Dye-fixing agent for bright cloth, a preparation method of dye-fixing agent and method for preparing bright cloth

A color-fixing agent and fabric sample technology, which is applied in the textile and printing and dyeing fields, can solve the problems of low color fastness to bright cloth and low light fastness, and achieve the effect of improving the color fastness to rubbing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

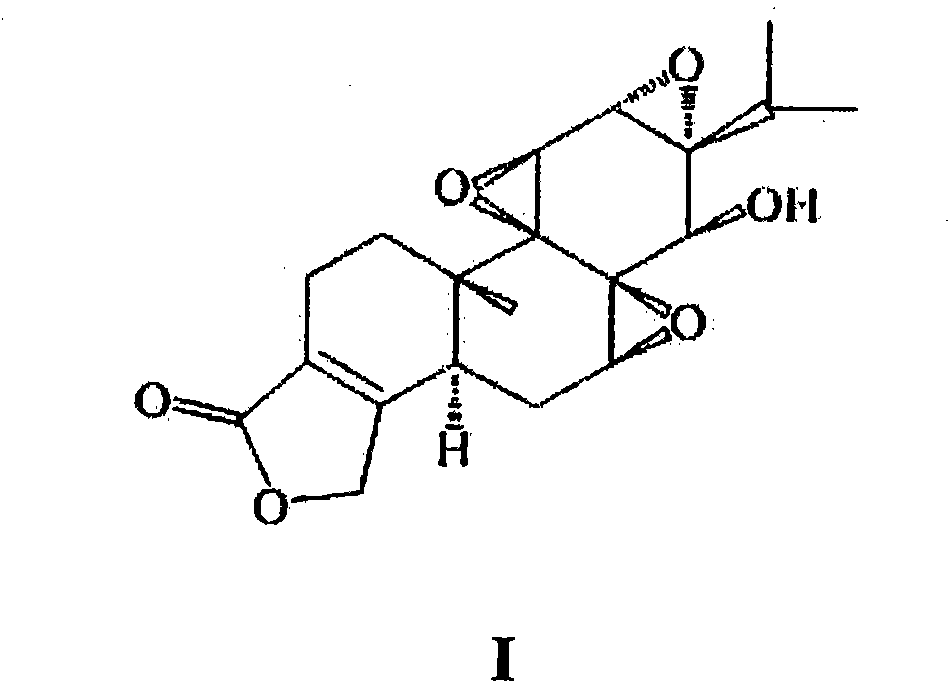

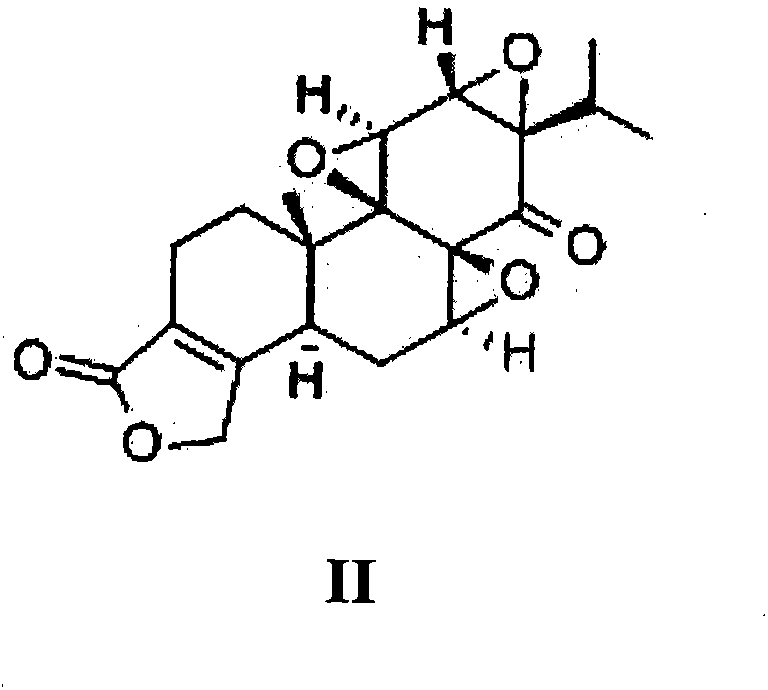

[0092] Preparation Example 1: Preparation of Color Fixing Agent 1 for Bright Cloth

[0093] 1. Reagents

[0094] Color-fixing agent raw material comprises the component of following parts by weight:

[0095] Triptolide: 3, triptolide ketone: 2, dulcitol: 4, ranangyrolactone: 10, valerian triester: 10, soybean polypeptide: 6, 1,4-diguanidinobutane: 6. Water: 80.

[0096] 2. Preparation process

[0097] Add 10 parts by weight of nanbutyrolactone, 10 parts by weight of valerian triglycerides, and 80 parts by weight of water into the reactor, adjust the temperature of the mixture to 25°C while stirring, and slowly add Tripterygium wilfordii through a constant-pressure dropping funnel 3 parts by weight of ketone, 2 parts by weight of triptolide ketone, 4 parts by weight of dulcitol, the temperature in the reactor is controlled at 30°C, and the temperature in the reactor is maintained at 30°C. , 6 parts by weight of 4-diguanidinobutane, control the reaction temperature at 30°C...

preparation example 2

[0099] Preparation Example 2: Preparation of Color Fixing Agent 2 for Bright Cloth

[0100] 1. Reagents

[0101]The color-fixing agent raw material includes the following components by weight: triptolide: 5, triptolide ketone: 4, dulcitol: 6, runangyrolactone: 20, valerian triester: 20, soybean polypeptide: 14, 1,4-diguanidinobutane: 14, water: 120.

[0102] 2. Preparation process

[0103] Add 20 parts by weight of nanbutyrolactone, 20 parts by weight of valerian triglycerides, and 120 parts by weight of water into the reactor, adjust the temperature of the mixture to 30°C while stirring, and slowly add Tripterygium wilfordii through a constant-pressure dropping funnel 5 parts by weight of ketone, 4 parts by weight of triptolide ketone, and 6 parts by weight of dulcitol. The temperature in the reactor is kept at 30°C by controlling the rate of addition. After the addition, 14 parts by weight of soybean polypeptide, 1 , 14 parts by weight of 4-diguanidinobutane, control th...

preparation example 3

[0105] Preparation Example 3: Preparation of Fixing Agent 3 for Bright Cloth

[0106] 1. Reagents

[0107] The color-fixing agent raw material includes the following components by weight: triptolide: 4, triptolide ketone: 3, dulcitol: 5, runangyrolactone: 15, valerian triester: 15, soybean polypeptide: 10, 1,4-diguanidinobutane: 10, water: 100.

[0108] 2. Preparation process

[0109] Add 15 parts by weight of nanbutyrolactone, 15 parts by weight of valerian triglycerides, and 100 parts by weight of water into the reactor, adjust the temperature to 30°C while stirring, and slowly add triptolide 4 by using a constant pressure dropping funnel. Parts by weight, 3 parts by weight of triptolide ketone, 5 parts by weight of dulcitol, control the rate of addition to keep the temperature in the reactor at 30°C, keep the reaction for 1h after the addition, and then add 10 parts by weight of soybean polypeptide, 1,4 - 10 parts by weight of diguanidinobutane, control the reaction te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com