Optical lens achieving temperature compensation

An optical lens and temperature compensation technology, applied in the field of optical lens, can solve problems such as large impact, unsatisfactory imaging clarity, poor temperature compensation performance, etc., and achieve high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

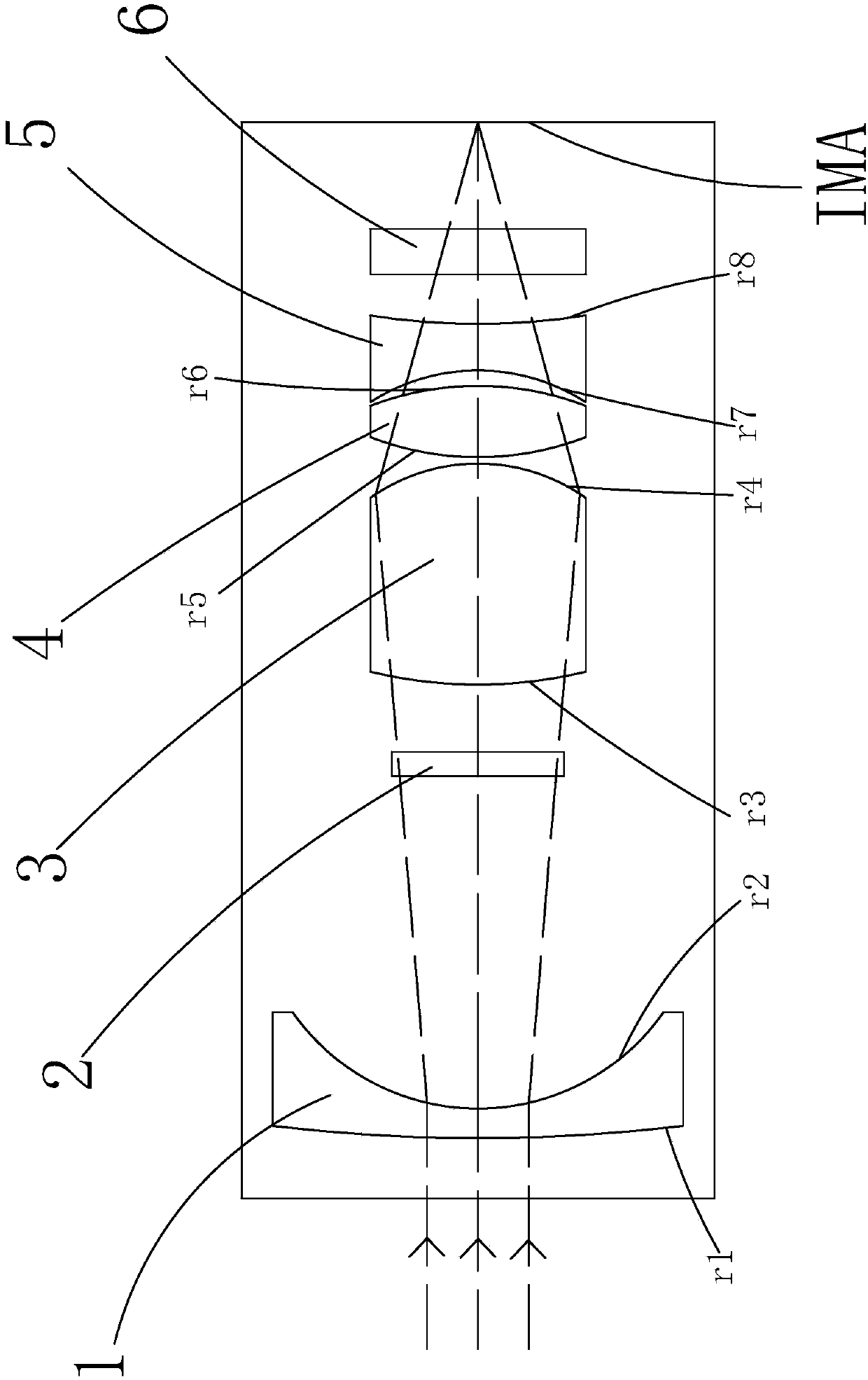

[0038] Such as figure 1 As shown, an optical lens for realizing temperature compensation includes a lens housing, and a lens made of optical glass and / or optical resin is arranged in the lens housing from the object side to the image side, including in turn:

[0039] The first lens 1 has a straw hat lens with negative power;

[0040] The second lens 3 has a biconvex lens with positive power;

[0041] The third lens 4, which has a biconvex lens with positive refractive power;

[0042] The fourth lens 5, which has a biconcave lens with negative power;

[0043] A diaphragm element 2 is arranged between the first lens 1 and the second lens 3, the fourth lens 5 is optically connected with a color filter 6, and the visible light band and the near-infrared band introduced by the lens are focused on the same focal plane , enabling clear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com