Dustproof harvester

A harvester, dust-proof technology, applied in harvesters, cutters, crop processors, etc., can solve problems such as affecting arable land operations, inhalation of debris into the lungs, safety accidents, etc., to accelerate the rate of decay and be beneficial to the environment. The effect of protection and avoidance of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

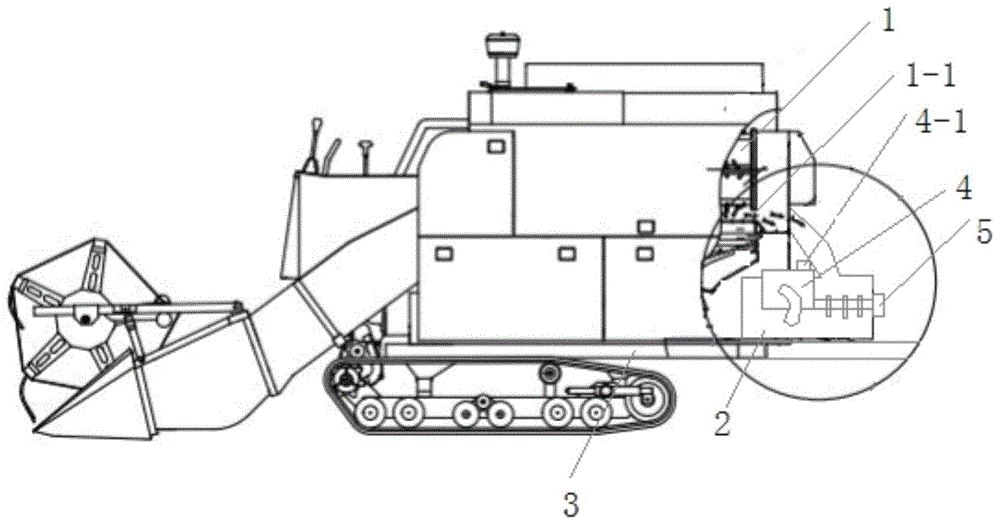

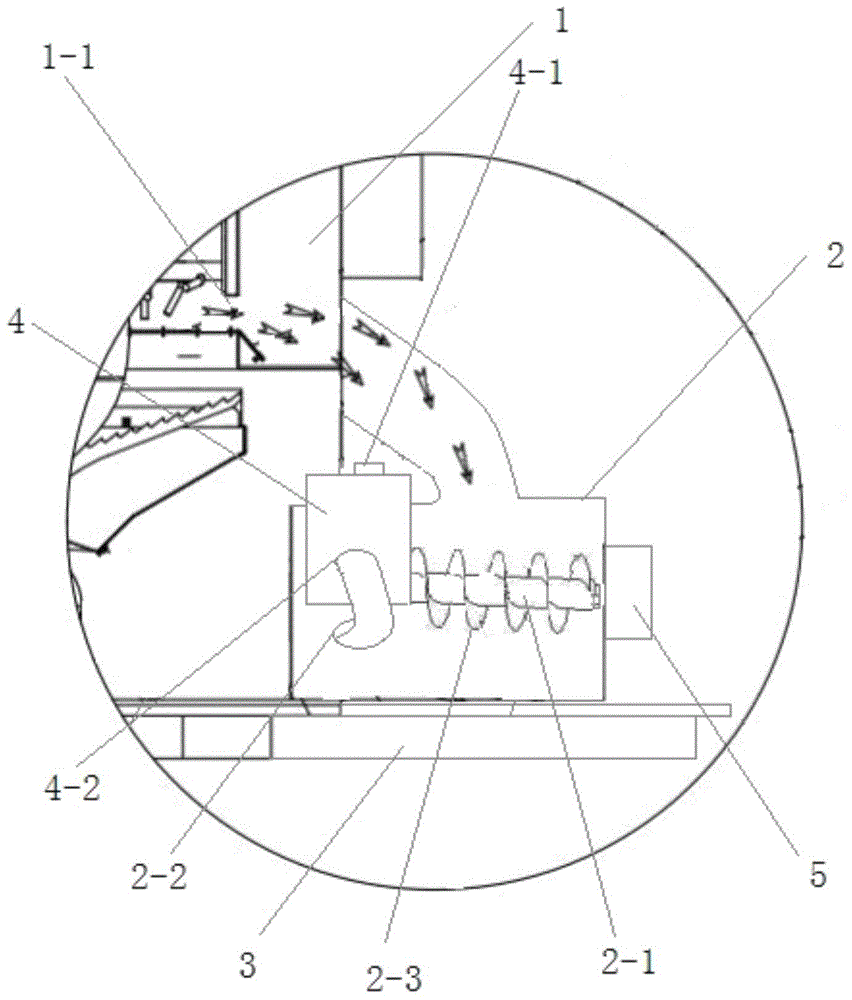

[0012] Such as Figure 1-2 Shown, a kind of dust-proof harvester comprises, comprises walking chassis, operating table, grain reel, cutter, conveyor chain, threshing mechanism and screening mechanism; Described threshing mechanism is made up of threshing drum 1 and concave plate sieve, The axial direction of the threshing cylinder 1 is parallel to the forward direction of the combine harvester; the grass outlet 1-1 of the threshing mechanism is located at the tail end of the threshing cylinder 1 shaft end; Below the tail end of the threshing drum 1 is installed a fixed grass-cutting blade, and the rotating grass-breaking blade and the fixed grass-breaking blade are arranged crosswise; a stirring chamber 2 is installed below the grass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com