Elastic press mechanism applied to photovoltaic batteries soldered in series

An elastic compression, photovoltaic cell technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of not being able to process cells of different specifications at the same time, and achieve the goal of being conducive to production popularization, clear structure, The effect of less equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

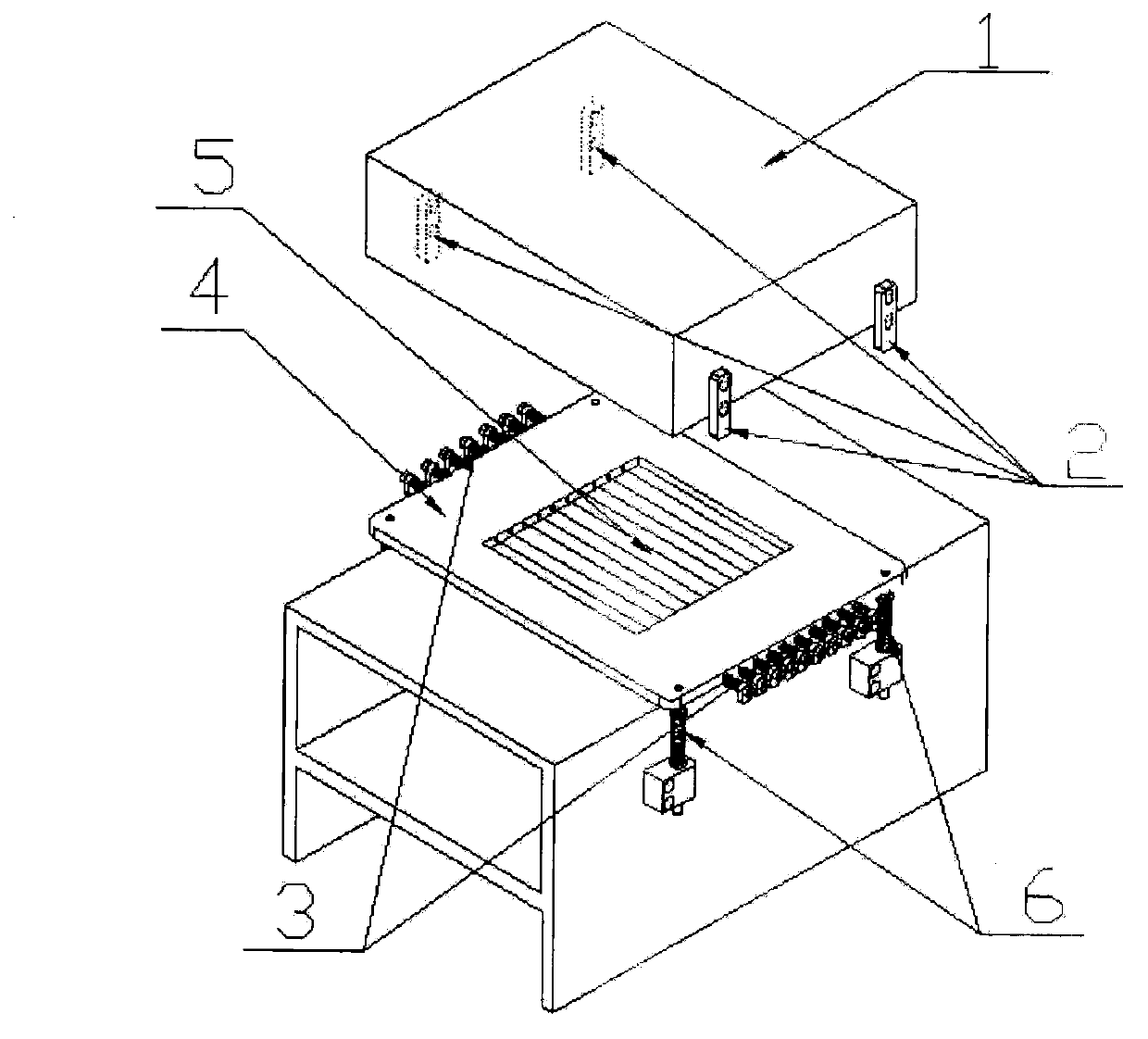

[0014] figure 1 It is a structural schematic diagram of the device of the present invention, including a pressing device (1), a pressing block (2), a locking spring (3), an elastic pressing mechanism (4), a metal wire (5) and a spring support frame (6); The pressing device (1) presses down, and the four pressing blocks (2) press down against the elastic pressing mechanism (4) until the metal wire (5) on the elastic pressing mechanism (4) presses the battery sheet; the welding is completed Finally, the pressing device (1) rises, and the elastic pressing mechanism (4) lifts automatically by the elastic force of the spring support frame (6).

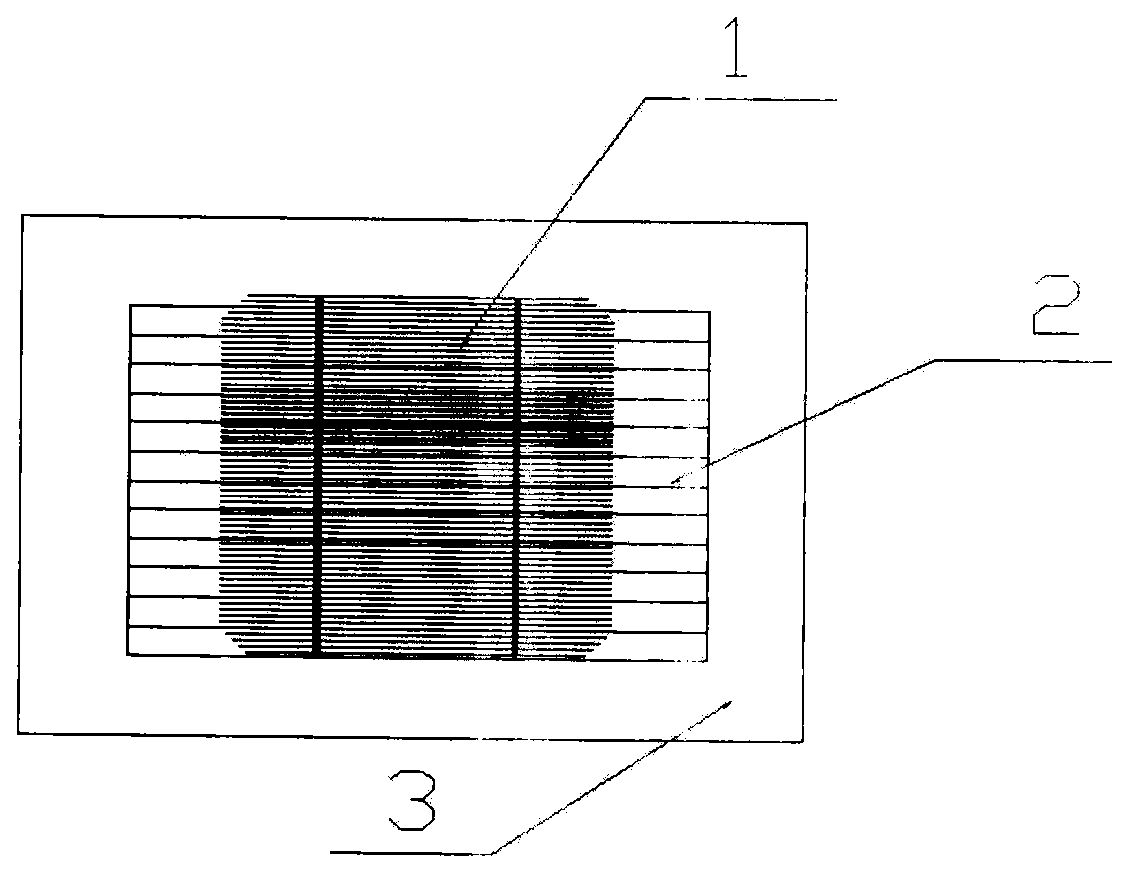

[0015] figure 2 It is a schematic diagram of pressing the battery sheet by the device of the present invention. When the elastic pressing mechanism is pressed down, the metal wire (2) presses the battery sheet (1) welding strip, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com