Screening method of parallel lithium ion batteries

A lithium-ion battery and screening method technology, applied in the field of screening of parallel lithium-ion batteries, can solve problems such as safety issues, battery cascading failures, failure of the entire battery pack, etc., to improve safety and reliability, and simple execution method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

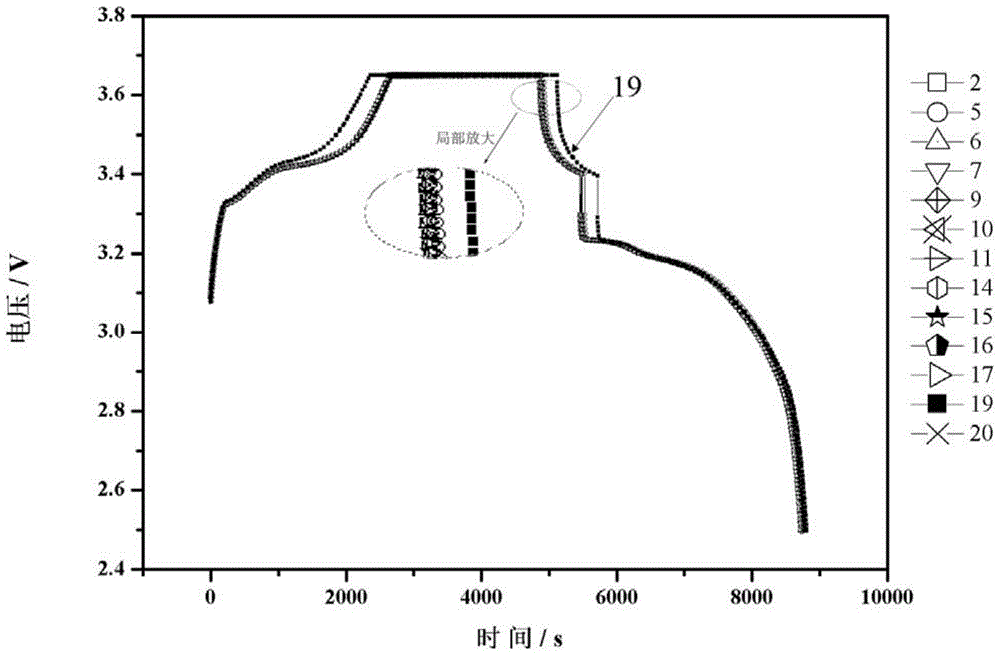

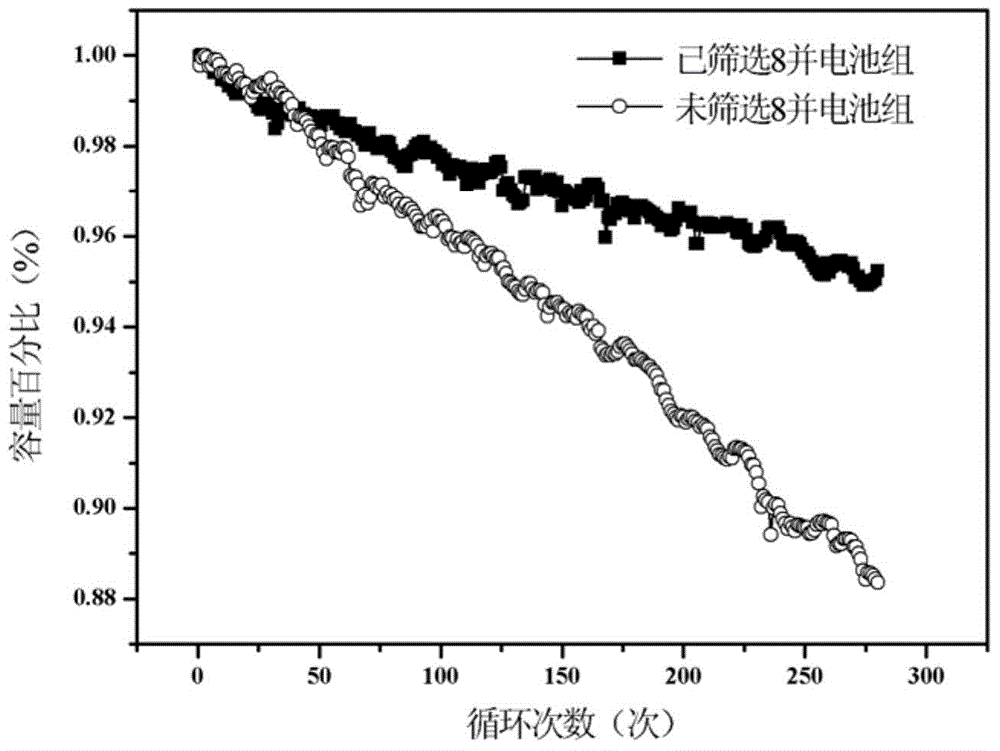

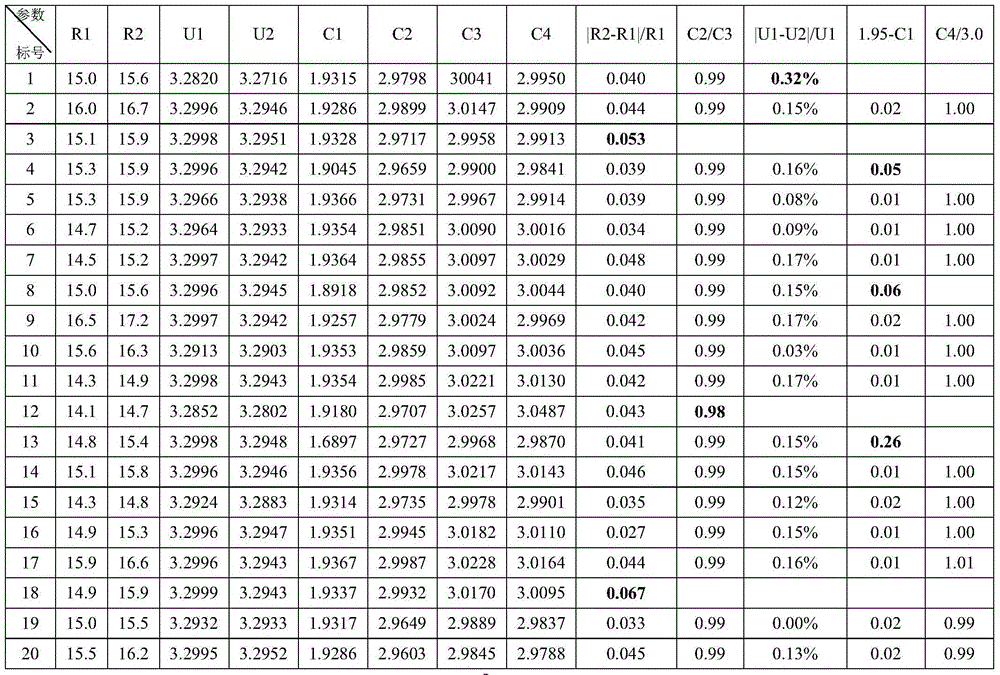

[0030] In this embodiment, the screening of 3Ah IFR26650 lithium-ion batteries is used as an example, and 20 single cells to be screened are taken from the same batch, and the following parameters are measured respectively:

[0031] (1) After the first charge-discharge cycle of the single cell, fully charge the single cell, and detect the internal resistance R1 of the battery;

[0032] (2) Discharge to the cut-off voltage, charge 65% of the capacity with a constant current, that is, 1.95Ah, and measure the voltage U1 of the single cell; after 15 to 20 days of storage, detect the voltage U2 of the single cell, discharge to the cut-off voltage, and record the discharge capacity C1;

[0033] (3) Fully charge the above-mentioned single cell again, record the capacity C2 at the end of constant current charging and the total charge capacity C3, and detect the internal resistance R2 of the battery; discharge to the cut-off voltage, and record the discharge capacity C4;

[0034] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com