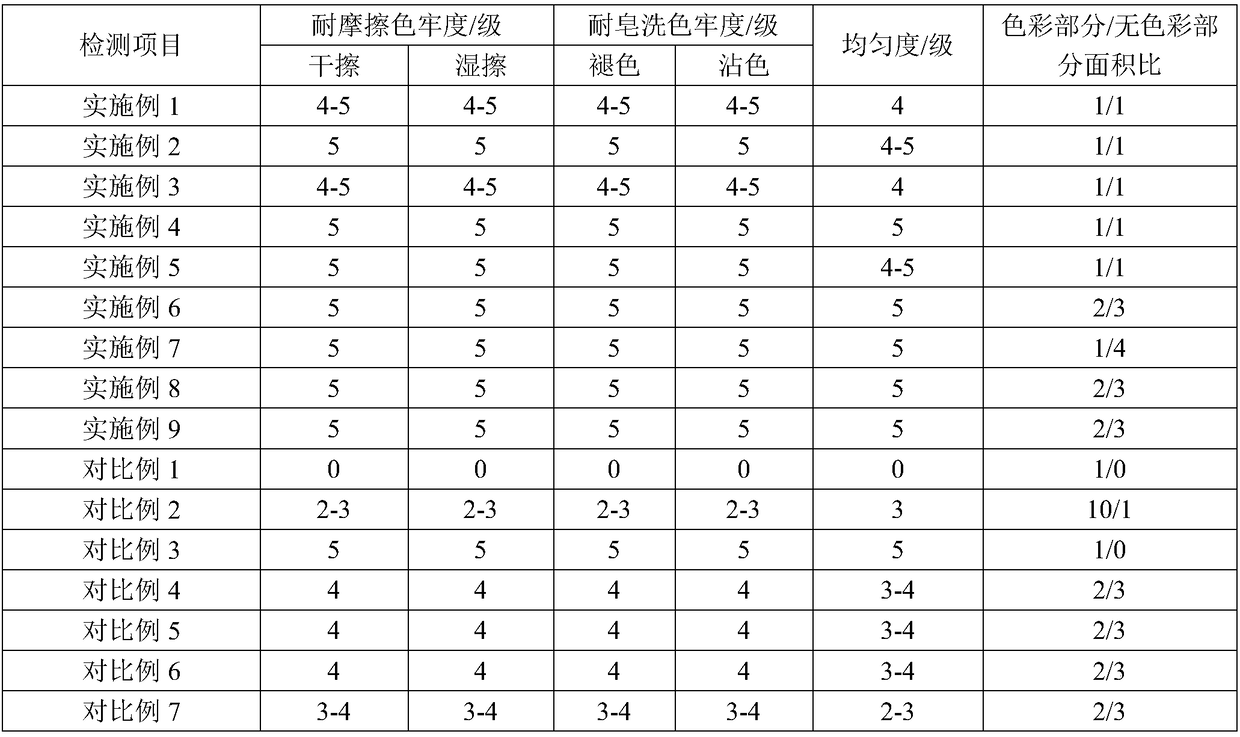

Examples

Embodiment 1

[0041] (1) APET and color masterbatches of the weight formula are taken, and mixed uniformly in a mixer to obtain a cortical mixture;

[0042] (2) Put APET into the compound spinning box after passing through the metering pump; at the same time, pass the uniformly mixed cortex mixture into the compound spinning box through the metering pump, and then pass through the skin-core composite spinning assembly, and spin at a temperature of 240°C Silk, and after cooling, oiling, drawing, deep drawing, and shaping, colored polyester fibers are obtained;

[0043] (3) Finally, the colored polyester fiber is cut into staple fibers of required specifications to obtain colored polyester staple fibers with a sheath-core structure.

[0044] Among them, the color masterbatch is prepared by the following method: Weigh each component of the weight formula, put polypropylene resin, polyethylene wax, fatty alcohol polyoxyethylene ether in a high-speed mixer and stir for 10 minutes, and then add b...

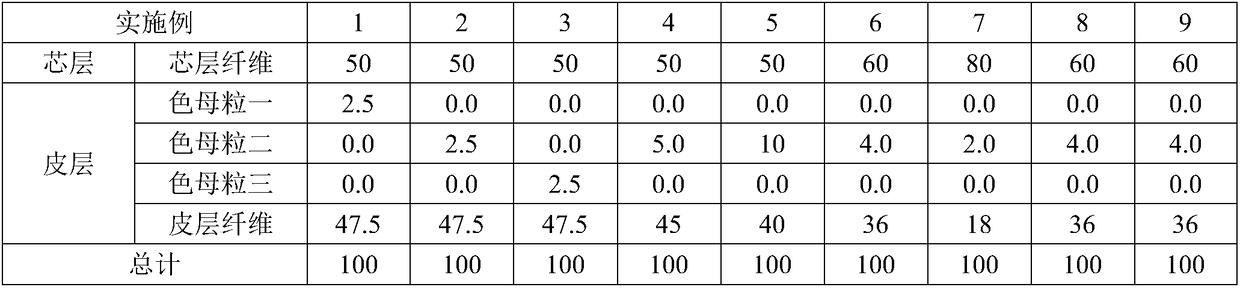

Embodiment 2-7

[0046] The difference between Examples 2-7 and Example 1 is that the ratio of raw materials for preparing the colored polyester staple fiber with a sheath-core structure is different, as shown in Table 1 and Table 2.

Embodiment 8

[0048] The difference between embodiment 8 and embodiment 6 is that the process conditions and some raw materials for preparing the colored polyester staple fiber of sheath-core structure are different;

[0049] (1) RPET and color masterbatches of the weight formula are taken, and mixed uniformly in a mixer to obtain a cortical mixture;

[0050] (2) Put PETG through the metering pump and then enter the composite spinning box; at the same time, pass the uniformly mixed cortex mixture into the composite spinning box through the metering pump, and then pass through the skin-core composite spinning assembly, and spin at a temperature of 260°C Silk, and after cooling, oiling, drawing, deep drawing, and shaping, colored polyester fibers are obtained;

[0051] (3) Finally, the colored polyester fiber is cut into staple fibers of required specifications to obtain colored polyester staple fibers with a sheath-core structure.

[0052] Among them, the color masterbatch is prepared by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com