scroll compressor

A technology of scroll compressors and compression chambers, which is applied in the direction of rotary piston machines, rotary piston pumps, mechanical equipment, etc., can solve problems such as insufficient oil supply, and achieve the effect of rationalizing the oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

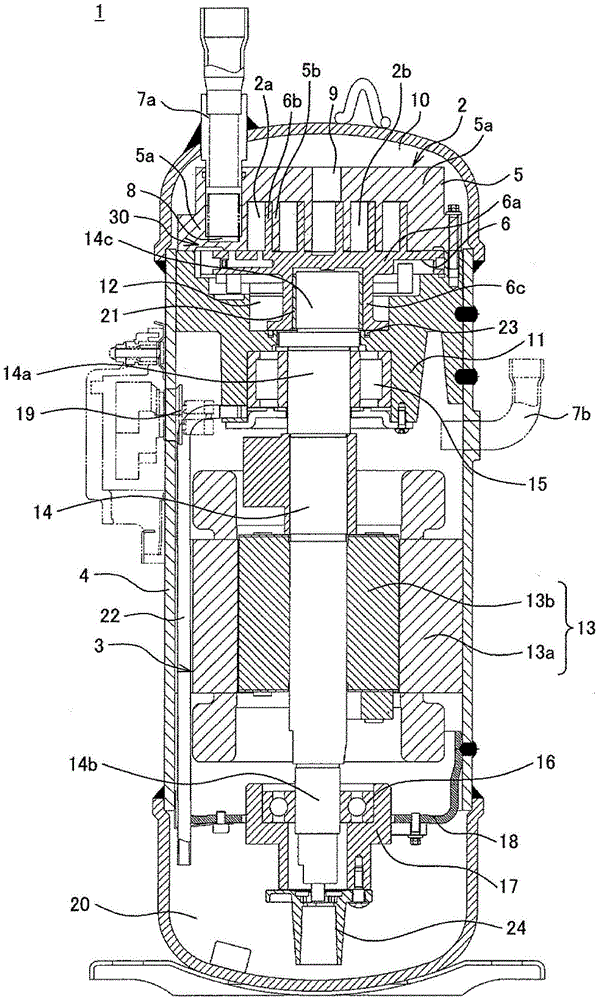

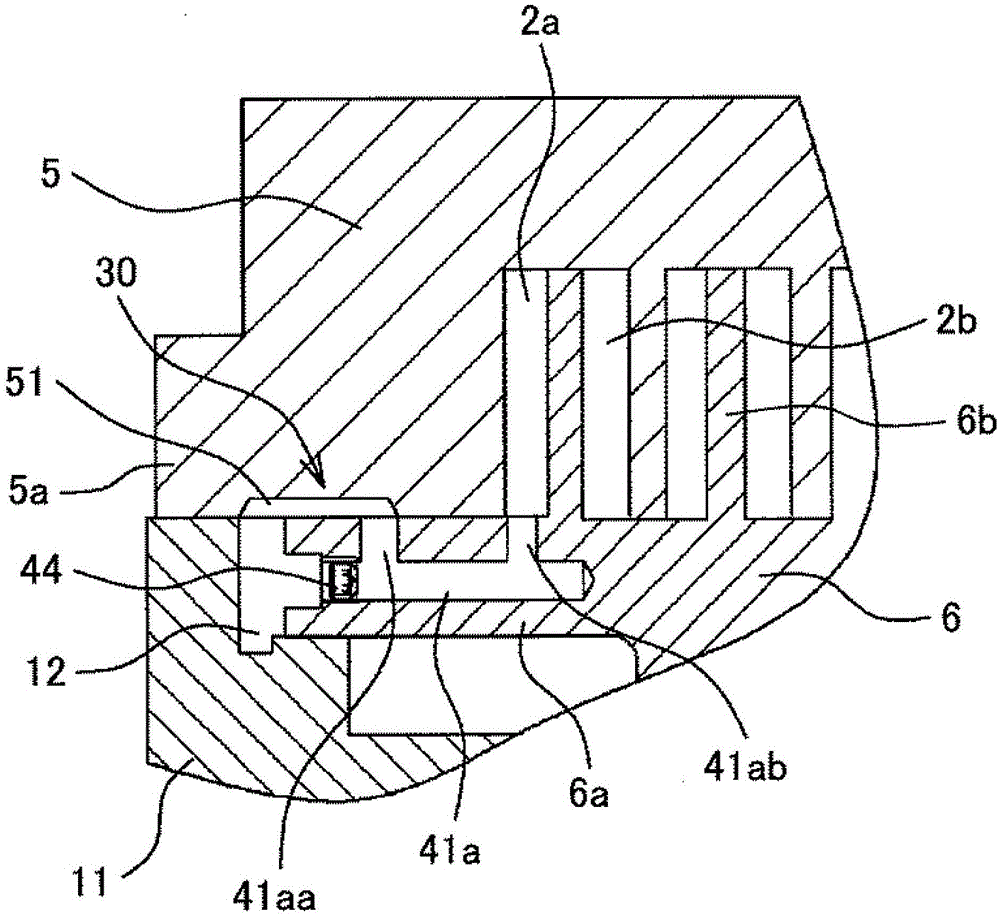

[0053] use Figure 1 ~ Figure 6 The first embodiment of the scroll compressor of the present invention will be described.

[0054] figure 1 It is a longitudinal cross-sectional view showing Embodiment 1 of the scroll compressor of the present invention, and shows the overall structure of the scroll compressor. The scroll compressor 1 of the present embodiment is configured to house a compression section 2 arranged at the upper part and a drive section 3 arranged at the lower part and drive the compression part in a closed container 4.

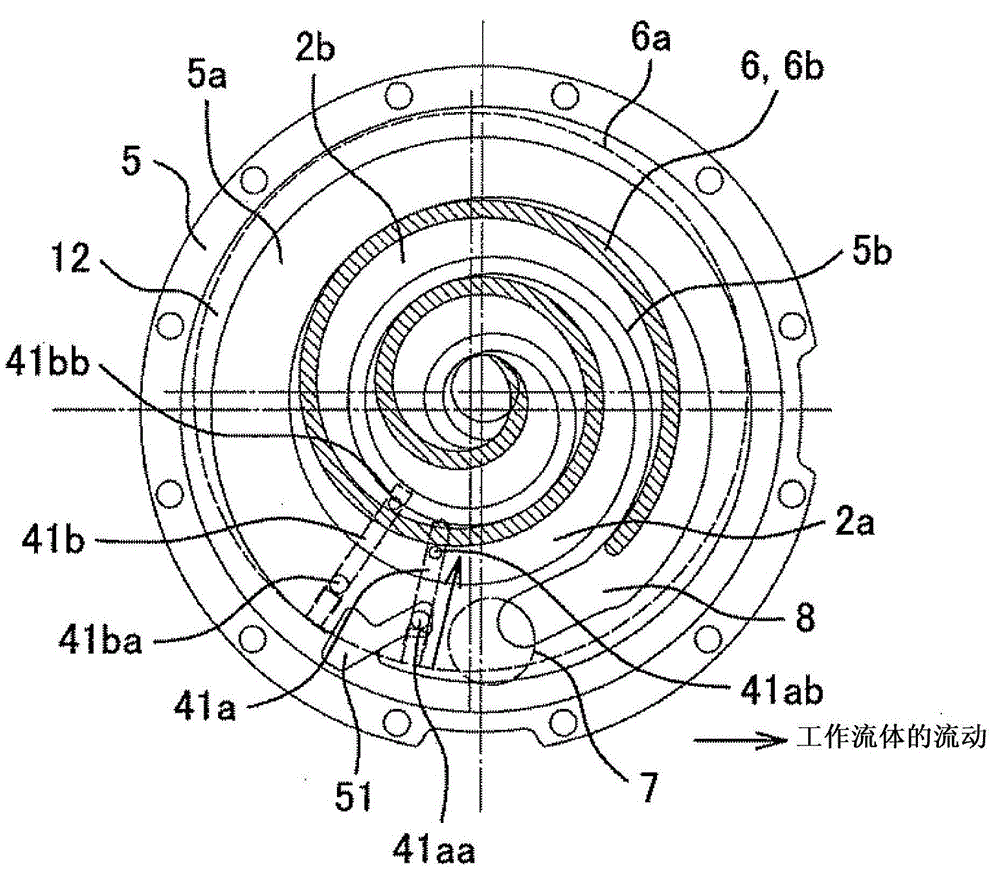

[0055] The compression part 2 is configured such that a fixed scroll 5 formed by erecting a spiral winding plate 5b on the platen 5a and an orbiting scroll 6 formed by erecting a spiral winding plate 6b on the platen 6a Meshing. As a result, the outer line side compression chamber 2a and the inner line side compression chamber 2b of the orbiting scroll wrap 6b are formed between the two scrolls 5 and 6, and the orbiting scroll 6 is orbited by the d...

Embodiment 2

[0102] use Picture 9 and Picture 10 The second embodiment of the scroll compressor of the present invention will be described. Picture 9 It is a diagram illustrating Embodiment 2 of the scroll compressor of the present invention, and is a plan view of the orbiting scroll viewed from the side of the winding plate. Picture 10 It is a diagram illustrating the relationship between the swing angle and the pressure in the compression chamber in Example 2 of the present invention, and is a diagram illustrating the communication section of the fluid outflow path of the back pressure chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com