Different-thickness-magnetic-pole-containing surface-pasting type permanent magnet motor magnetic field computing method

A permanent magnet motor, magnetic field calculation technology, applied in the fields of calculation, electrical digital data processing, special data processing applications, etc., can solve the problems of complex motor structure, no longer uniform radial thickness, lack of magnetic field analytical calculation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

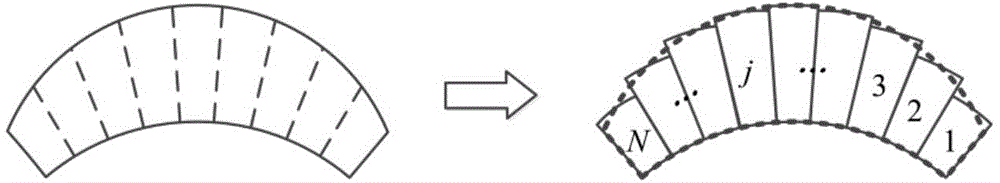

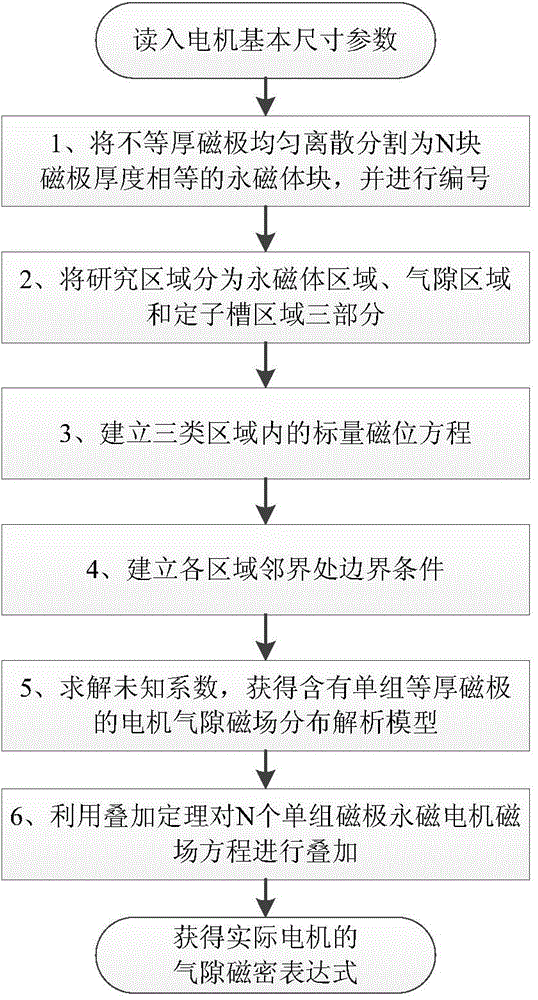

[0048] 101: Discretely divide the magnetic poles of unequal thickness along the circumferential direction, equivalent to N uniform and discrete permanent magnet blocks, and number the permanent magnet blocks under each pole;

[0049] like figure 1 As shown, this step adopts the idea of discrete, discretely divides the non-uniform thick magnetic poles along the circumferential direction, and converts them into N uniform and discrete permanent magnet blocks. The permanent magnet blocks under each pole are numbered j=1, 2, 3, . When N takes a larger value, it can be considered that the radial thickness of each permanent magnet block is approximately equal, so as to carry out mathematical modeling on the motor model of a single set of equal-thickness magnetic poles.

[0050] If the pole arc coefficient of the motor is α p , then the polar arc coefficient α of each permanent magnet block after uniform discretization pj for

[0051] alpha pj = α p / N (1)

[0052] Since the...

Embodiment 2

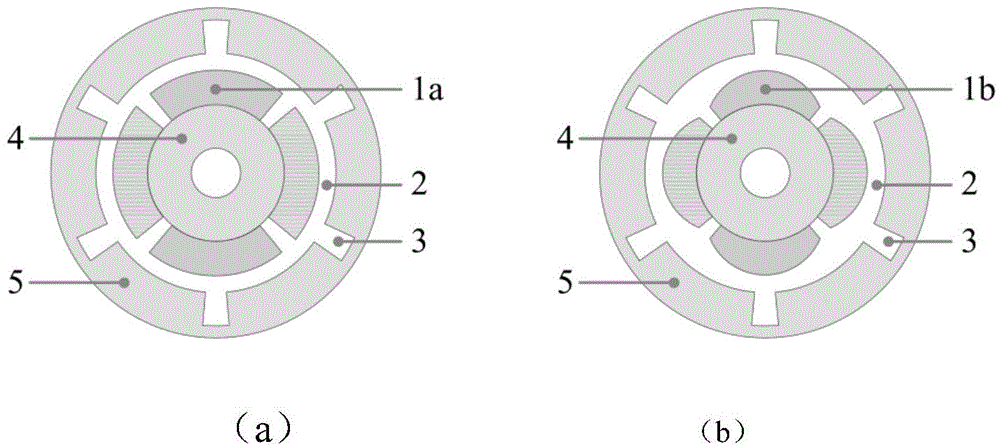

[0089] figure 2 It is a structural schematic diagram of a surface-mounted permanent magnet motor with conventional equal-thickness poles and a surface-mounted permanent magnet motor with eccentric poles. Among them, 1a is the traditional equal-thickness magnetic pole, 1b is the eccentric magnetic pole, 2 is the air gap, 3 is the stator slot, 4 is the rotor core, and 5 is the stator core. Compared figure 2 (a) and figure 2 (b) It can be found that the radial thickness of the traditional equal-thickness magnetic pole 1a is uniform and does not change with the change of the mechanical angular position; while the radial thickness of the eccentric magnetic pole 1b is uneven, thicker in the middle and thinner at both ends. Research shows that this kind of eccentricity The magnetic pole structure can effectively improve the magnetic field distribution in the air gap of the motor, and greatly reduce the back EMF harmonics and torque fluctuations, so it is widely used in surface-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com