Impeller for an exhaust gas turbocharger, exhaust gas turbocharger and method for balancing a rotor arrangement of an exhaust gas turbocharger

A technology for exhaust gas turbines and compressor rotors, which is applied to components of pumping devices for elastic fluids, gas turbine devices, static/dynamic balance testing, etc., to achieve the effect of reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

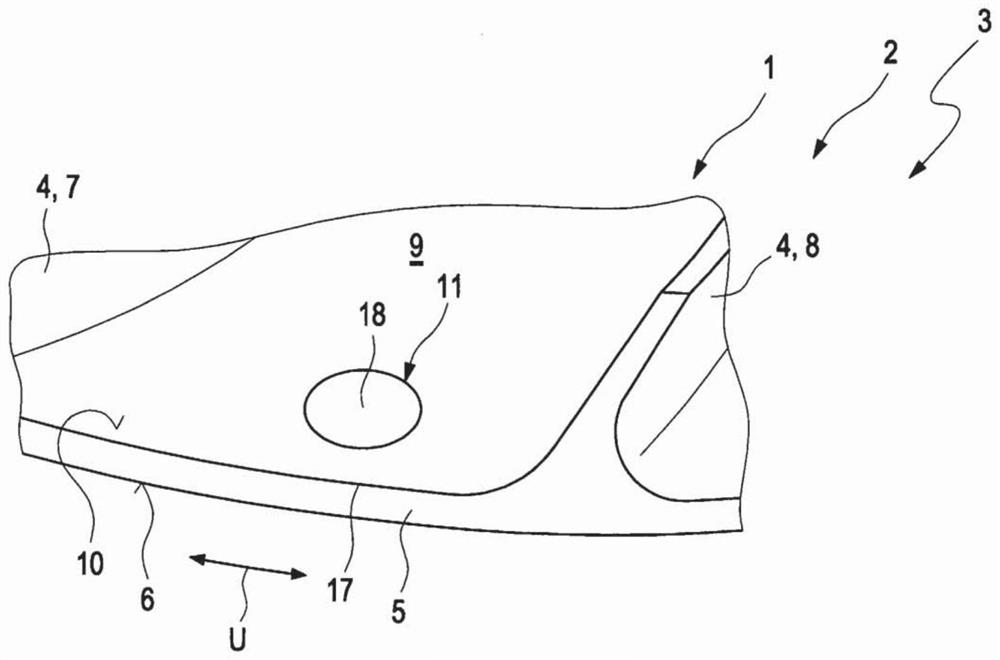

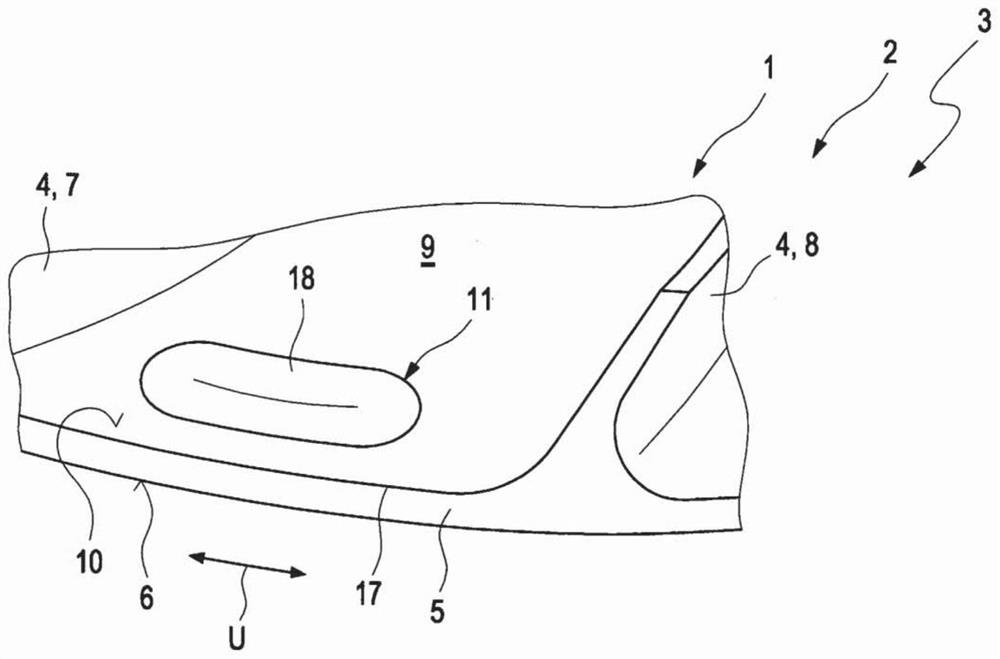

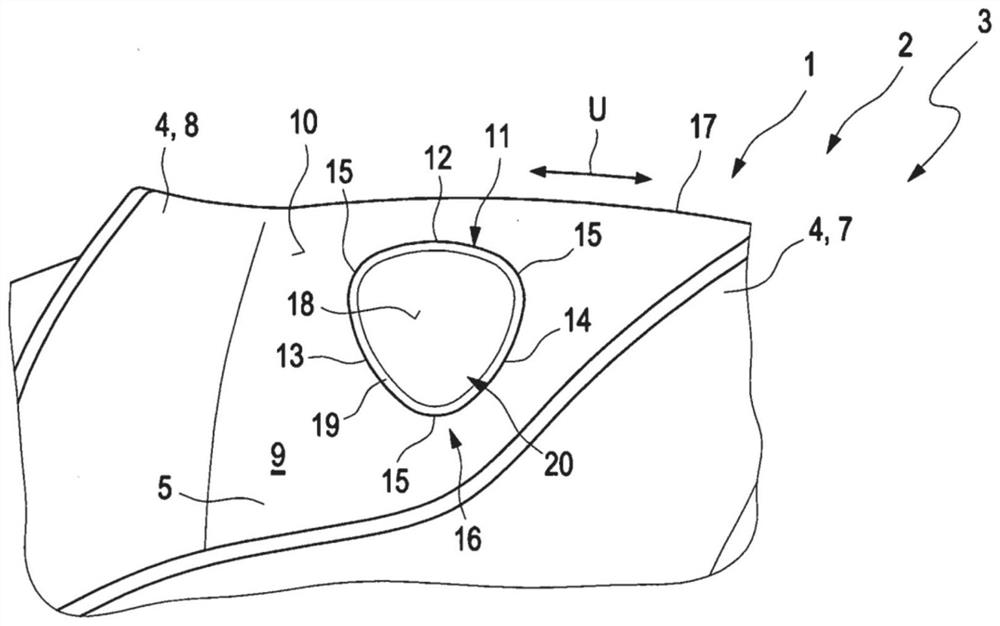

[0028] The impeller 1 of a rotor arrangement 2 for an exhaust gas turbocharger 3 according to the prior art is designed according to FIG. 1 . The impeller 1 is designed in the form of a compressor rotor. The rotor arrangement 2 comprises a compressor rotor 1 and a turbine rotor (not shown in detail), which is connected in a rotationally fixed manner to the compressor rotor 1 via a shaft (not shown in detail).

[0029] The rotor arrangement 2 is mounted rotatably in a bearing section (not shown in detail) of the exhaust gas turbocharger 3 about a rotation axis (not shown in detail) of the rotor arrangement 2 . The turbine rotor is accommodated rotatably in a non-detailed exhaust gas guide section of the exhaust gas turbocharger 3 through which flow can flow. The turbine rotor is impinged on and rotated by exhaust gas from an internal combustion engine, not shown in detail, which is flow-through-connected to the exhaust gas turbocharger 3 , via inlet channels (not shown) of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com