Method of dyeing and finishing cationic polyester fabrics

A cationic polyester and cationic dye technology, applied in dyeing method, textile material processing, continuous processing of textile materials, etc., can solve the problems of easy fading and color defects of cationic polyester fabrics, improve color fastness and save time , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

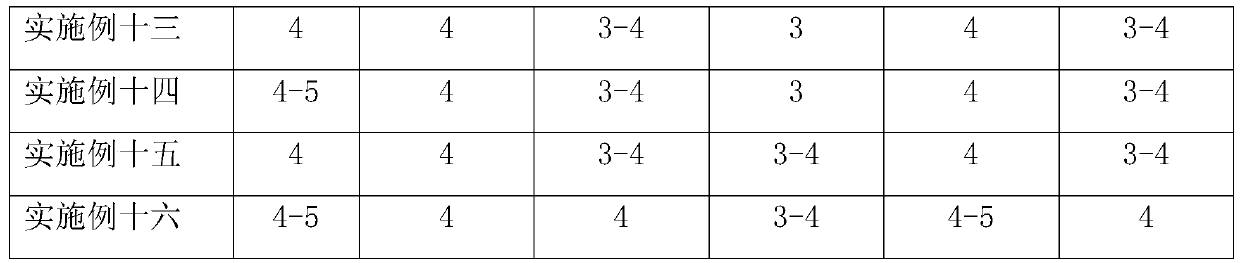

Examples

Embodiment 1

[0086] Embodiment one: a kind of cationic polyester fabric dyeing and finishing method, concrete operation is as follows:

[0087] Step 1: Desizing, use the OS open-width desizing machine to desizing the cationic polyester fabric: first, the cationic polyester fabric is desizing with a 30% sodium hydroxide solution and the solution temperature is 60°C, and then washed in warm water Desizing solution, and finally dry the cationic polyester fabric;

[0088]Step 2: Alkali reduction, use a loose alkali measuring machine to carry out alkali reduction operation on cationic polyester fabrics: first, the cationic polyester fabrics are desized with a 5% sodium hydroxide solution and the solution temperature is 90°C, and then put into warm water Clean the desizing solution, and finally dry the cationic polyester fabric;

[0089] Step 3: Dye preparation: (printing and dyeing colors can be formulated according to the combination of disperse dyes and cationic dyes: cationic red SD-GRL and...

Embodiment 2

[0099] The difference between embodiment two and embodiment one is:

[0100] Step 3: Dye preparation: dye components include disperse blue 2BLN1.0% owf, cationic yellow SD-5GL1.0% owf, glacial acetic acid 1g / L, polyester superfine fiber high temperature leveling agent TF-212K 1.2g / L, Ammonium sulfate 0.5g / L;

[0101] Step 3.1: Add glacial acetic acid 1g / L to the chemical material, disperse dye 1.0% owf and cationic yellow SD-5GL 1.0% owf, stir to form a slurry, add polyester superfine fiber high temperature leveling agent TF-212K 1.2g / L , ammonium sulfate 0.5g / L, and adjust the pH to 5, according to the bath ratio of 1:40;

[0102] Step 3.2: beat the material, the temperature rises to 80°C, stir and beat the material;

Embodiment 3

[0104] The difference between embodiment three and embodiment one is:

[0105] Step 3: Dye preparation: dye components include disperse blue 2BLN3.0% owf, cationic yellow SD-5GL3.0% owf, glacial acetic acid 1g / L, polyester superfine fiber high temperature leveling agent TF-212K 1.2g / L, Ammonium sulfate 0.5g / L;

[0106] Step 3.1: Add glacial acetic acid 1g / L to chemical materials, disperse dye 3.0% owf and cationic yellow SD-5GL 3.0% owf, stir to form a slurry, add leveling agent 1.2g / L, ammonium sulfate 0.5g / L, And adjust the pH to 5, according to the bath ratio of 1:40;

[0107] Step 3.2: beat the material, the temperature rises to 80°C, stir and beat the material;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com