Full-automatic paint spraying machine

A paint spraying machine, fully automatic technology, applied in the field of fully automatic paint spraying machines, can solve problems such as blank equipment, size adjustment of glass to be processed, and unstable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

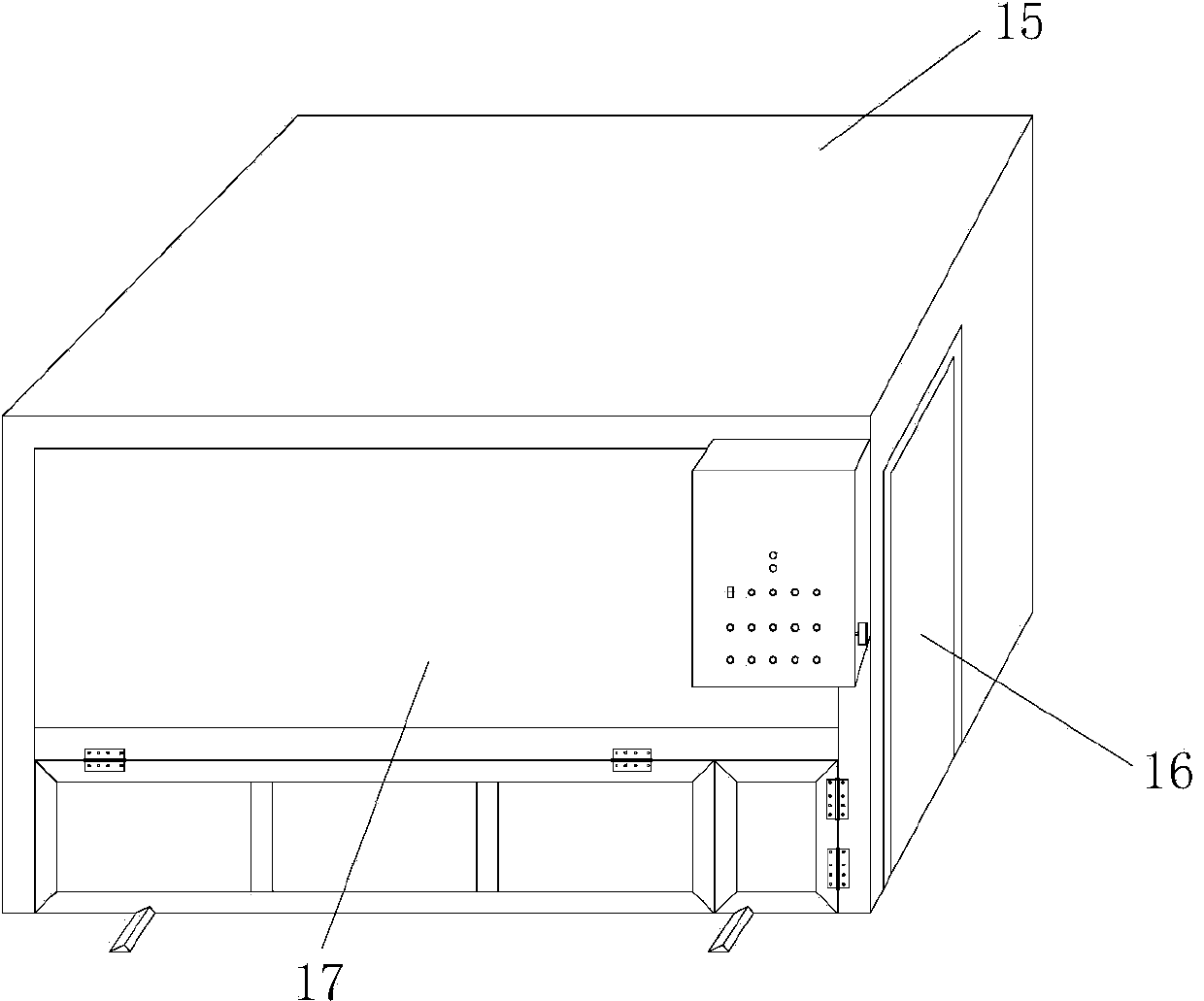

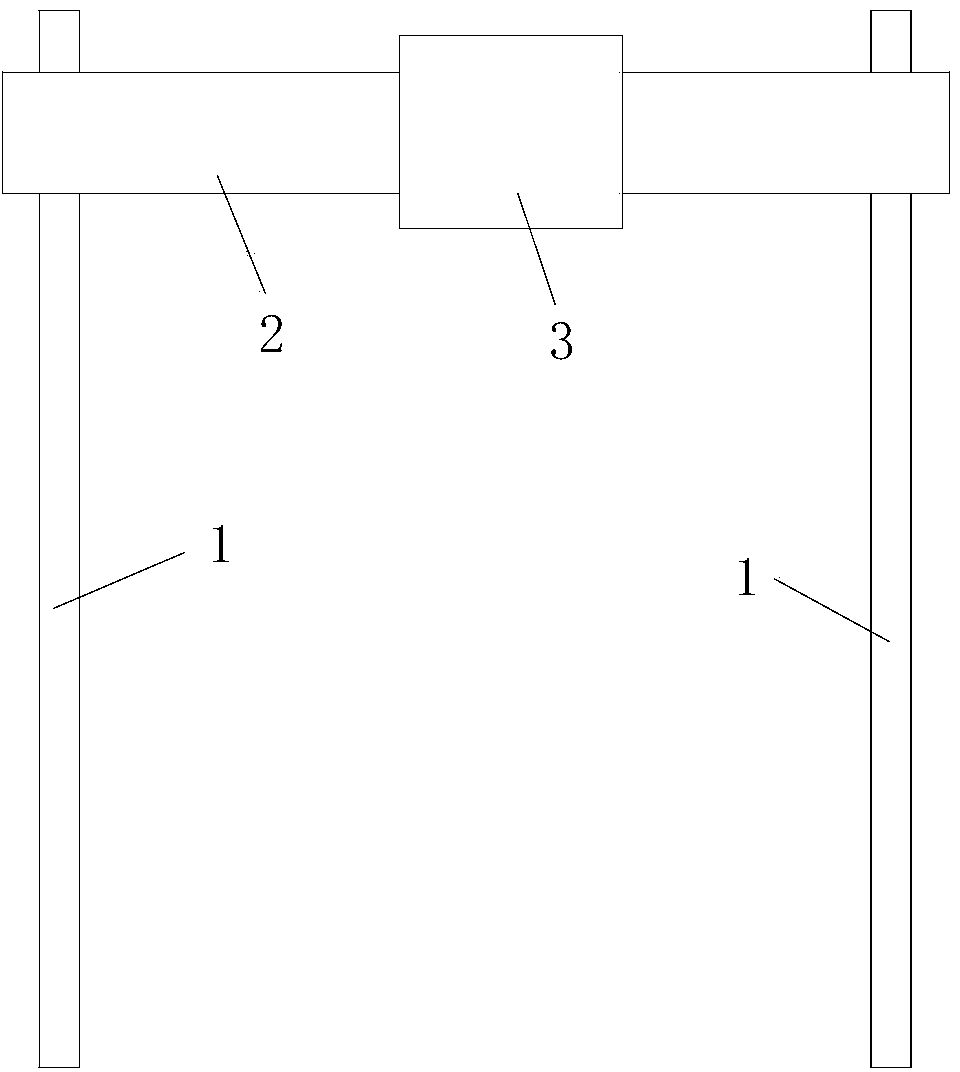

[0028] like figure 1 and Figure 4 As shown, the fully automatic painting machine in this embodiment includes a painting device, and the painting device includes a frame and a transmission mechanism arranged on the frame.

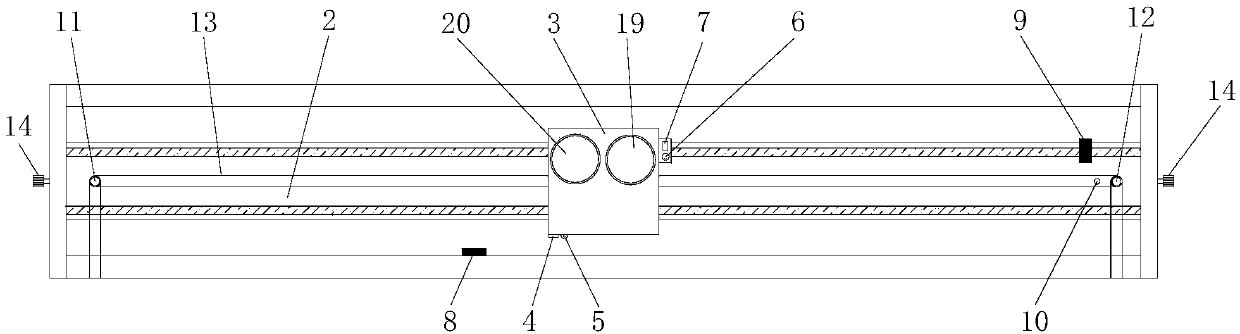

[0029] The transmission mechanism includes a frame, a guide rail 1 arranged on the frame along the Y direction, a horizontal frame 2 whose length is arranged on the guide rail 1 along the X direction and can move along the Y direction on the guide rail 1, and a horizontal frame 2 that can move along the X direction. The sliding part 3 on the horizontal frame 2 is provided with at least two sensing parts on the horizontal frame 2, at least one of the at least two sensing parts is movably or detachably arranged on the horizontal frame 2, and the sliding part 3 is provided with a At least one spray gun 18 for spraying paint, when one of the at least two sensing elements is sensed, the first sensor 4 that controls the sliding part 3 to move in the opposite di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com