cylinder lock

A cylinder type, lock technology, applied in the field of door latch components, can solve the problems of weak handle holding force, hard spring, etc., and achieve the effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

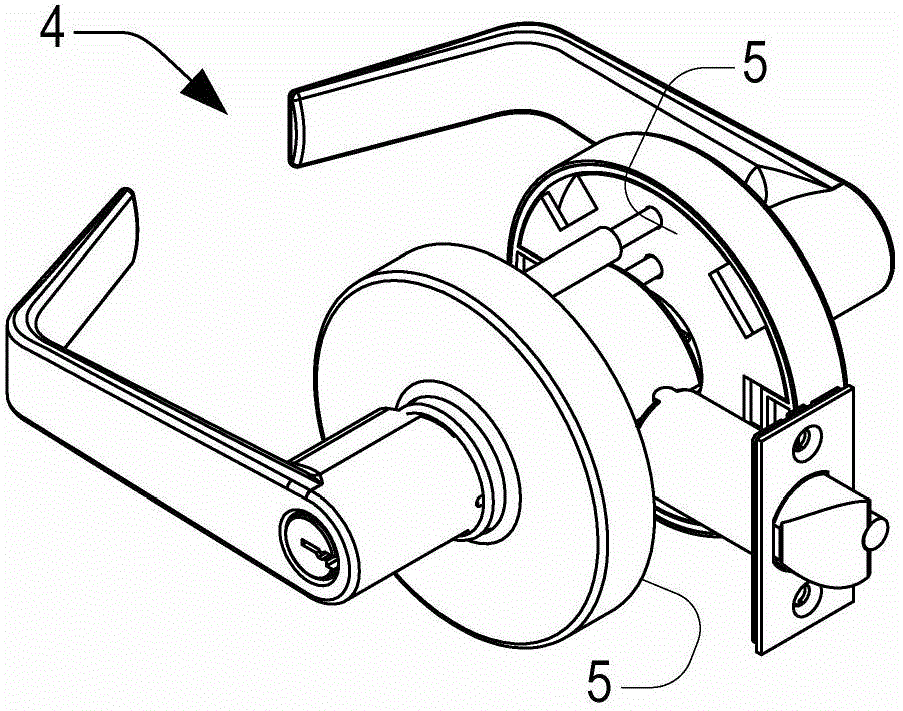

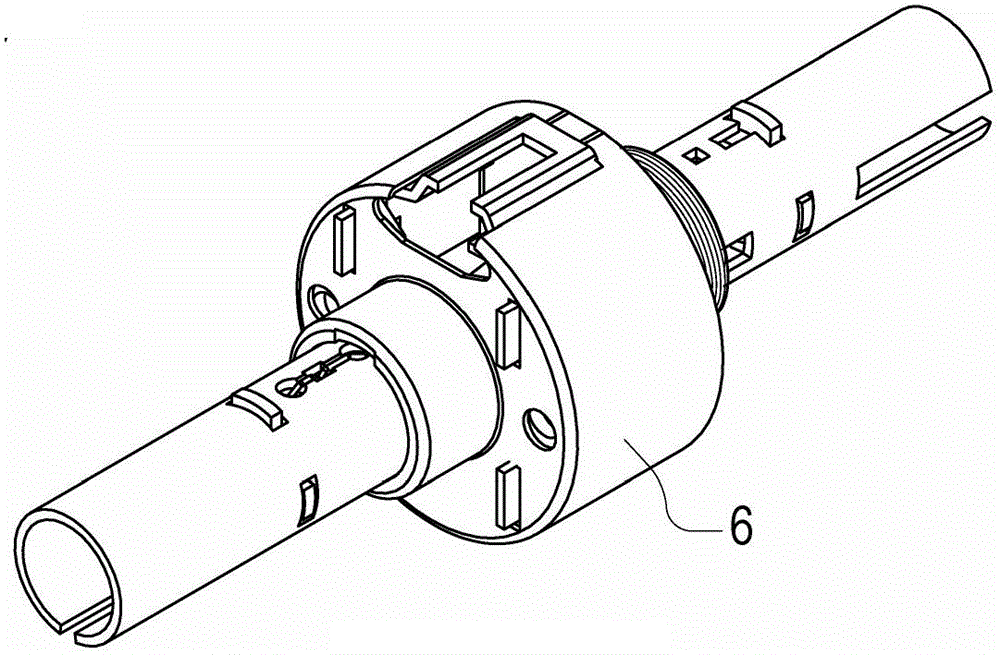

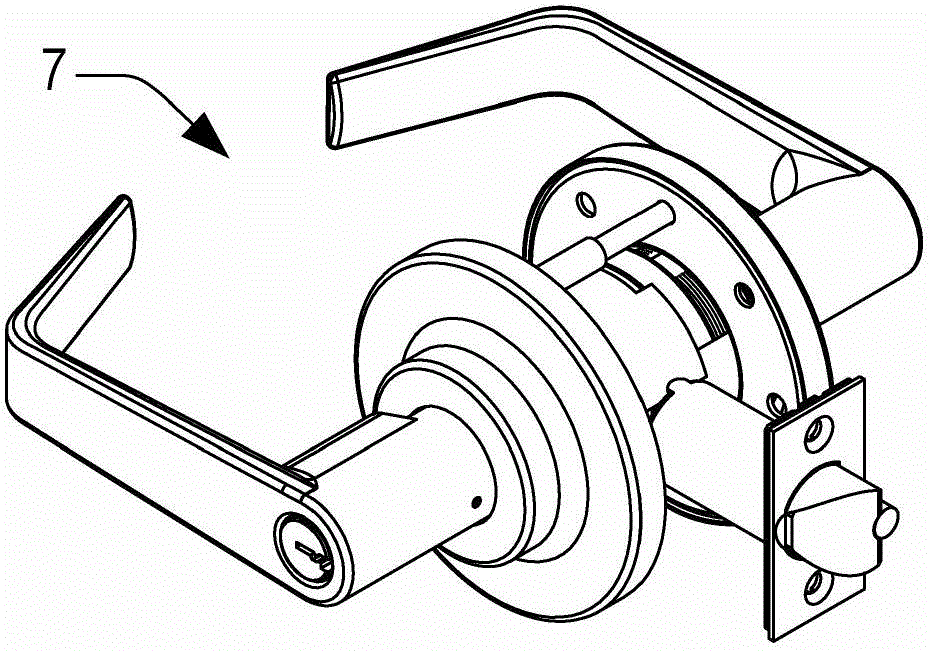

[0143] Figure 5 to Figure 41 and Figure 43 to Figure 51 Various embodiments and aspects of a cylinder lock (or key cylinder assembly) 10 supporting multiple lock functions are shown. The cylinder lock 10 is preferably made of steel and, despite its light weight and extensive use of sheet metal, complies with Drilled and Preassembled Locks and Latchlocks for Class 1 Locks ANSI / BHMAA 156.2-2003. Requirements (the specification of which is incorporated by reference). The cylinder lock 10 includes a lock chassis assembly 18, torque plate 110, key arbor assembly 140, inside handle knob stem subassembly 200, key cylinder 215, cylinder handle carrying arbors 70 and 80, latch bolt assembly 280, and trim (disc insert 220, disc insert 230, disc 240, and internally threaded disc collar 245). The cylinder lock 10 described herein is suitable for a range of standard door widths, for example between 13 / 4" and 2" thick doors.

[0144] Focus first on the lock chassis assembly 18 . Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com