Grounding pile

A technology of grounding piles and grounding pins, which is applied in the field of electric power engineering, can solve the problems of power line maintenance and inconvenient use, and achieve the effects of high reliability, extended service life and effective life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

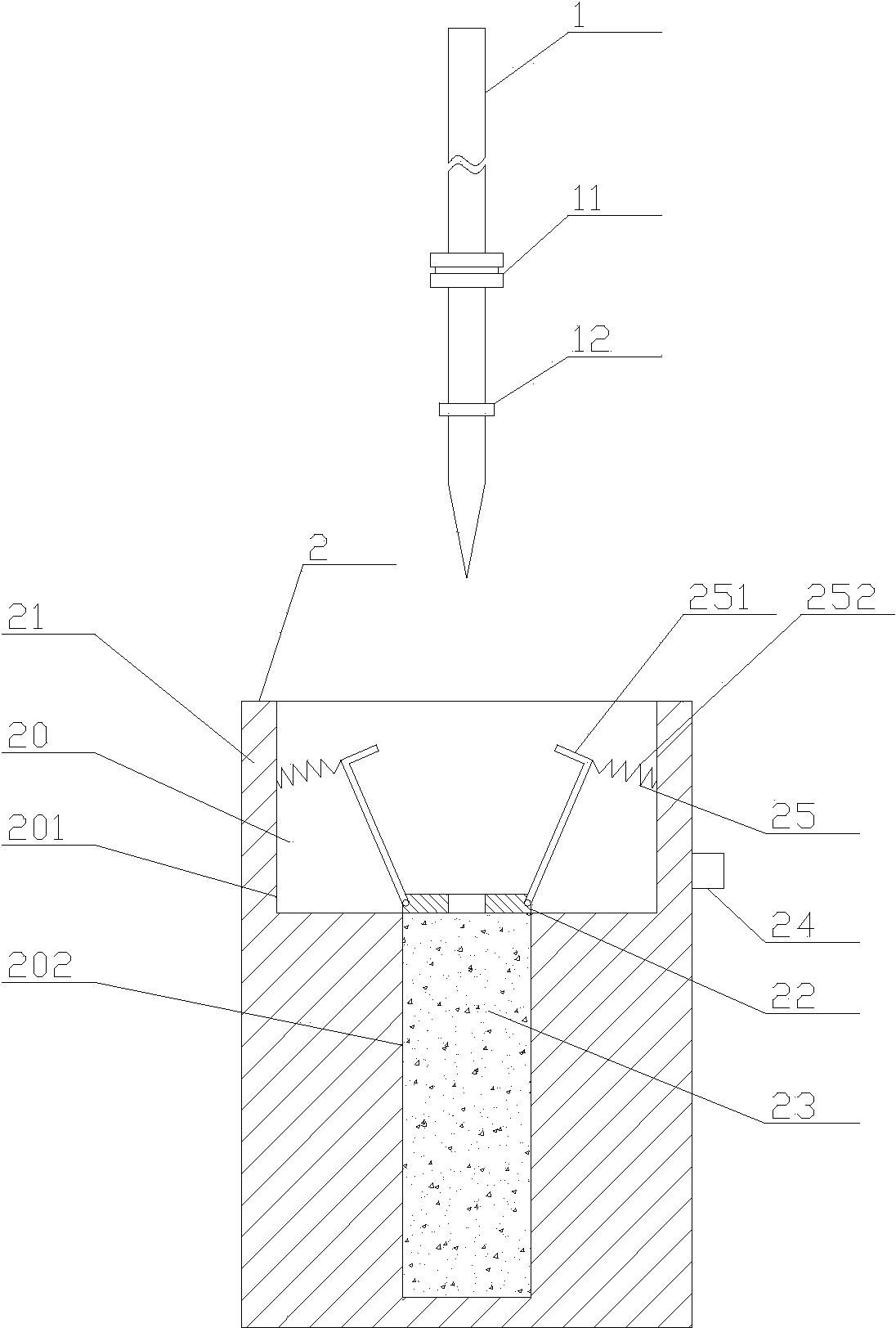

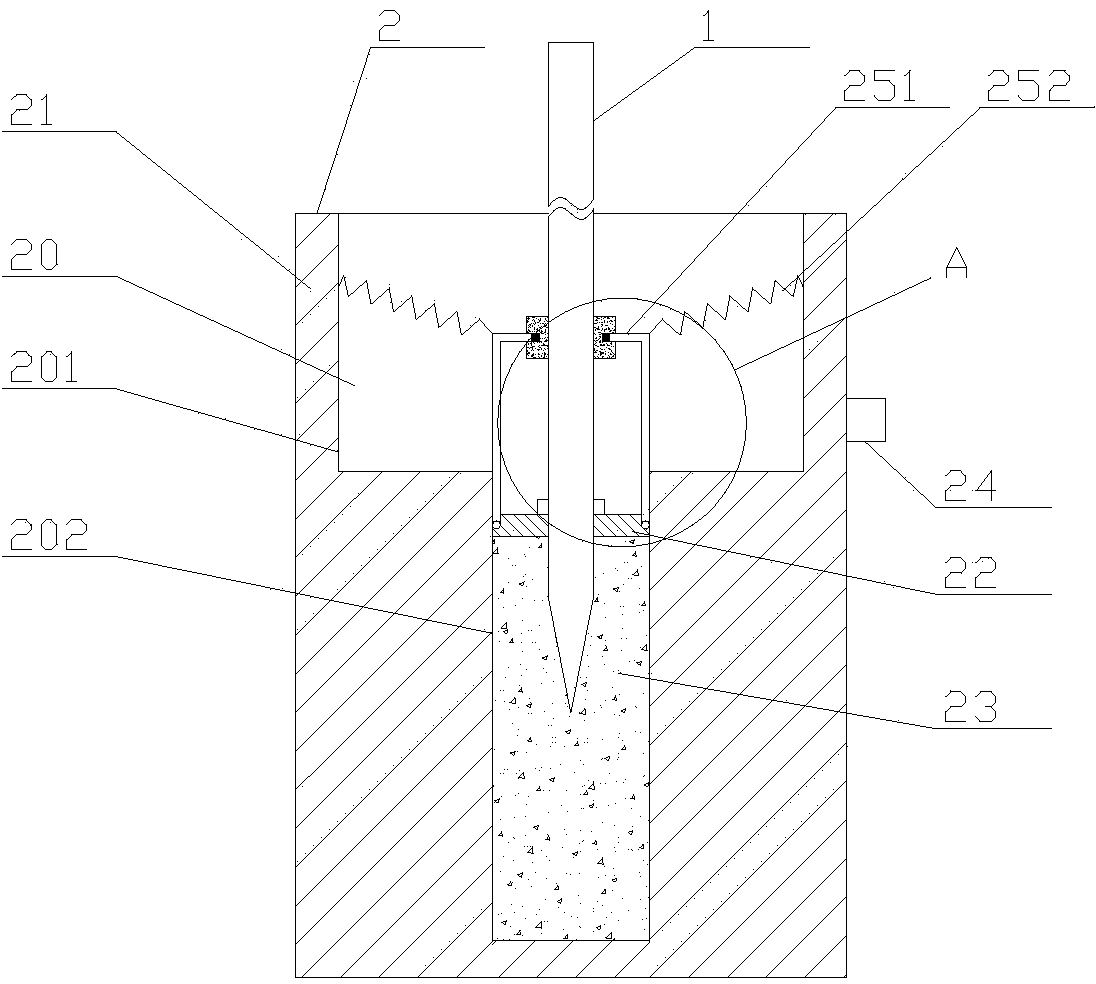

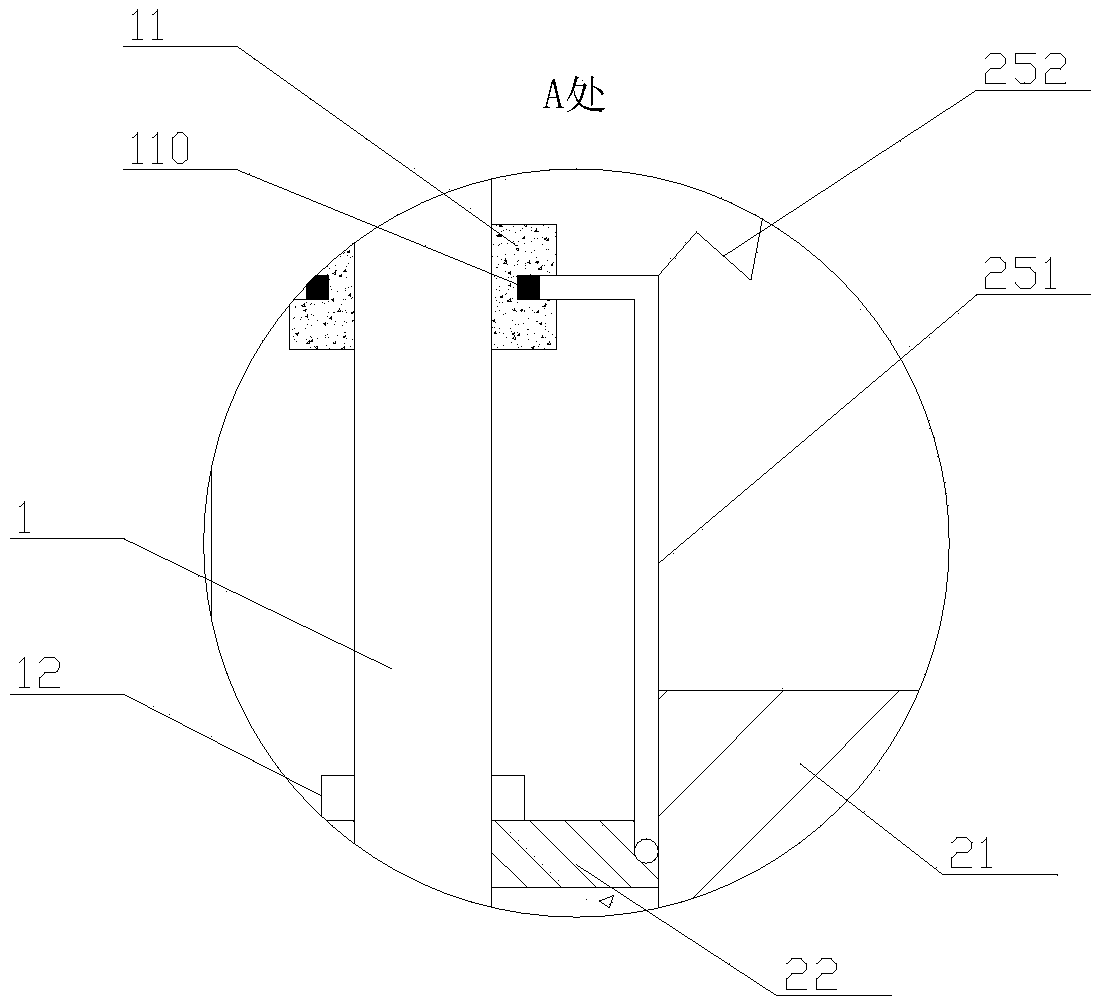

[0036] Embodiment one, such as Figure 1-3 As shown: the trigger assembly 25 includes a trigger lever 251 and a tension spring 252. The trigger lever 251 is in an inverted L shape and is made of conductive material. The trigger lever 251 is connected in series to the power supply Between the indicator light 24 , the trigger lever 1 251 includes a long rod and a short rod connected as one and perpendicular to each other, the bottom end of the long rod is hinged in the accommodation groove 222 of the clamp 22 , The tension spring one 252 is connected between the top end of the long rod and the inner wall of the upper slot 201 . Like this, when clamping plate moves downwards under the drive of grounding pin, a pair of long rods will break away from the pulling force of extension spring one under the effect of the notch of lower groove and turn upwards, thereby drive short rods to move together, and then make a pair of The short rod extends into the contact groove to make contact...

Embodiment 2

[0038] Embodiment two, such as Figure 7-9 As shown: the trigger assembly 25 includes a trigger lever 2 253, a tension spring 2 and a slide bar 255, the upper part of the trigger lever 2 253 is arc-shaped, and the bottom end of the trigger lever 2 253 is hinged on the In the accommodating groove 222, the trigger rod 253 is made of conductive material, the trigger rod 253 is connected in series between the power supply and the indicator light 24, the sliding rod 255 is semicircular, and The two ends of the slide bar 255 in a pair of trigger assemblies 25 are fixedly connected to each other, the slide bar 255 is accommodated on the top of the trigger lever 253, and the extension spring 2 is connected between the trigger lever 2 253 and the trigger lever 253. between the groove bottoms of the upper groove 201. Like this, when clamping plate moves downwards under the drive of ground pin, a pair of trigger lever two will want to upturn under the effect of the notch of lower groove...

Embodiment 3

[0040] Embodiment three, such as Figure 10-12 As shown: the trigger assembly 25 includes a trigger lever three 256 and a trigger lever four 257, the bottom end of the trigger lever three 256 is hinged in the accommodating groove 222 of the clamp 22, and the top end of the trigger lever three 256 is hinged In the middle part of the trigger lever 257, the bottom end of the trigger lever 257 is hinged on the inner wall of the upper groove 201. The trigger lever 257 is made of conductive material and connected in series between the power supply and the indication between lamps 24 . Like this, when clamping plate moves downwards under the drive of grounding pin, a pair of trigger rods 3 will turn up under the effect of the notch of the lower groove, thereby drive trigger rod 4 to turn down, and then make a pair of trigger rods 4 The top end of the pin extends into the contact groove to achieve contact with the contact piece, and finally lights up the indicator light; after the cl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap