Seedling feeding mechanism of horizontal seedling tray automatic transplanting machine

A transplanting machine, fully automatic technology, applied in the field of transplanting machines, can solve the problems of high labor intensity and low operating efficiency, and achieve the effect of reliable and stable system, uniform force, and improved transplanting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

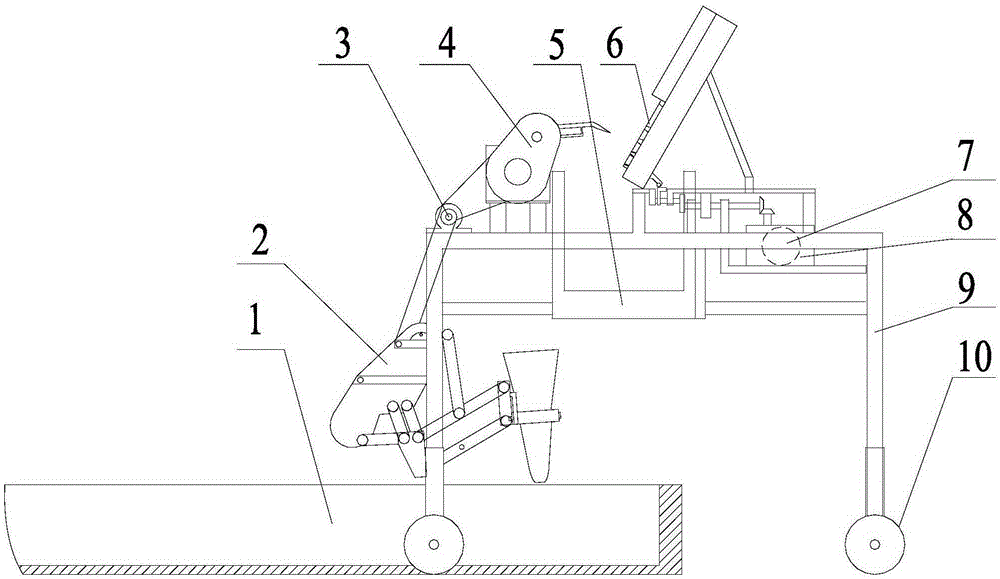

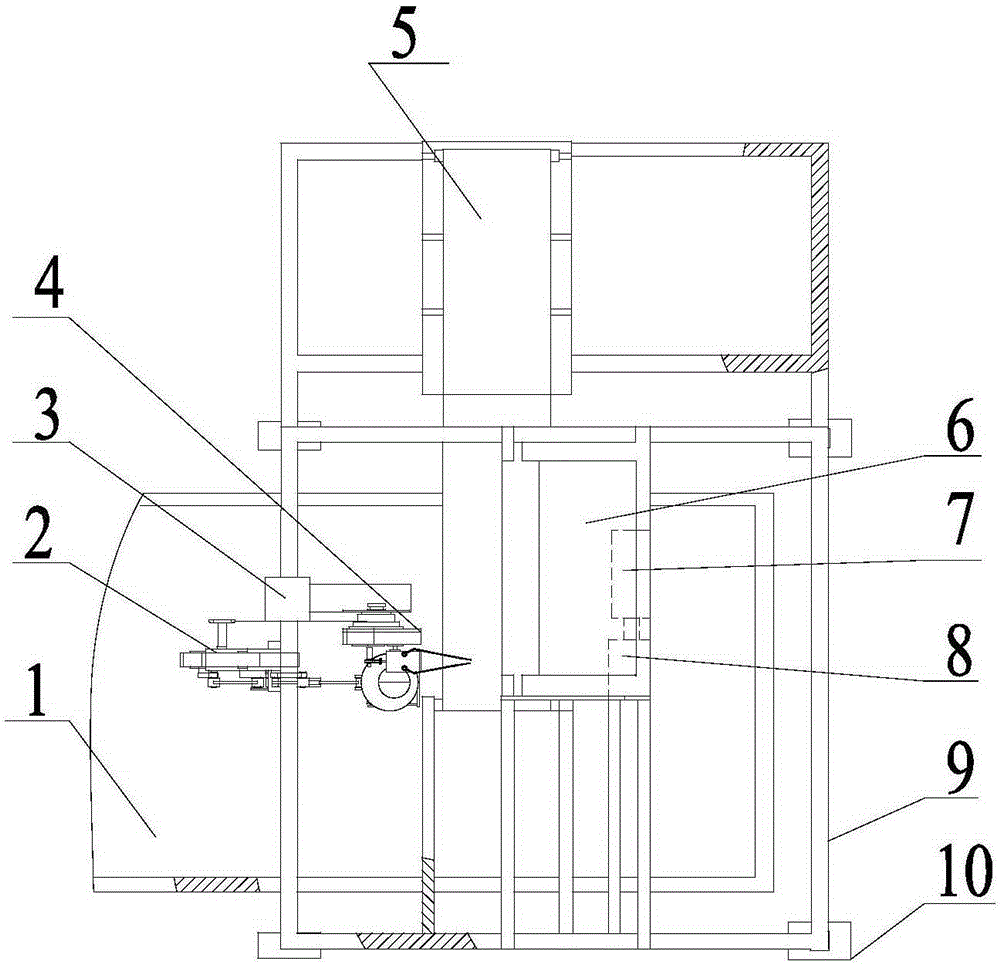

[0034] see Figure 1 to Figure 5 , a kind of seedling tray horizontal automatic transplanting machine seedling delivery mechanism test bench, including soil tank 1, planting mechanism 2, motor 3, seedling retrieval mechanism 4, seedling tray recovery assembly 5, seedling delivery mechanism 6, driving motor 7, Cam divider 8, frame 9, traveling wheel 10. Wherein the planting mechanism 2 and the seedling-taking mechanism 4 are comparatively mature technologies on the existing transplanting machine, so they will not be repeated here.

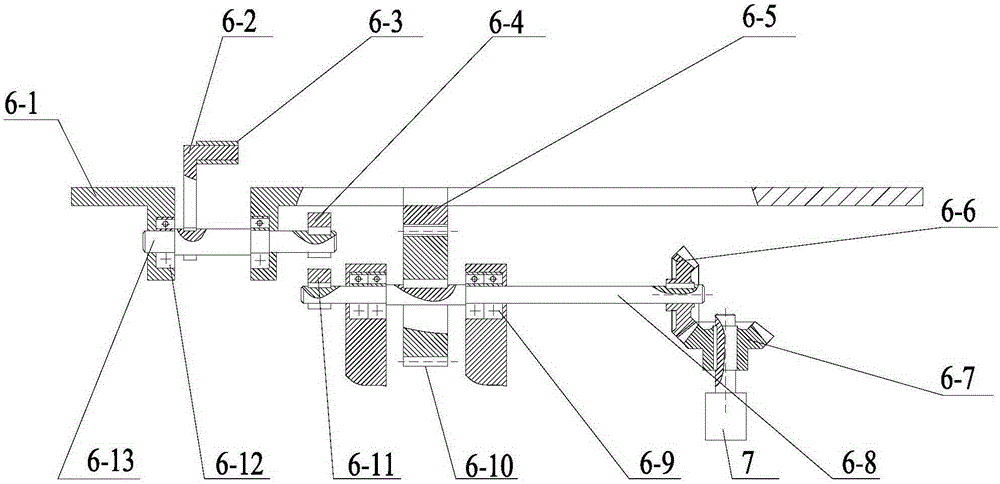

[0035] see in conjunction Figure 3-9 The seedling delivery mechanism 6 on the above-mentioned transplanting machine test bench includes a seedling tray support 6-1 which is arranged on the transplanting machine frame 9 and which can move laterally and a seedling tray which is arranged on the transplanting machine frame 9 and which can move longitudinally. plate, the two sides of the seedling plate support 6-1 are provided with a longitudinal chai...

Embodiment 2

[0040] as attached Figure 8 As shown, the seedling tray can also adopt a floating seedling tray made of hard foam, and the sprockets of the chain drive mechanism on both sides of the seedling tray support 6-1 are located in the same plane, because the direction of the sprocket just coincides with the implementation In Example 1, the setting direction of the pot seedling seedling plate is vertical, so in the present embodiment, bevel gear pairs are provided with the setting direction (not shown) of the chain transmission mechanism between the ratchet mechanism and the cam transmission mechanism. Both sides of the seedling tray support 6-1 are provided with longitudinal baffles 6-26, both sides of the floating seedling raising tray 12 are clamped between the baffles 6-26, and the chain 6-19 of the chain transmission mechanism is located Between the baffle plate 6-26 and the side wall of the floating seedling raising tray 12, the chain 6-19 drives the floating seedling raising t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com