Emulsification stirring apparatus

A stirring device and stirring shaft technology are applied in mixers with rotating stirring devices, chemical instruments and methods, dissolution and other directions, which can solve the problems of insufficient uniform stirring in an emulsifier, and achieve the effect of faster reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

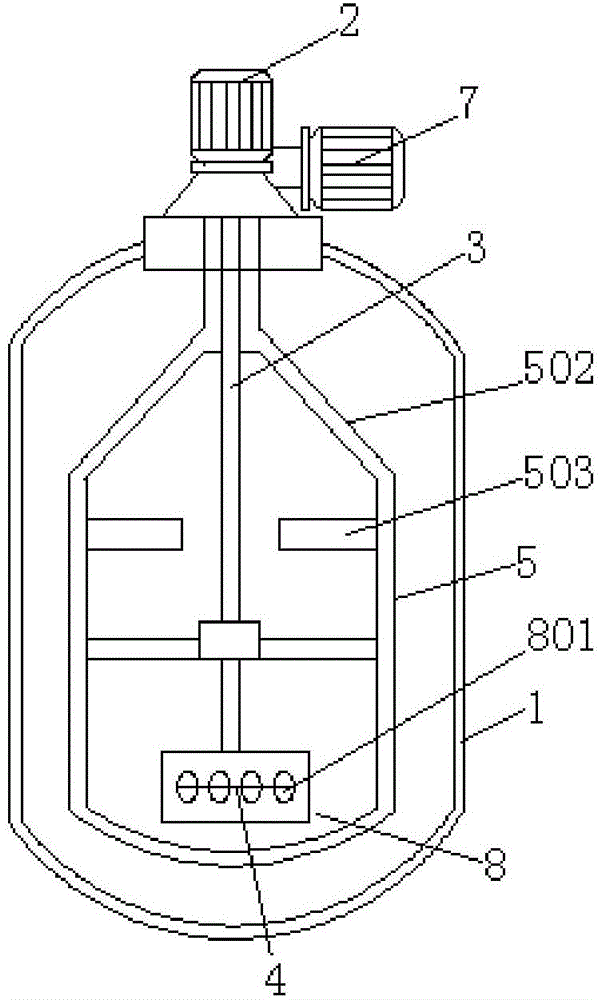

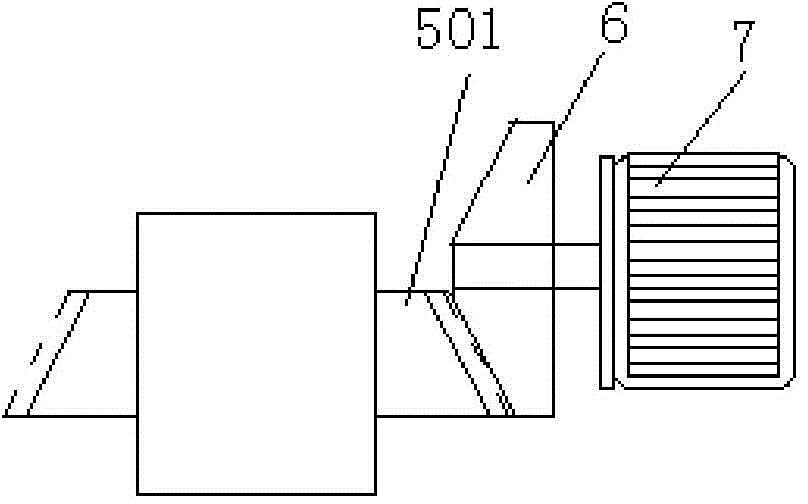

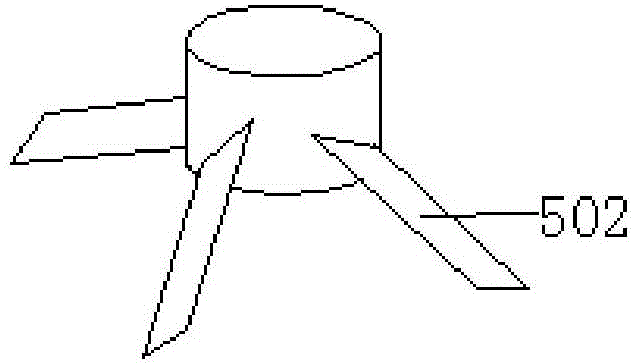

[0013] Referring to accompanying drawing, a kind of emulsification stirring device comprises reaction vessel 1, high-shear emulsification motor 2 and stirring shaft 3, and stirring shaft 3 is arranged in the reaction vessel 1, and rotating stator 4 is fixedly installed at the lower end of stirring shaft 3, and described stirring The shaft 3 is connected to the driving shaft of the high-shear emulsification motor 2, and there is a stirring frame 5 in the reaction vessel 1. The upper end of the stirring frame is cylindrical, and a gear ring 501 is arranged on the periphery of the cylinder, and a rotating gear 6 is meshed on the gear ring. The gear 6 is fixed on the transverse motor 7, the upper end of the stirring frame is composed of three stirring ribs 502, and the three stirring ribs are distributed in a triangular spiral shape, and the rotating stator is equipped with a fixed cover 8, which is distributed around the circumference There are a plurality of fixing holes 801, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com