A grasping mechanism for curved photovoltaic crystalline silicon cells

A technology of crystalline silicon battery and grasping mechanism, which is applied in the direction of photovoltaic power generation, circuits, electrical components, etc., can solve the problems of low cost advantage and low production threshold, achieve simple processing, reduce manufacturing and maintenance costs, and high-speed grasping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the drawings:

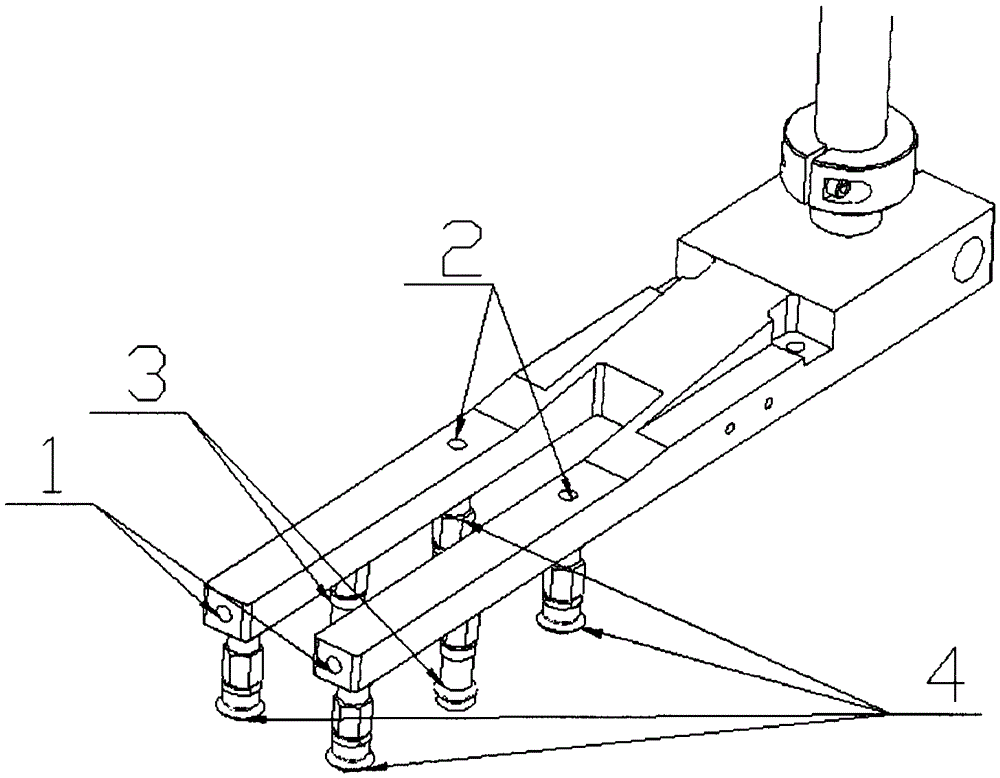

[0011] figure 1 It is a schematic diagram of the structure of the device of the present invention. A gripping mechanism for bending photovoltaic crystalline silicon cells includes a swing arm and a suction cup group; the head of the swing arm is U-shaped, the middle is a rising slope, and the rear is a square block; the swing arm There are two threaded air holes (1) in the middle of the U-shaped head, and two air holes (2) at the back of the upper part; the suction cup group includes four flat-head suction cups (4) and two corrugated suction cups (3), distributed The method is three on each side of the front of the swing arm, with the flat suction cup on the outside and the corrugated suction cup in the middle, and the arrangement is horizontal alignment and vertical alignment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com