Engine power output rotary shaft torque signal matching box resistance detection circuit

A technology for engine power and resistance detection, applied in the direction of measuring resistance/reactance/impedance, measuring devices, measuring electrical variables, etc., can solve problems such as excessive working current, high temperature, short-circuit damage of external matching box deviation resistance, etc., to achieve Improved efficiency and accurate output voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

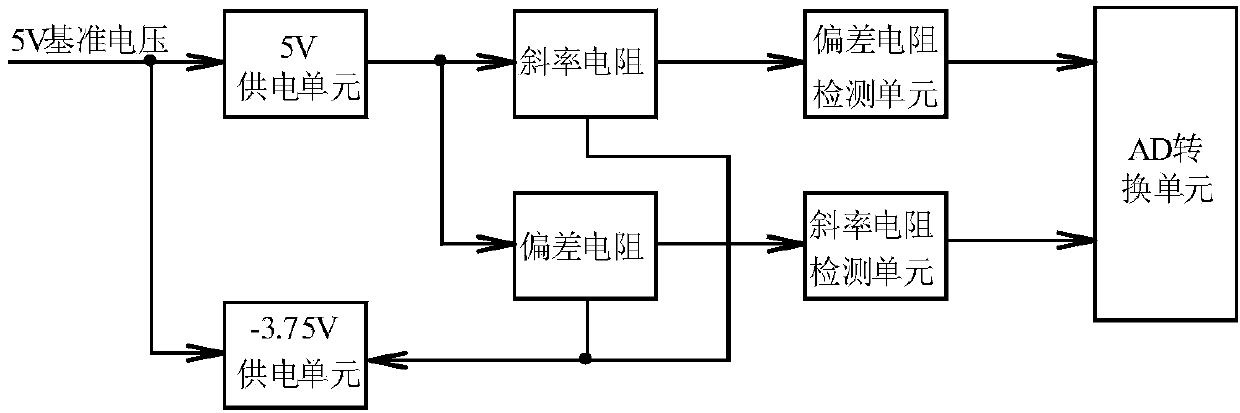

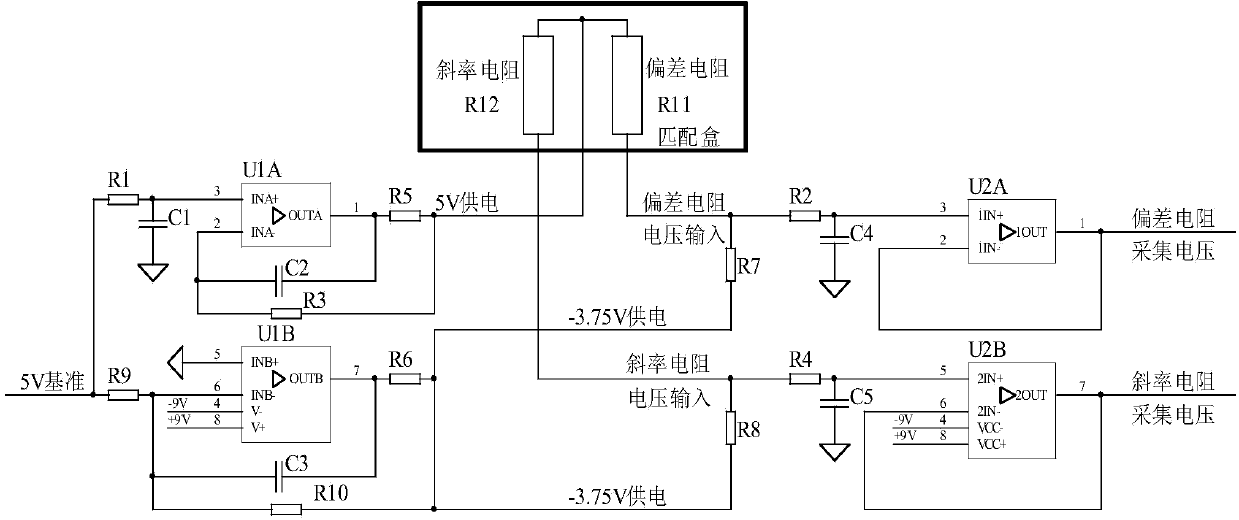

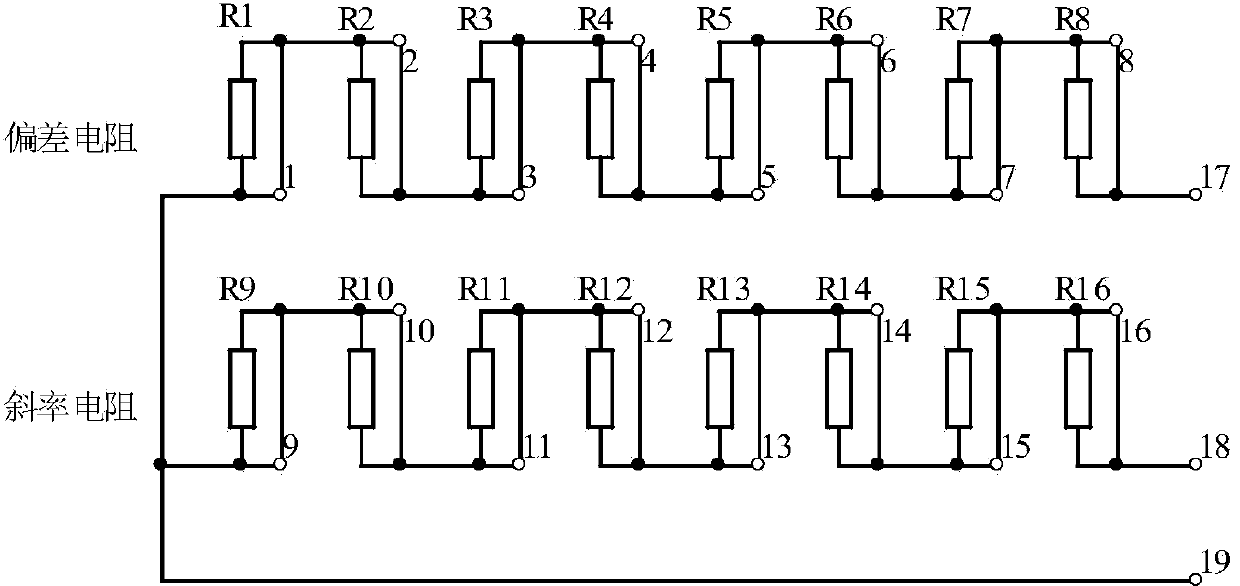

[0013] refer to figure 1 . Engine power output shaft torque signal matching box resistance detection circuit is mainly composed of 5V power supply unit, -3.75V power supply unit, slope resistance detection unit, deviation resistance detection unit and AD conversion unit. The 5V power supply unit sends the 5V reference voltage to the AD conversion unit for digital-to-analog conversion through the slope resistance and the deviation resistance detection unit. The -3.75V power supply unit forms a closed loop through parallel connection of the deviation resistance and the slope resistance. On the contact between the slope resistors, the 5V reference voltage is sent to the AD conversion unit through the slope resistance detection unit for digital-to-analog conversion. The engine electronic controller calculates the deviation resistance and slope according to the voltage converted by the AD conversion unit and the resistance series formula. The resistance value of the resistor.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com