Screw rod cleaning equipment

A technology for cleaning equipment and screws, applied in the field of cleaners, can solve the problems of inconvenient use of labor, corrosion of human hands by screw cleaners, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

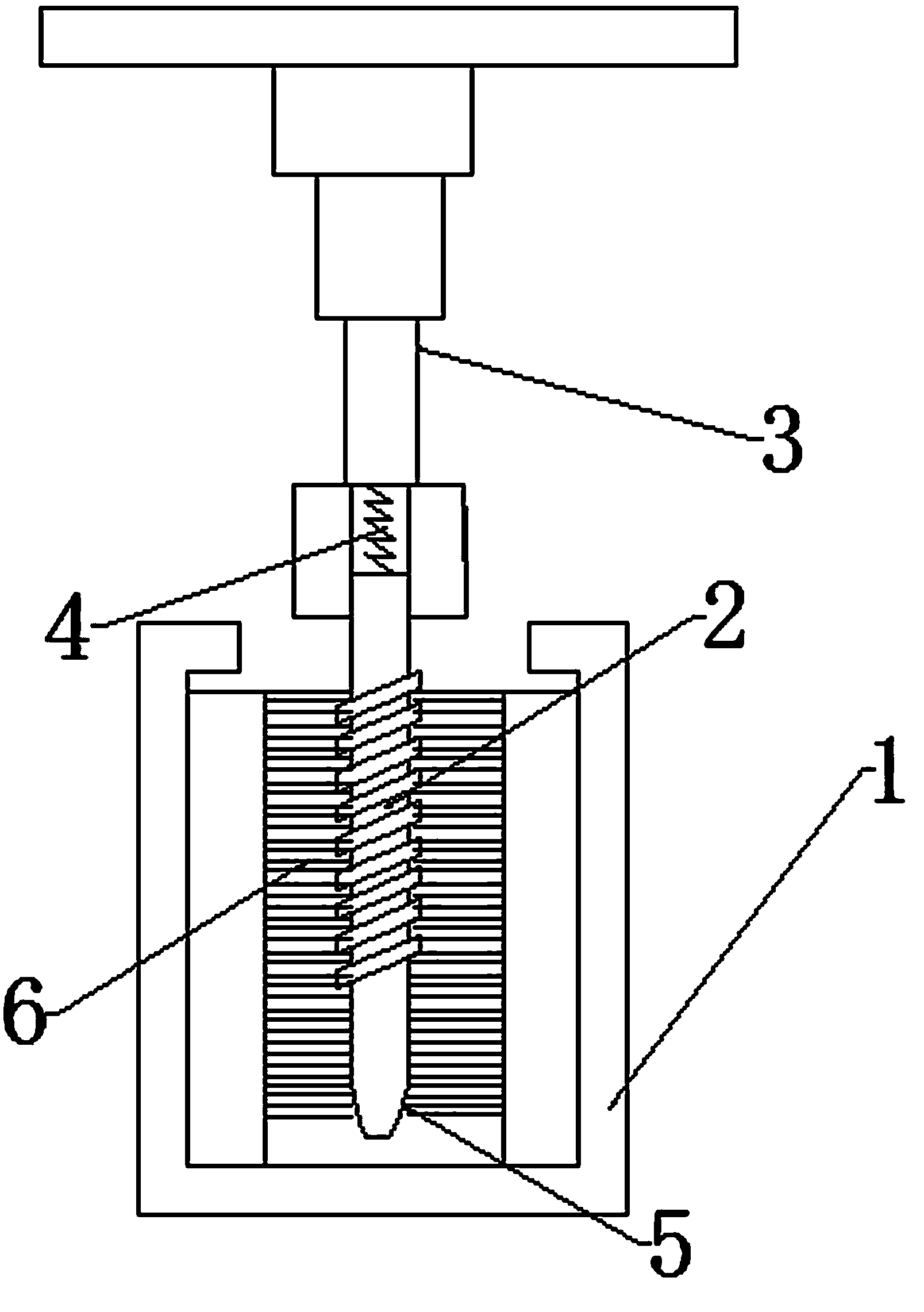

[0018] A screw cleaning device, comprising: a moving part connected to the screw 2 and driving the screw 2 to move up and down, a cleaning tank 1 containing clean water, and a brush 6 placed in the cleaning tank 1 and capable of wrapping the screw 2; as a preference, the brush 6 is an annular brush 6, which wraps the screw rod 2 and contacts every place of the screw rod 2. A placement cavity 5 for accommodating the screw rod 2 is provided between the brushes 6 ; in order to allow the brush 6 to fully contact every corner of the screw rod 2 , the diameter of the placement cavity 5 is smaller than that of the screw rod 2 . As a preference, the moving part is a telescopic rod 3; in order to save manpower and can bear the weight of the screw rod 2, the telescopic rod 3 is an electric stainless steel telescopic rod 3. The screw rod 2 is verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com