Direct/disperse one-bath method short-process dyeing and finishing technology for polyester-cotton knitted fabric

A knitted fabric and short-process technology, which is applied in the field of textile dyeing and finishing, can solve the problems of long time consumption, many processing machines, and high energy consumption, and achieve the goals of improving color fastness to rubbing, good UV resistance, and reducing process steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

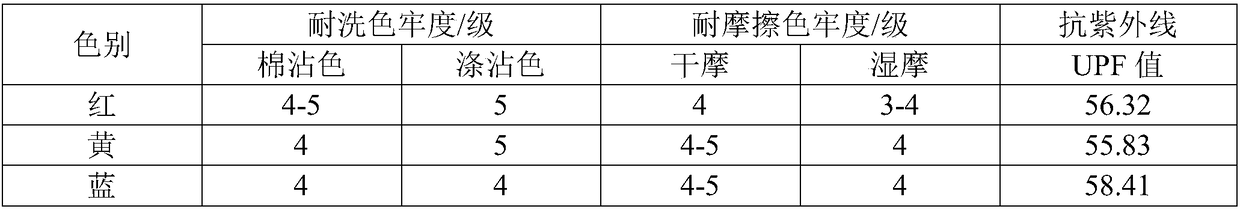

Examples

Embodiment 1

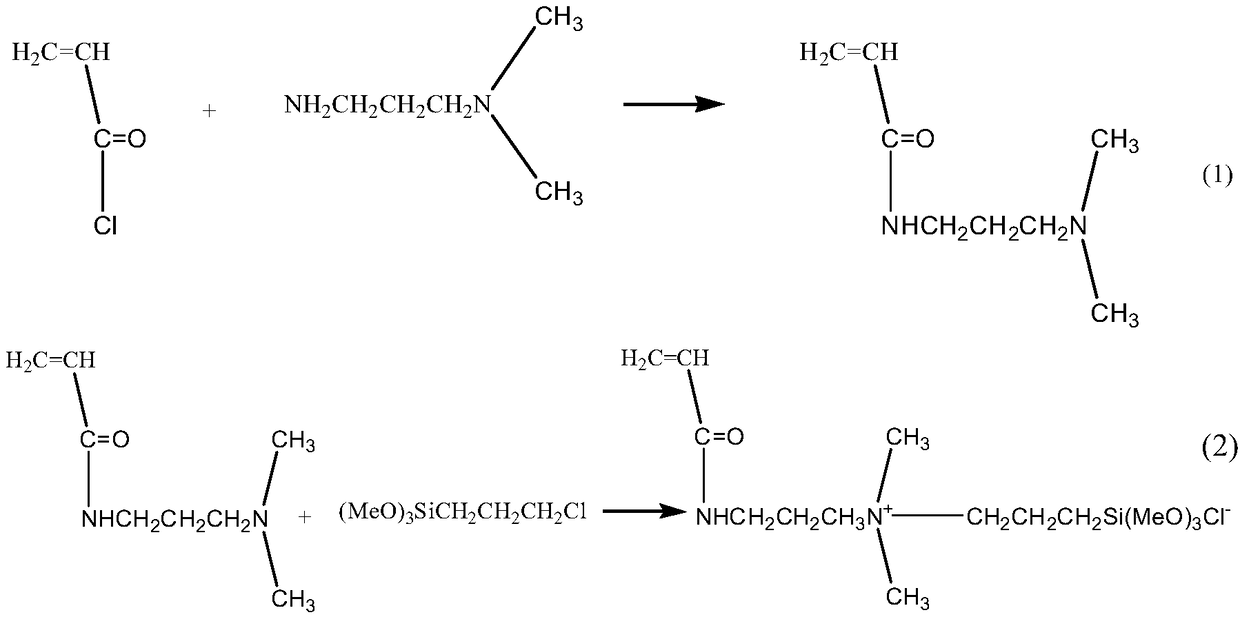

[0035] Preparation of 3-acrylamidopropyldimethylpropyltrimethoxysilane ammonium chloride

[0036] It is made of N,N dimethylpropylenediamine, acryloyl chloride, and γ-chloropropyltrimethoxysilane. The specific preparation method is:

[0037] Add 82mL of dichloromethane, 25mL of 6mol / L sodium hydroxide, 0.1molN,N dimethylpropylenediamine into a 250mL three-necked flask, N2 protection, ice-water bath, under N2 protection, magnetically stir evenly. Slowly add 25 mL of dichloromethane solution dissolved with 0.104 mol of acryloyl chloride with a constant pressure funnel, keeping the reaction temperature not exceeding 5°C. After the dropwise addition was completed, the stirring was continued for 30 min. Several layers were taken out and washed twice with water and twice with saturated sodium chloride solution, then dried with anhydrous sodium sulfate, and then evaporated to remove the solvent with a rotary evaporator to obtain a light yellow oil, which was then distilled under red...

Embodiment 2

[0040] Direct / dispersion one-bath short-process dyeing and finishing process of polyester-cotton knitted fabrics, including one-bath pretreatment, dyeing, soaping, and finishing.

[0041] (1), one-bath pretreatment

[0042] The polyester-cotton knitting is arranged in the machine cylinder, the bath ratio is 1:8, add sodium hydroxide 10g / L, 30% hydrogen peroxide 15g / L, sodium silicate 2g / L, sodium lauryl sulfate 2g / L, secondary alkyl Sodium sulfonate 3g / L, AEO-9 3g / L, treat at 95-100°C for 45min, then cool down to 40°C, neutralize to neutral with glacial acetic acid, drain the waste liquid, and wash with water;

[0043] (2), dyeing

[0044] Prepare the dye solution with a bath ratio of 1:8, disperse dye 1-5% owf, high-temperature leveling agent 2g / L, adjust the pH value to 5.5-6 with acetic acid, raise the temperature at 1.5°C / min to 130°C, and keep it warm for 45 minutes; ℃ / min to cool down to 65°C, add direct blended dye 1-5% owf, sodium sulfate 20-30g / L, heat up to 95°C at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com