Double eccentric crank thread anti-loosening device

A double-eccentric, threaded technology, applied in the direction of threaded fasteners, screws, nuts, etc., can solve the problems of loosening, low reliability of nut pads, difficult processing, etc., to prevent the loosening of threads, good anti-loose effect, Implement easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

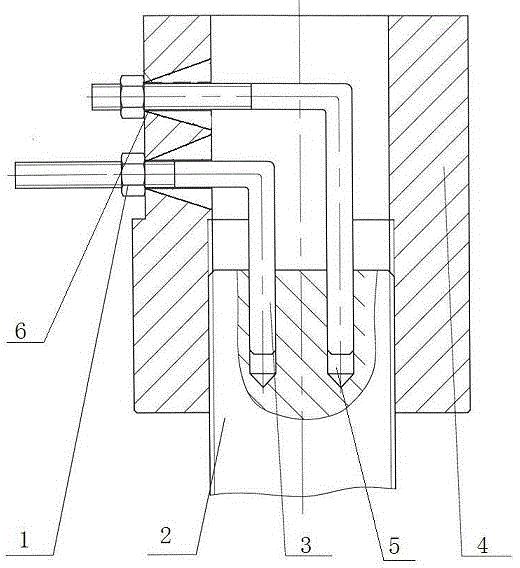

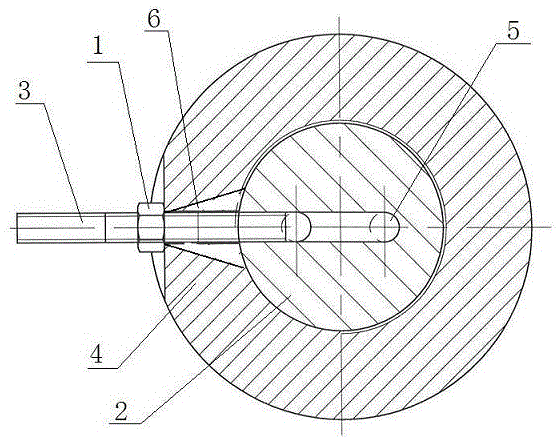

[0016] Such as figure 1 , 2 The shown double eccentric crank thread anti-loosening device includes a threaded screw 2, on which a nut 4 matched with the threaded screw 2 is sleeved, and a crank 3, one end of the crank 3 is provided with a thread, and the side of the nut 4 is A tapered hole 6 is provided on the top, the surface of the small diameter of the tapered hole 6 is located on the same surface as the outer surface of the nut 4, and the top end surface of the threaded screw 2 is provided with an eccentric hole 5;

[0017] The threaded end of the crank 3 extends through the tapered hole 6 to the outside of the nut 4 and is locked by the locking nut 1 , and the other end of the crank 3 is inserted into the eccentric hole 5 .

[0018] When the nut 4 and the threaded screw 2 are tightened, the crank 3 goes deep into the nut 4 from the tapered hole 6, and is inserted into the eccentric hole 5, and then locked with the lock nut 1, the crank 3 reaches the nut lock. For the pu...

Embodiment 2

[0020] In the above example, if figure 1 , 2 The double eccentric crank thread anti-loosening device has two cranks 3, two locking nuts 1 fitted on the cranks 3, and two corresponding tapered holes 6 and eccentric holes 5 on the side of the nut 4. The eccentric hole 5 is arranged symmetrically on both sides of the center line of the screw rod 2, the tapered hole 6 is on the same generatrix of the nut 4, one end of the two cranks 3 is put into the tapered hole 6, and the other end is put into the eccentric hole 5 Among them, when the nut 4 rotates in place, use the lock nut 1 to lock and lock it, and the crank 3 can achieve the purpose of the nut 4 from rotating. Using two cranks 3 and symmetrical eccentric holes 5 can better align the nut 4 with the thread Screw rod 2 is locked after being tightened. When the two cranks 3 are arranged symmetrically, the threaded side of one crank 3 will always retract along the tapered hole 6, and its retraction is restrained by locking the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com