An outer diameter detection device

A technology of a detection device and a detection mechanism, which is applied to measurement devices, instruments, etc., can solve the problems of inaccurate detection, inconvenient manual detection methods, and inability to use normally, and achieve the effects of convenient use, easy detection, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

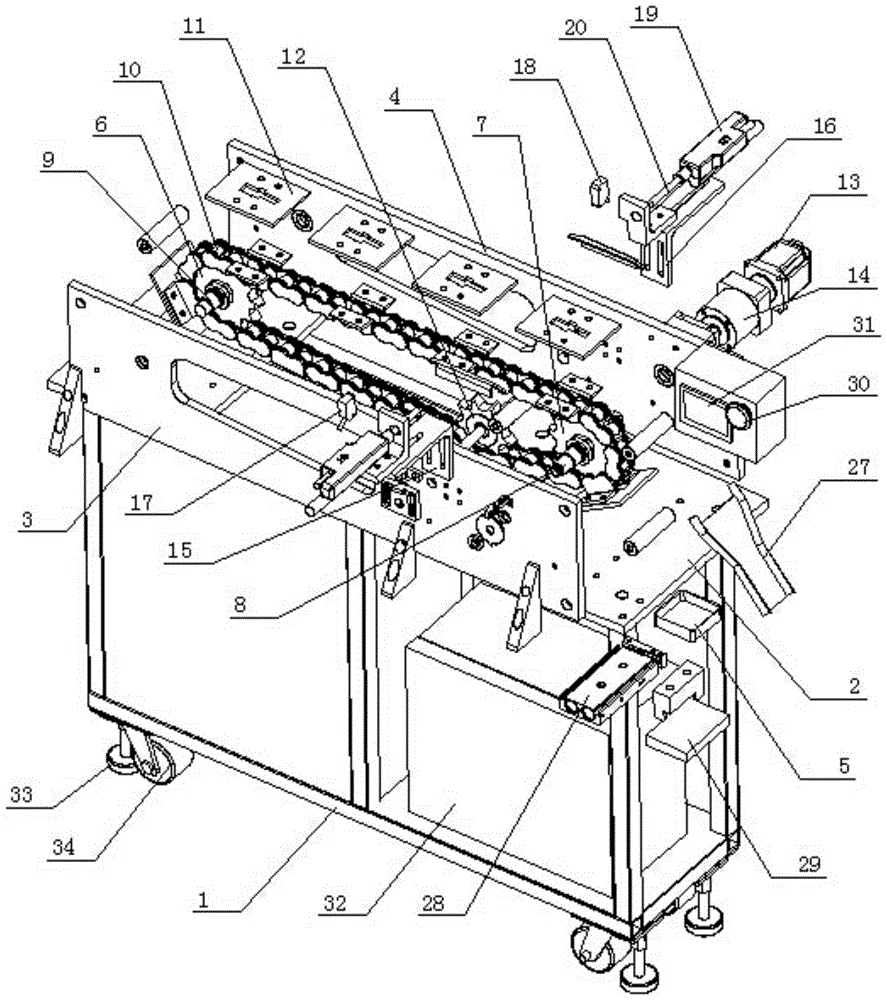

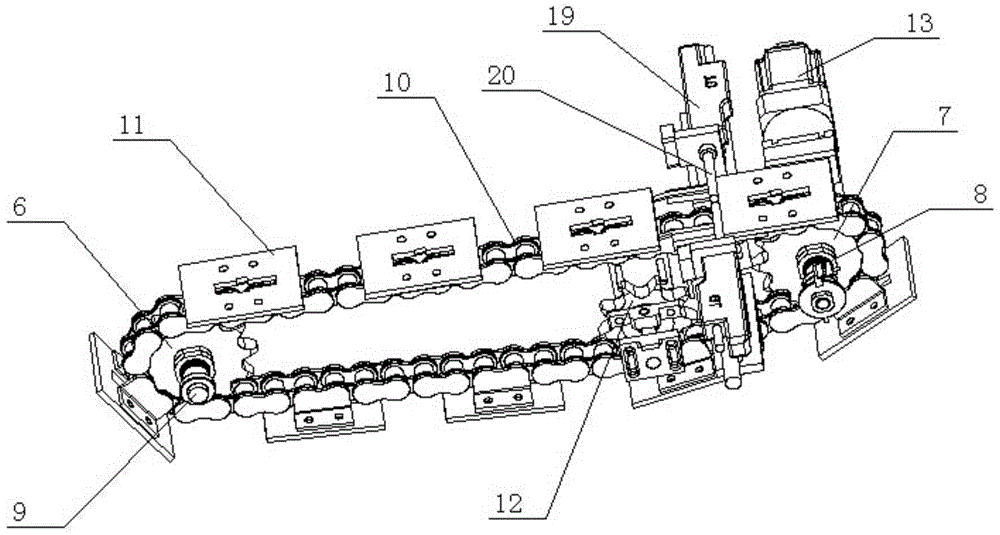

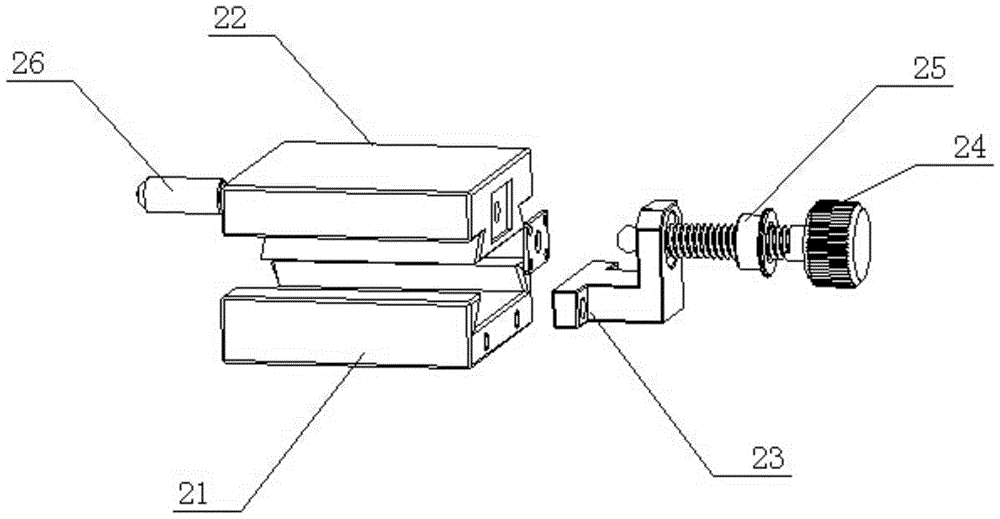

[0027] Embodiment one: see Figures 1 to 3 As shown, a kind of outer diameter detection device, comprises device frame body 1, and described frame body 1 lower end is provided with leg 33 and pulley 34 around respectively, and described frame body 1 is provided with working platform 2, and described working platform 2 The first and second guard plates 3 and 4 are respectively arranged on both sides, and a transmission mechanism is arranged between the two guard plates on the working platform 2, and the transmission mechanism is driven by a driving mechanism arranged on the outside of the second guard plate 4 Near the end of the transmission direction of the transmission mechanism, an outer diameter detection mechanism is respectively provided on the outside of the two guard plates, and a collection box 5 is arranged below the end of the transmission direction of the transmission mechanism, which is connected with the transmission mechanism A micro-adjustment mechanism is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com