High-diffusion-reflection glaze layer, stain-resistant glaze layer, and glaze composition for manufacturing them

A technology of glaze and manufacturing method, applied in the field of glaze composition, can solve the problems of surface concave and convex will be polluted or not, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0030] glaze composition

[0031] The glaze layer composition according to the first embodiment of the present invention includes glass frit containing zirconium element and zirconium silicate particles.

[0032] In the glass frit of this embodiment, ZrO 2 In conversion, it is a glass frit containing a zirconium element in an amount of 1.0% by mass to 15% by mass, preferably a glass frit containing a zirconium element in an amount of 1.2% by mass to 10% by mass. According to a preferred embodiment, the frit is a zircon opaque frit. In this embodiment, when the glass frit containing the above-mentioned amount of zirconium is fired, microcrystals of zirconium silicate can be precipitated in the glassy matrix. According to a preferred embodiment, the particle diameter of the microcrystals is more than 0 μm and less than 0.3 μm.

[0033] In the present embodiment, the zirconium silicate particles are particles having an average particle diameter of not less than 0.4 μm and not ...

no. 2 approach

[0047] Components of this embodiment

[0048] According to this embodiment, there is provided a member including a substrate and a glaze layer on the substrate, wherein the glaze layer is composed of at least a first glaze layer and a second glaze layer on the first glaze layer. Composition of the glaze layer.

[0049] first glaze layer

[0050] In this embodiment, the first glaze layer contains white inorganic oxide particles and a vitreous component. The inorganic oxide particles contain Al and / or Zr, have a refractive index exceeding 1.7 and not more than 2.5, and have an average particle diameter of 0.4 μm. Above 5 μm and below.

[0051] In the first glaze layer, the white inorganic oxide particles are preferably at least one selected from the group consisting of zirconium silicate (refractive index 2), zirconia (refractive index 2.4), and alumina (refractive index 1.76). kind. These components have a higher refractive index than the vitreous component, and since parti...

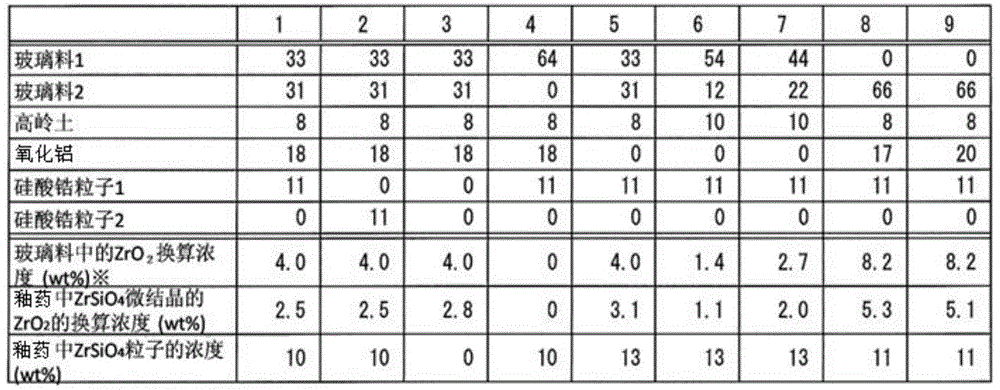

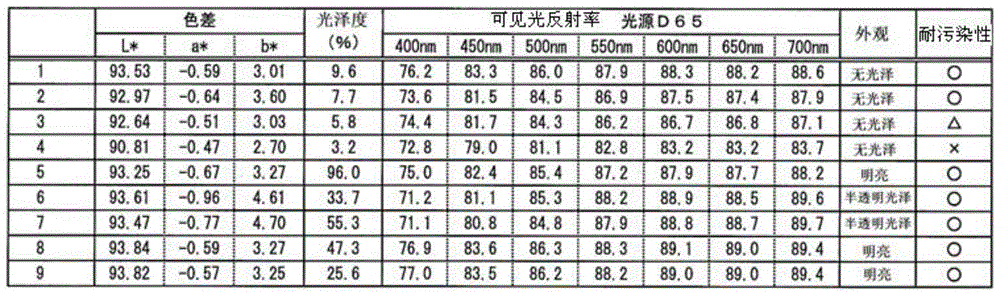

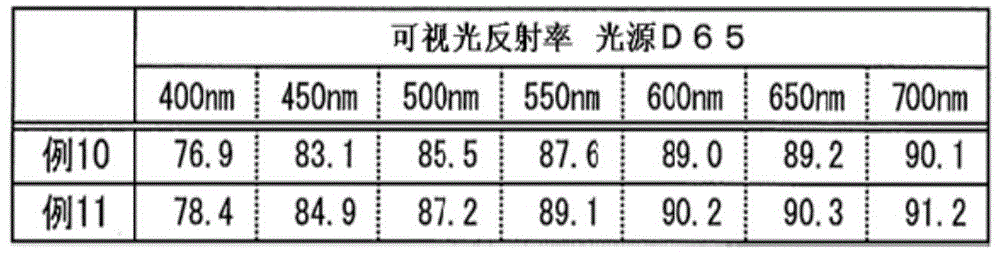

Embodiment 1~9

[0098] Preparation of base material

[0099] After mixing dry powder composed of 50% wollastonite, 40% clay and 10% talc, water is added to prepare a plastic adobe. The adobe was shaped and rolled by an extruder to form a plain flat plate with a width of 600 mm, a length of 900 mm, and a thickness of 4 mm. After the plain slabs are dried, they are fired in a roller kiln at a maximum temperature of 1150°C.

[0100] Preparation of the first glaze composition

[0101] 40 parts by mass of feldspar, 15 parts by mass of kaolin, 15 parts by mass of zirconium silicate particles, and 30 parts by mass of glass frit mixed with zirconia particles are mixed with 40 parts by mass of water and pulverized with a grinder After 20 minutes, prepare the first glaze composition in the form of a slurry. The average particle diameter of the zirconium silicate particles used here is 0.8 μm.

[0102] Second glaze composition

[0103] Glass frits 1 and 2 having the compositions described in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com