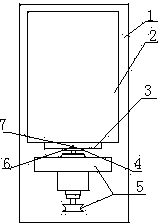

Inner drum-detachable pulsator washing machine

A pulsator washing machine and inner tub technology, applied in the field of washing machines, can solve the problems of dirt and bacteria retention and derivation, secondary pollution of laundry, peculiar smell, etc., and achieve the effect of non-polluting laundry environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

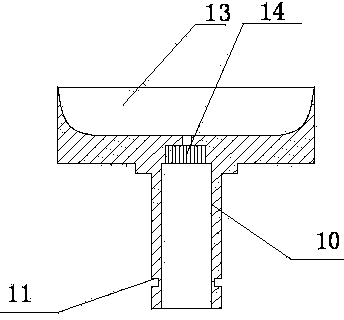

[0024] Embodiment 2: The bottom of the inner tub is provided with a spline groove, and the transmission mechanism 5 is provided with a spline matching the spline groove of the inner tub.

Embodiment 3

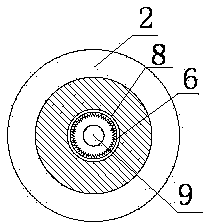

[0025] Embodiment 3: the transmission shaft 15 of the transmission mechanism 5 is a polygonal shaft, such as a square shaft or a triangular shaft, and the magnetizer 8 of the flange at the bottom of the outer wall of the inner barrel 2 is provided with a square groove that cooperates with the square shaft. The groove connection constitutes the axial positioning device. The transmission shaft 15 is a triangular shaft, and the magnetizer 8 of the outer wall bottom flange of the inner barrel 2 is provided with a triangular groove cooperating with the triangular shaft, and the triangular shaft is connected with the triangular groove to form an axial positioning device.

Embodiment 4

[0026] Embodiment 4: The washing machine is not provided with the electromagnet 4 and the magnetizer 8, and the inner tub 2 and the outer tub are mechanically driven mutually, such as a spline and a square shaft, and a bolt is used to screw the transmission mechanism 5 at the center of the pulsator, so that the inner tub and the pulsator The wheel will not float, and when cleaning is required, the center bolt of the wave wheel is removed, and the inner barrel 2 can be taken off.

[0027] Working principle of the present invention:

[0028] When working, the electromagnet 4 is energized to generate magnetism, and the inner barrel 2 is adsorbed on the transmission mechanism 5. The mutual mechanical transmission and center positioning of the electromagnet 4 and the magnetizer 8 (inner barrel 1 and the transmission mechanism) are also matched accordingly, and the washing machine is used for washing, During rinsing, the inner barrel 2 and the transmission mechanism 5 operate synchr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap