Direction changeable type tapping mechanism

A body and crank technology, which is used in mechanical equipment, metal processing mechanical parts, gear transmission devices, etc., can solve problems such as poor reliability, shortened motor life, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

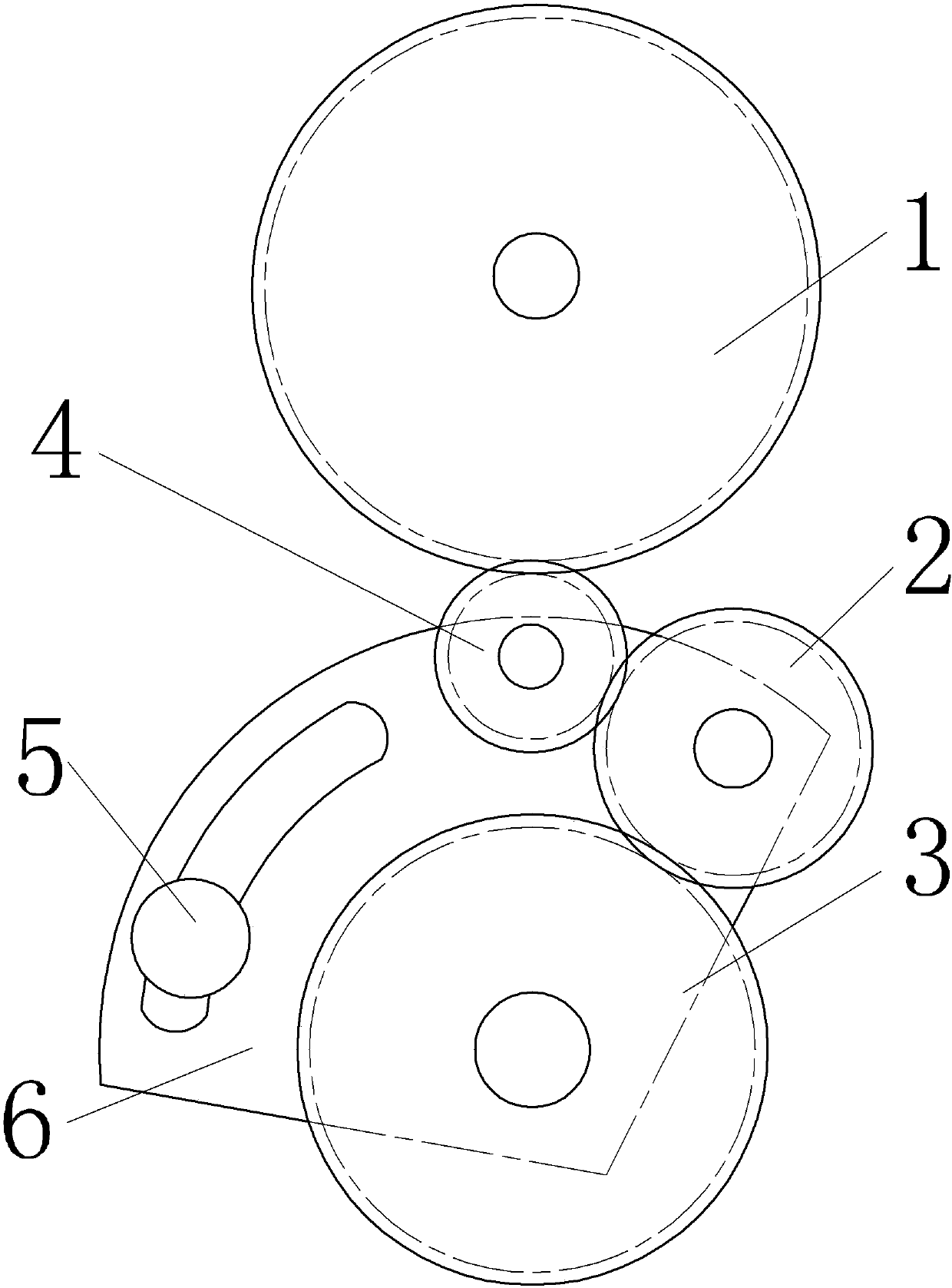

[0008] The reference signs in the accompanying drawings of the specification include: output gear 1 , first transmission gear 2 , input gear 3 , second transmission gear 4 , limit pin 5 , and rocker 6 .

[0009] Below in conjunction with accompanying drawing and embodiment technical solution of the present invention is described in further detail:

[0010] Such as figure 1 As shown, the reversible tapping mechanism of an embodiment of the present invention includes an input gear 3 , an output gear 1 , a rocker 6 and a first transmission gear 2 and a second transmission gear 4 meshing with each other. The rocker 6 is a fan-shaped structure, and the end of the rocker 6 is hinged with the body. There is an arc-shaped steering groove near the fan-shaped edge of the rocker 6, and a limit stop pin connected to the body with an interference fit is snapped into the steering groove. 5. The first transmission gear 2 and the second transmission gear 4 are located near the fan-shaped ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com