Molding device and blowing-filling-sealing integrated machine with the same

A molding device and the same technology, applied in the fields of medical packaging machinery and food, can solve the problems of difficulty in ensuring the accuracy of mold clamping, large space occupation, and difficulty in debugging, and achieve the effects of small space occupation, simple and compact structure, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

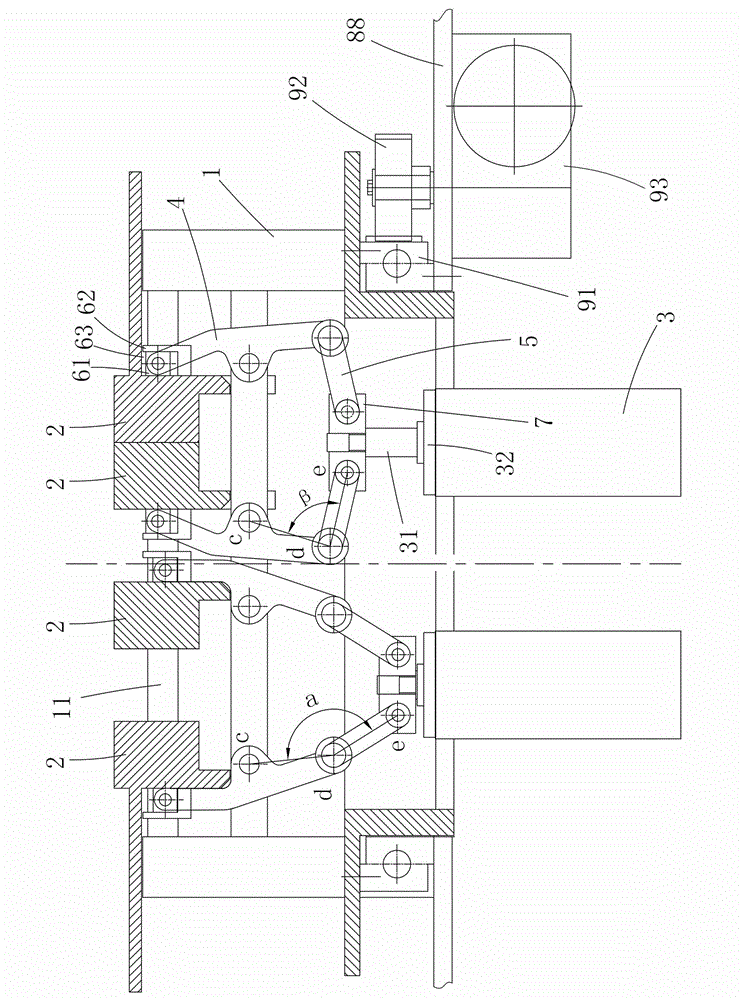

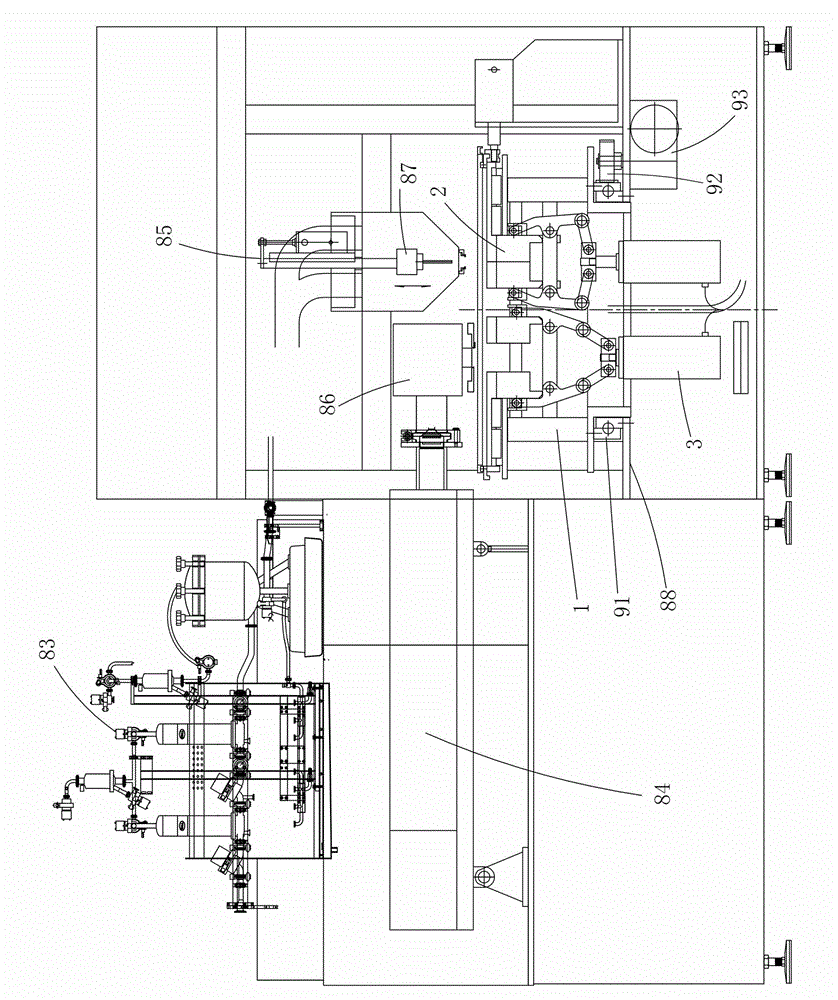

[0022] Such as figure 1 As shown, the molding device of the present invention is applied to a blow-fill-sealing integrated machine as an example. It includes a support 1 and two sets of main molds mounted on the support 1, wherein the left main mold is in an open state, and the right The main mold on the side is closed. Each set of main molds includes two main mold halves 2 installed on the support 1 and movable on the support 1 in an opposite manner, and a mold clamping mechanism for driving the two main mold halves 2 to open and close. In this embodiment, the two main mold halves 2 are slidably arranged on the sliding rod 11 of the support 1, and the sliding rod 11 is arranged horizontally. The clamping mechanism includes a drive cylinder 3 and two sets of connecting rods connected to the drive end of the drive cylinder 3. The expansion and contra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap