Device for measuring an internal or external profile of a tubular component

A measuring device and measuring tube technology, applied in the direction of measuring devices, electromagnetic measuring devices, optical devices, etc., can solve the problems that are not suitable for fast and effective measurement, and achieve the effect of increased accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

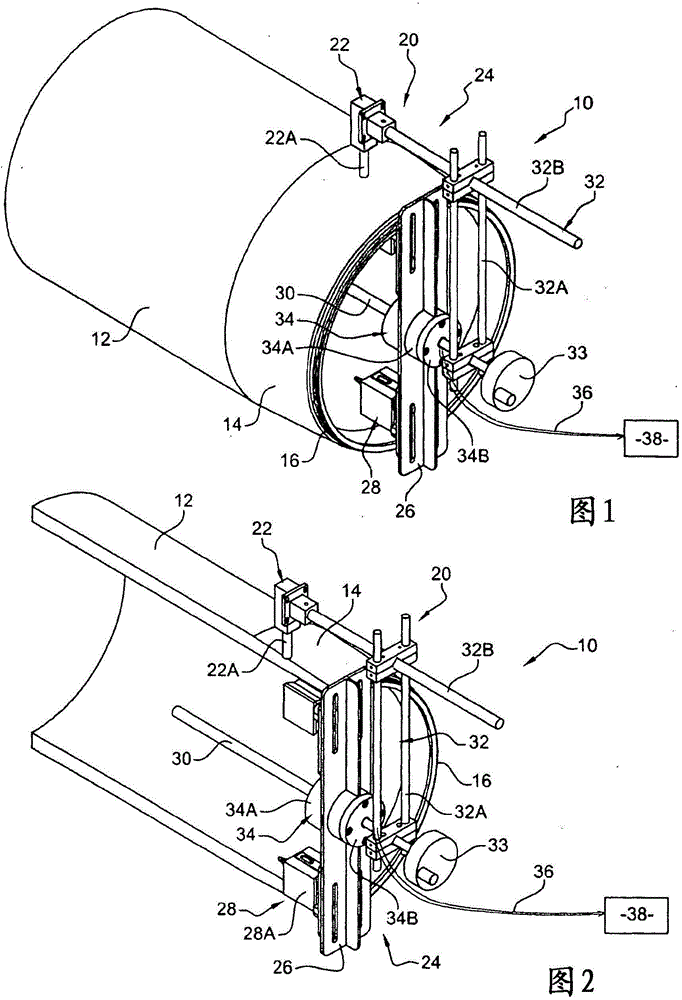

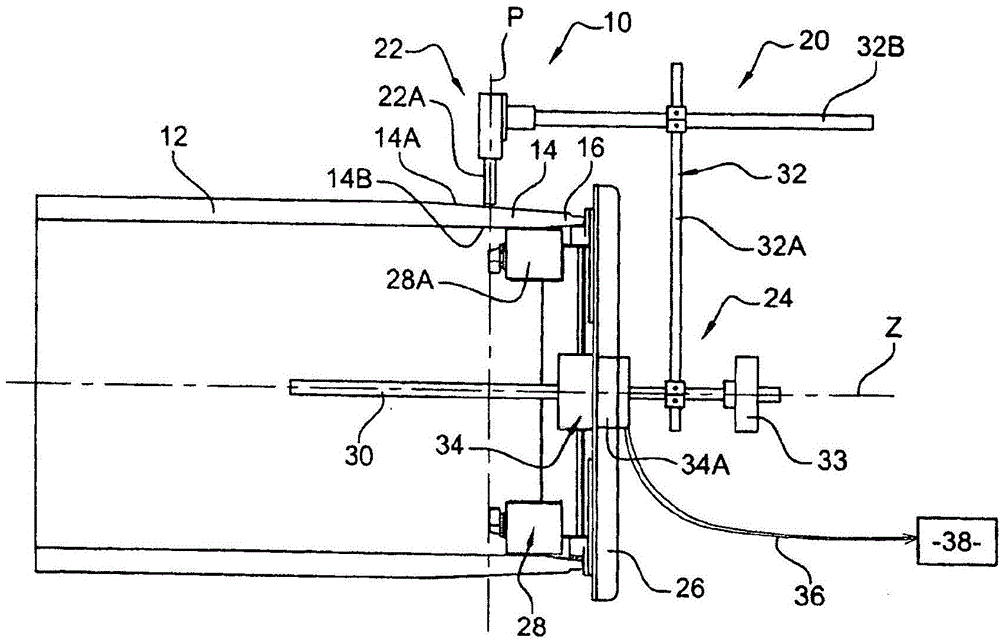

[0036] exist Figure 1 to Figure 4 The above shows the control equipment of the tubular member. This device is indicated by reference number 10 .

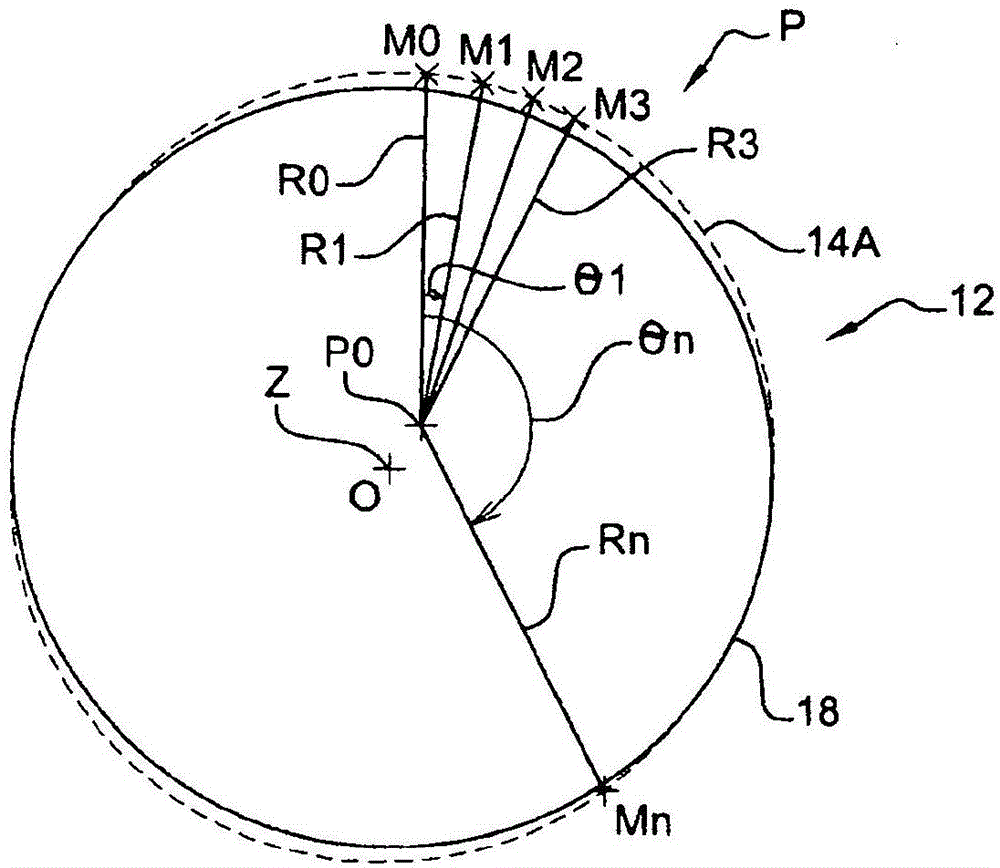

[0037] In the example described, the device 10 is used to control a tubular member 12 comprising an end portion 14 having an outer profile 14A and an inner profile 14B. The end portion 14 of the member 12 is generally threaded to allow a screwed coupling with another tubular member (not shown). In the example shown by the figures, the tubular member 12 includes a male end 16 . The tubular member typically has a length of several meters. The tubular member 12 comprises a body that revolves around a major axis Z ( image 3 ). The inner profile 14B (or outer profile 14A) of the component 12 is defined as the profile of the component 12 , ie the inner profile (or outer profile) of the component around the axis Z of the component 12 . Ideally, the inner profile 14B or outer profile 14A of the component 12 in a plane normal to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com