Disengaging preventing solder strip fastening mechanism

A fastening mechanism and anti-falling technology, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of the fastening mechanism of the welding strip, single function, complex structure, etc., and achieve easy processing , Reduce manufacturing and maintenance costs, and the effect of simple and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

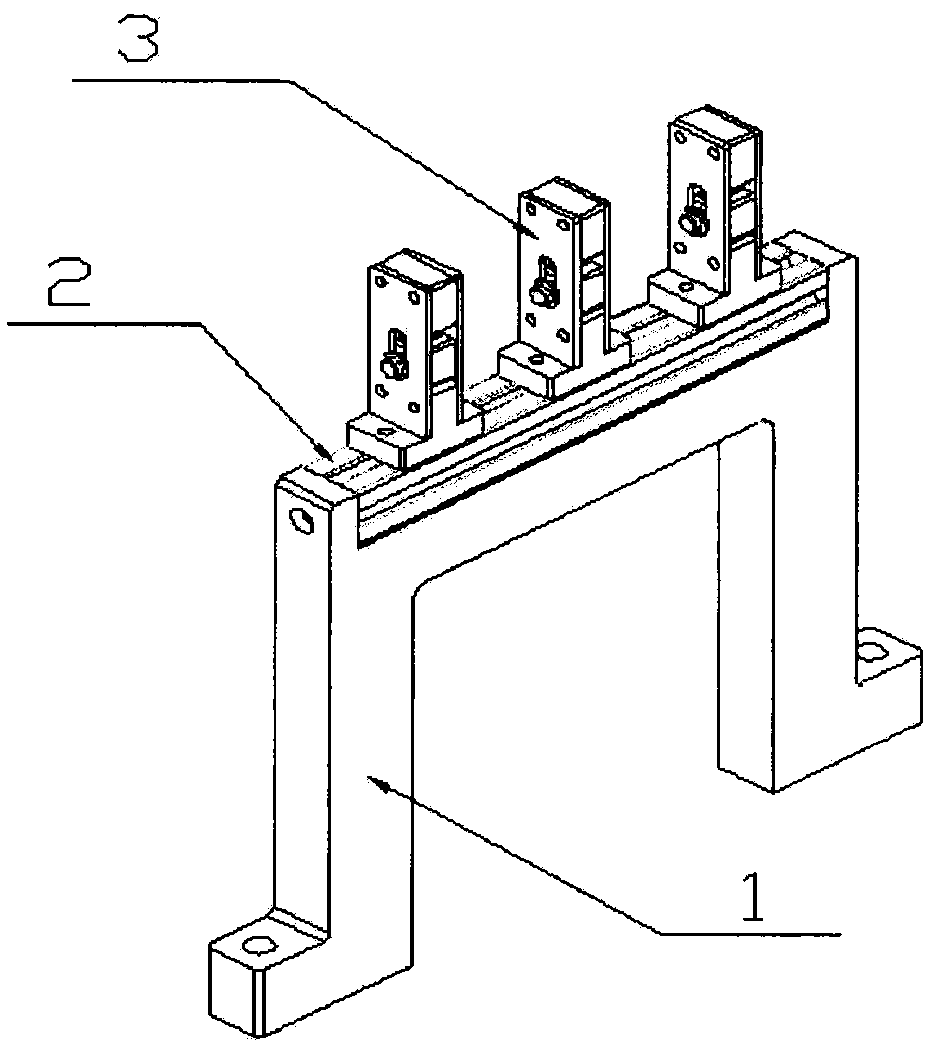

[0014] figure 1 It is a schematic diagram of the structure of the device of the present invention, including a bracket (1), a guide rod (2) and a fastening module (3); the guide rod (2) is embedded in the upper part of the bracket (1) in the horizontal direction, and is fixed by screws on both sides of the upper end. The solid module (3) is fixed above the guide rod (2).

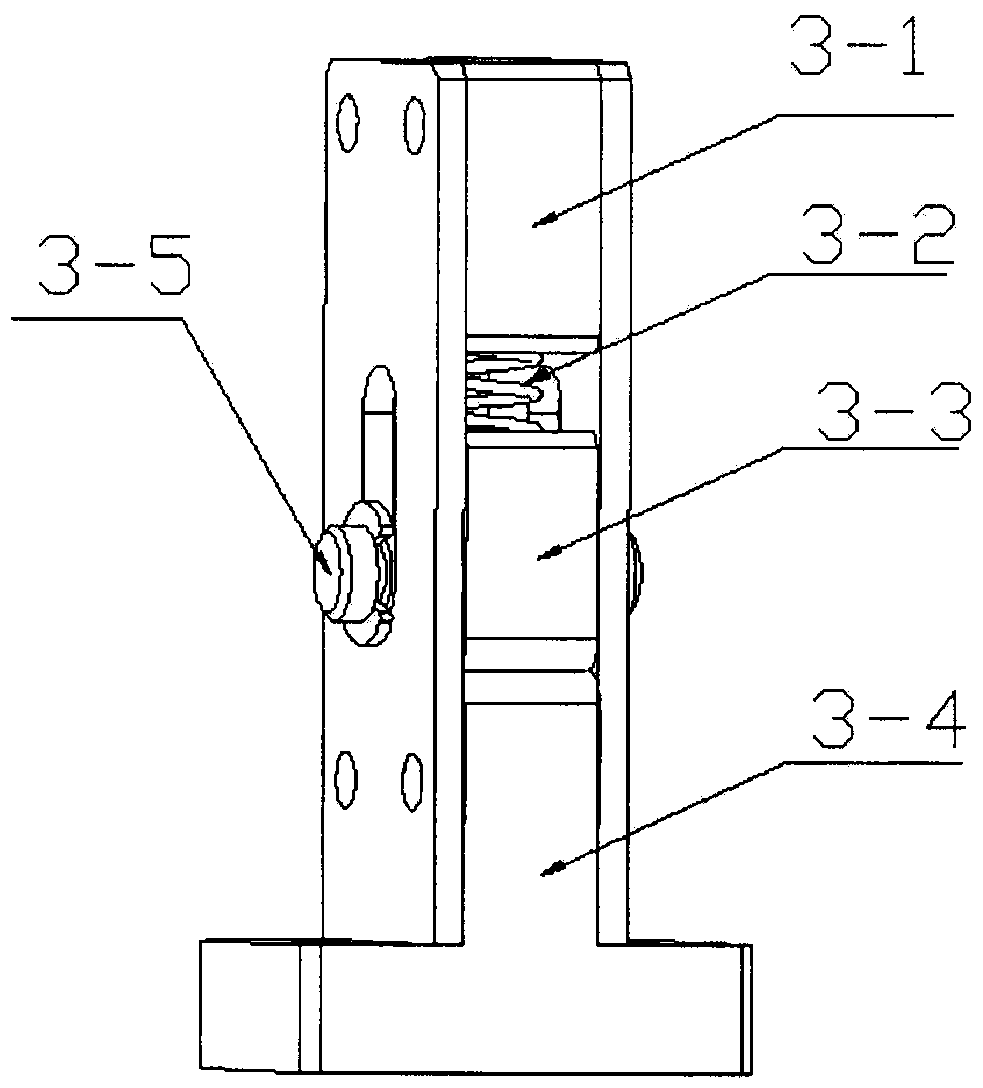

[0015] figure 2 It is a schematic diagram of the compression module of the device of the present invention, including an upper fixed block (3-1), a base (3-4), a spring (3-2), a pressing block (3-3) and a round shaft (3-5); The block (3-3) is vertically connected to the upper fixed block (3-1) through the spring (3-2), and is pressed against the base (3-4) by elastic force, and the circular shaft (3-5) passes through it horizontally Briquetting (3-3).

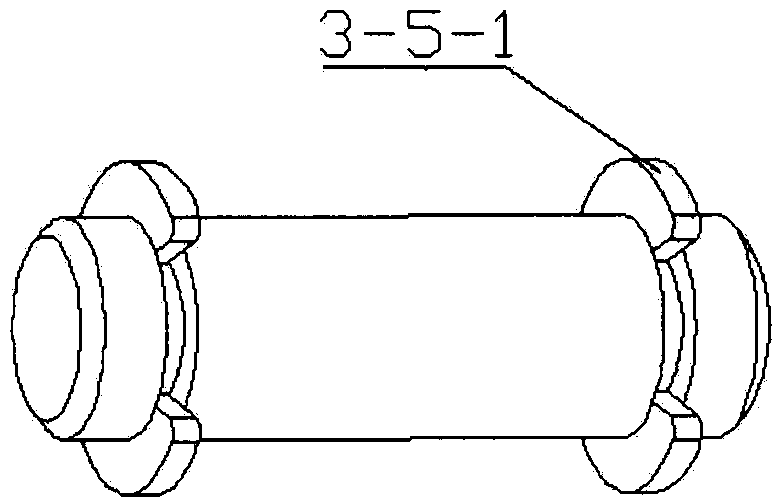

[0016] image 3 It is a schematic diagram of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com