Welding deformation real-time detection system and its detection method

A technology for real-time detection and welding deformation, applied in measuring devices, instruments, optical devices, etc., to achieve high application efficiency, solve real-time detection problems, and high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

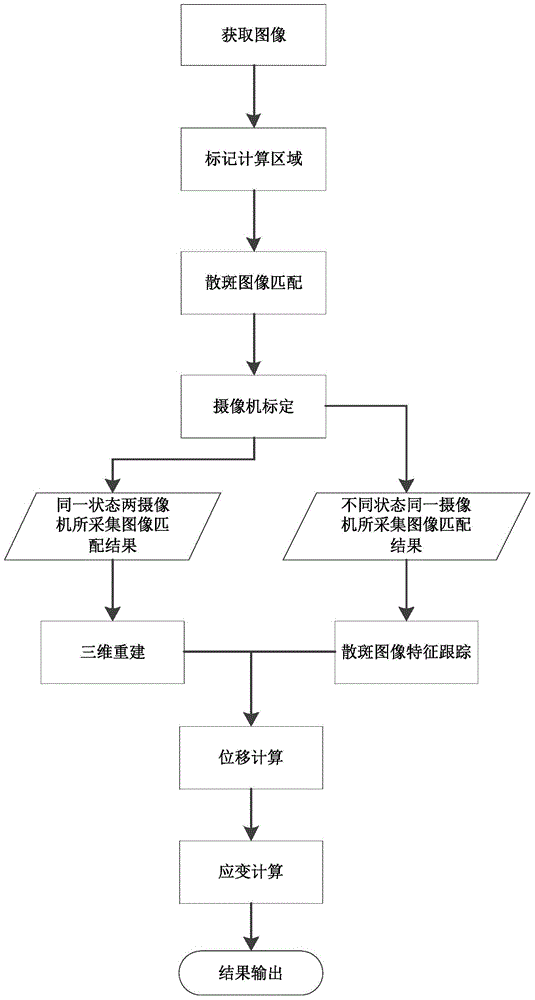

Method used

Image

Examples

Embodiment

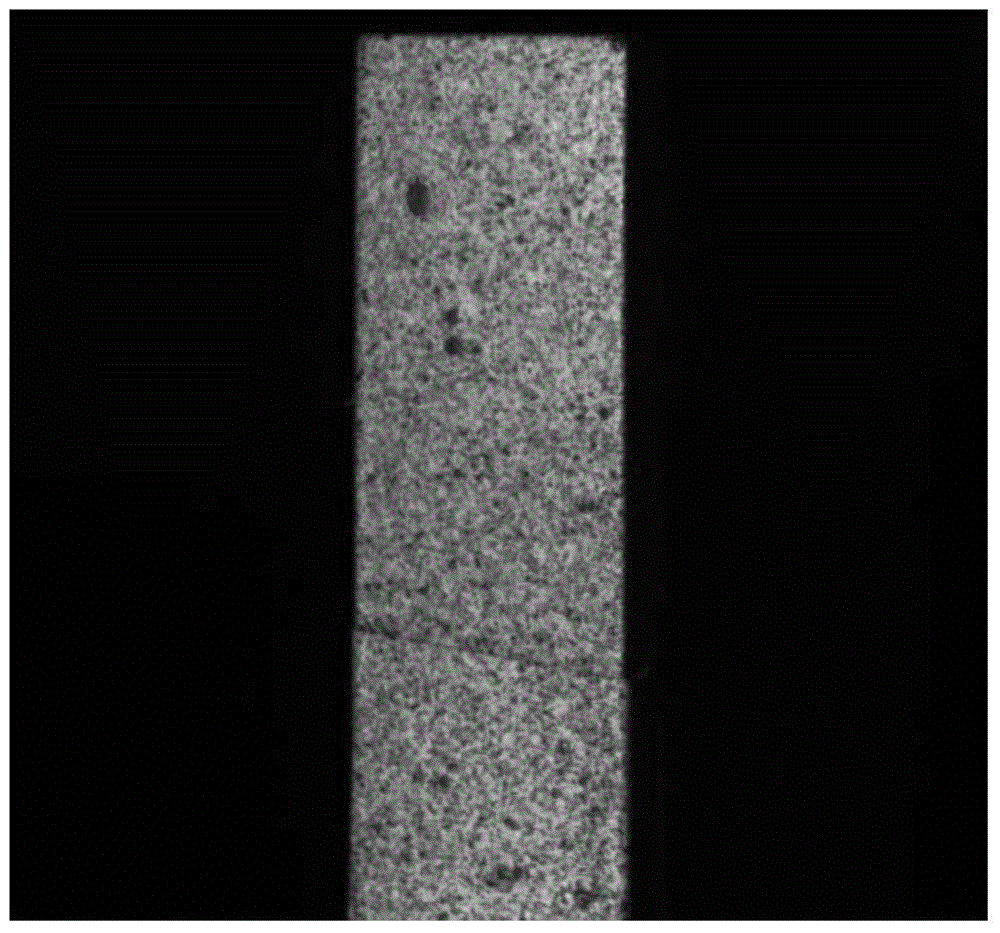

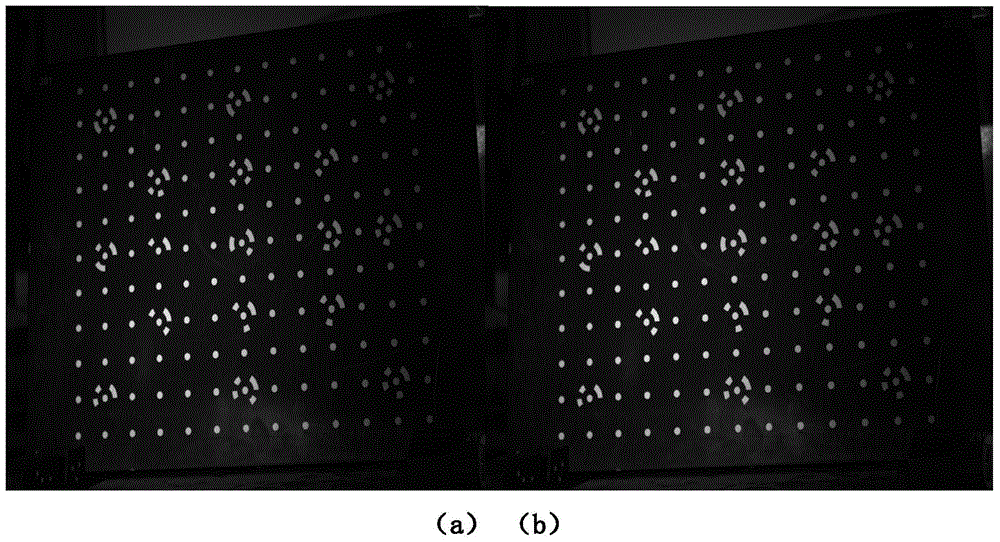

[0051] The welding deformation real-time detection system adopted in this embodiment includes a speckle field generated on the surface of the irradiated welding workpiece to form a speckle image, and then a CCD camera for collecting speckle images at various stages of welding on the surface of the welding workpiece. 5. Process the collected speckle images, and identify the three-dimensional coordinate changes of the deformation points on the surface of the welding workpiece on the speckle images of each stage to obtain the three-dimensional surface of the welding workpiece The detection module of the displacement field and the strain field, and the control module that provides power support for the CCD camera and controls the image acquisition process. The CCD camera (4) is erected on the camera support (3), and the camera support is installed on the lifting platform (1) through the rotating platform (2); the lifting platform (1) drives the CCD camera (4) to carry out Move up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com