Separating funnel for extraction and extraction instrument based on separating funnel

A separatory funnel and extraction technology, which is applied to laboratory containers, funnels, chemical instruments and methods, etc., can solve the problem that a small amount of solution is not easy to extract, and achieve the effect of safe processing and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

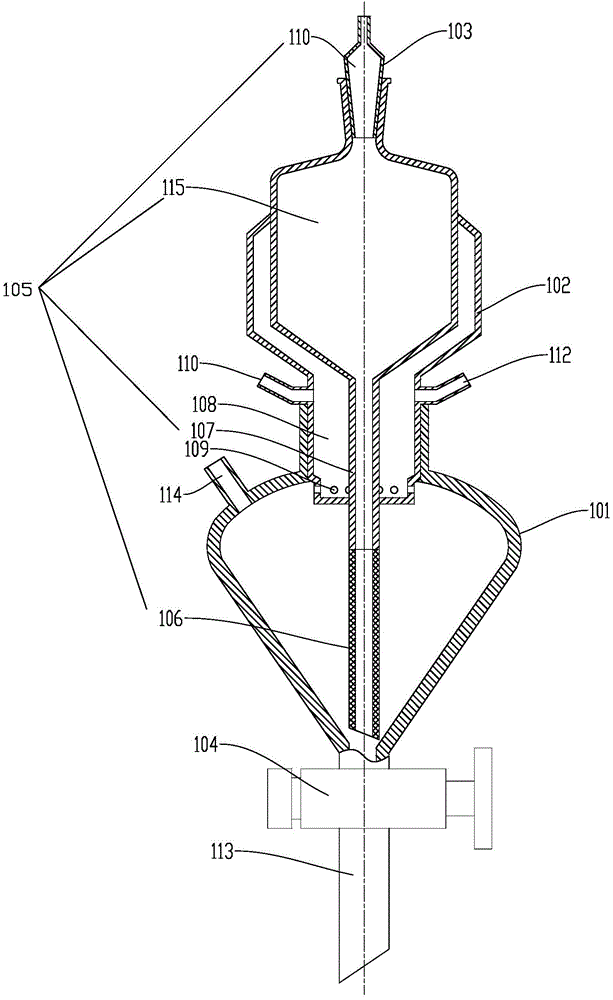

[0030] Such as figure 1 As shown, the separating funnel for extraction includes a bucket body 101, a bottle mouth is arranged on the top of the bucket body 101, a bottle stopper assembly is arranged on the bottleneck, and a vent pipe 105 is provided at the bottom end of the vent pipe 105. The air vent at the end is located at the inner bottom of the bucket body 101, and the top of the air pipe 105 is also an air vent, and the air vent at the top is located outside the bucket body 101; the bucket body 101 is also provided with another opening 114 for ventilation . If the ventilation pipe 105 takes air into the bucket, the opening 114 exhausts outward; if the ventilation pipe 105 sucks air outward, the opening 114 takes air into the bucket to keep the air pressure in the bucket.

[0031] As a further technical scheme of the separating funnel for this kind of extraction: the vent tube 105 is arranged in the bottle stopper assembly; and the vent tube 105 includes a small air guid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap