Comb tooth shaped elasticity self-adaptive sealing structure

An adaptive sealing and elastic technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., to achieve the effect of good versatility, simple installation and good sealing performance

Inactive Publication Date: 2014-09-03

JINAN FAN FACTORY CO LTD

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Aiming at the deficiencies of the prior art, the present invention provides a comb-tooth elastic self-adaptive seal, which is used to solve the dynamic sealing problem between the rotating part and the stationary casing which is common in equipment such as centrifugal fans

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

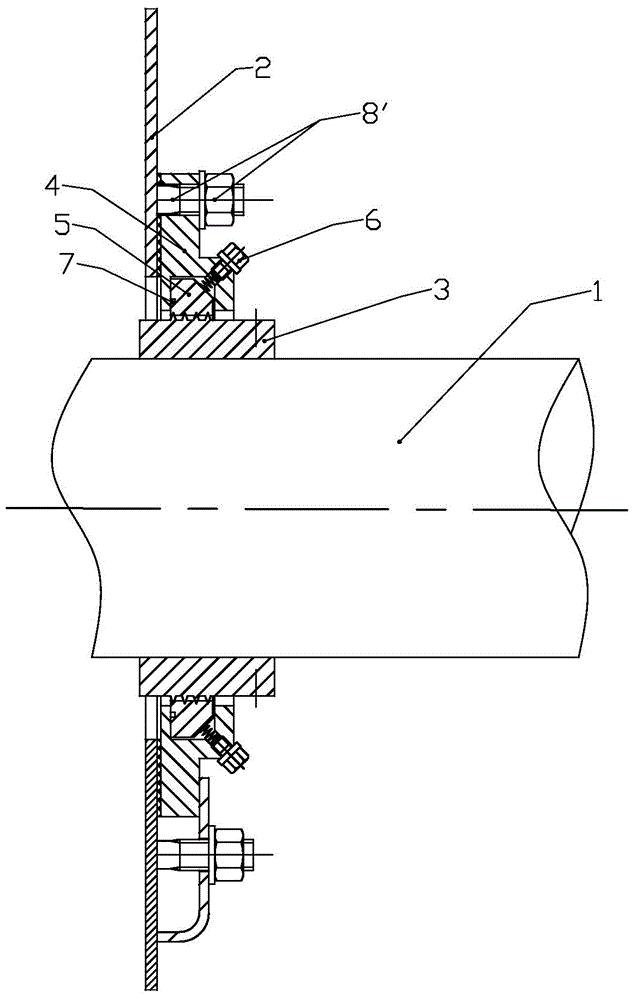

[0037] Embodiment two, such as image 3 , The difference from Embodiment 1 is that the pressing device 8' is a bolt fastener that can be directly fixed on the housing, which can realize direct fixing, and the number is also 4 groups.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

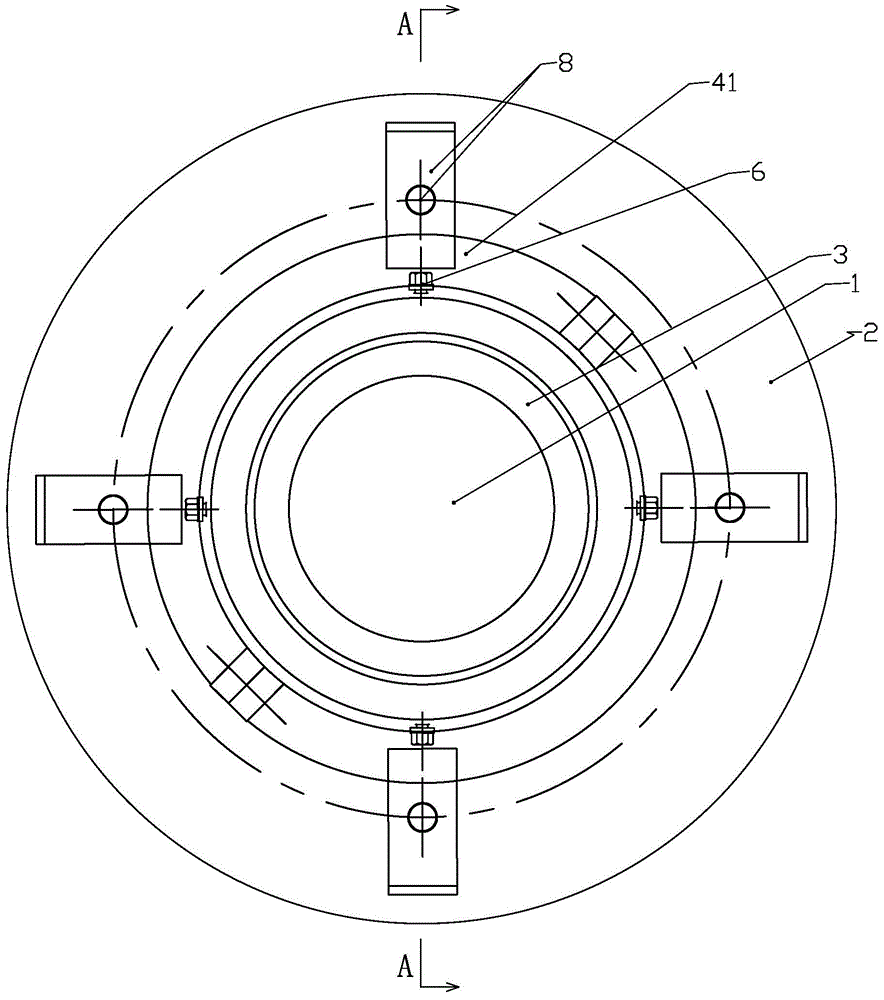

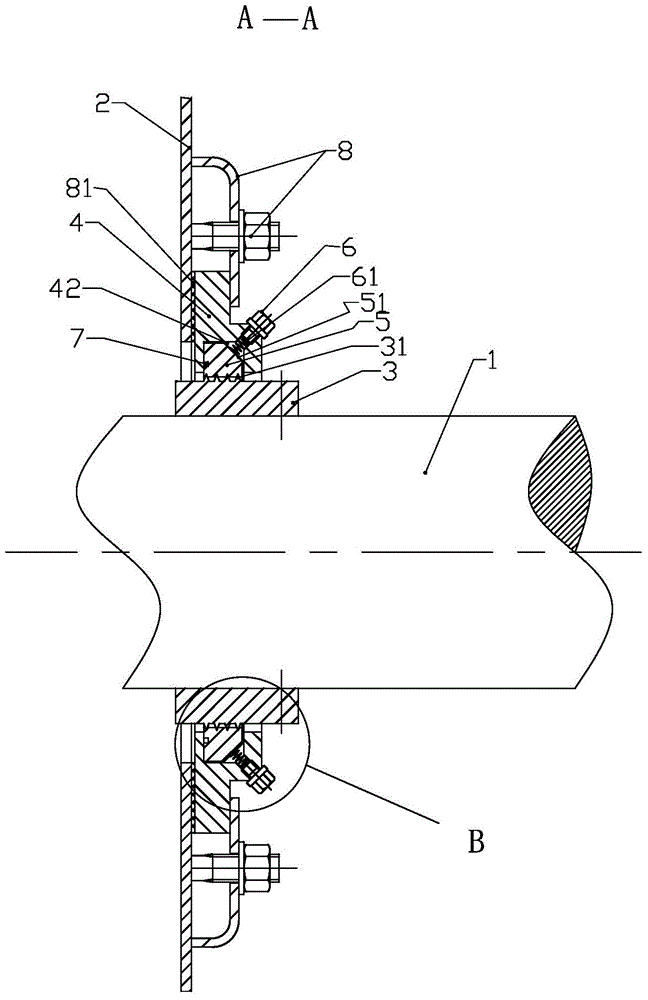

The invention discloses a comb tooth shaped elasticity self-adaptive sealing structure, which comprises a rotating shaft, a shell as well as a shaft bush and an annular sealing disc which are arranged between the rotating shaft and the shell, wherein the shaft bush is sleeved with the annular sealing disc; a sealing cavity is formed in the inner wall, towards the shaft bush, of the sealing disc; a wearable sealing ring is filled in the sealing cavity; multiple sealing plugs and spring elements are arranged between the wearable sealing ring and the sealing disc; the wearable sealing ring and the shaft bush are kept in contact through an oblique thrust by virtue of the sealing plugs and the spring elements; a packing is arranged between the wearable sealing ring and the rear wall of the sealing cavity; and the sealing disc is tightly pressed and fixed on a casing through a pressing device, and at least one rubber sealing washer is arranged at the attaching surface between the sealing disc and the shell. The comb tooth shaped elasticity self-adaptive sealing structure is good in sealing performance; the effect of the sealing structure can be compounded with those of a labyrinth type seal and a wearable seal; and besides, the sealing structure is compact, convenient to machine and assemble, good in universality and wide in application scope, and needs no modification of an original shaft structure.

Description

technical field [0001] The invention relates to a comb-tooth elastic self-adaptive seal, which is a seal used between a rotating part and a stationary casing, especially a seal structure used by a centrifugal fan. Background technique [0002] With the increasingly prominent environmental and energy issues, the government has made great efforts to rectify the pollution links of various polluting enterprises. As the main power equipment of dust removal, desulfurization, denitrification and other equipment, the role of centrifugal fans should not be underestimated. However, the centrifugal fan is usually sealed with simple seal or asbestos packing, and the effect can be imagined. Therefore, the problem of external leakage of centrifugal fans is relatively serious. External leakage not only reduces the overall efficiency of the fan, but also may cause the leakage of dust gas or even toxic, harmful and irritating gases, causing serious harm to humans and the environment. There ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16J15/16F16J15/447

Inventor 郝德华杨斌刘宝星张玉亮徐志林

Owner JINAN FAN FACTORY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com