Hydraulic retarder with locking device and control oil path, capable of eliminating windage loss

A hydraulic retarder and locking device technology, applied in the direction of brakes, brake types, hydraulic resistance brakes, etc., can solve the problems of increasing the axial length of the hydraulic retarder, difficult layout of other components, and complicated operating mechanism, etc., to achieve Eliminate blowing loss, simple structure, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] The present invention will be described in detail below in conjunction with the drawings.

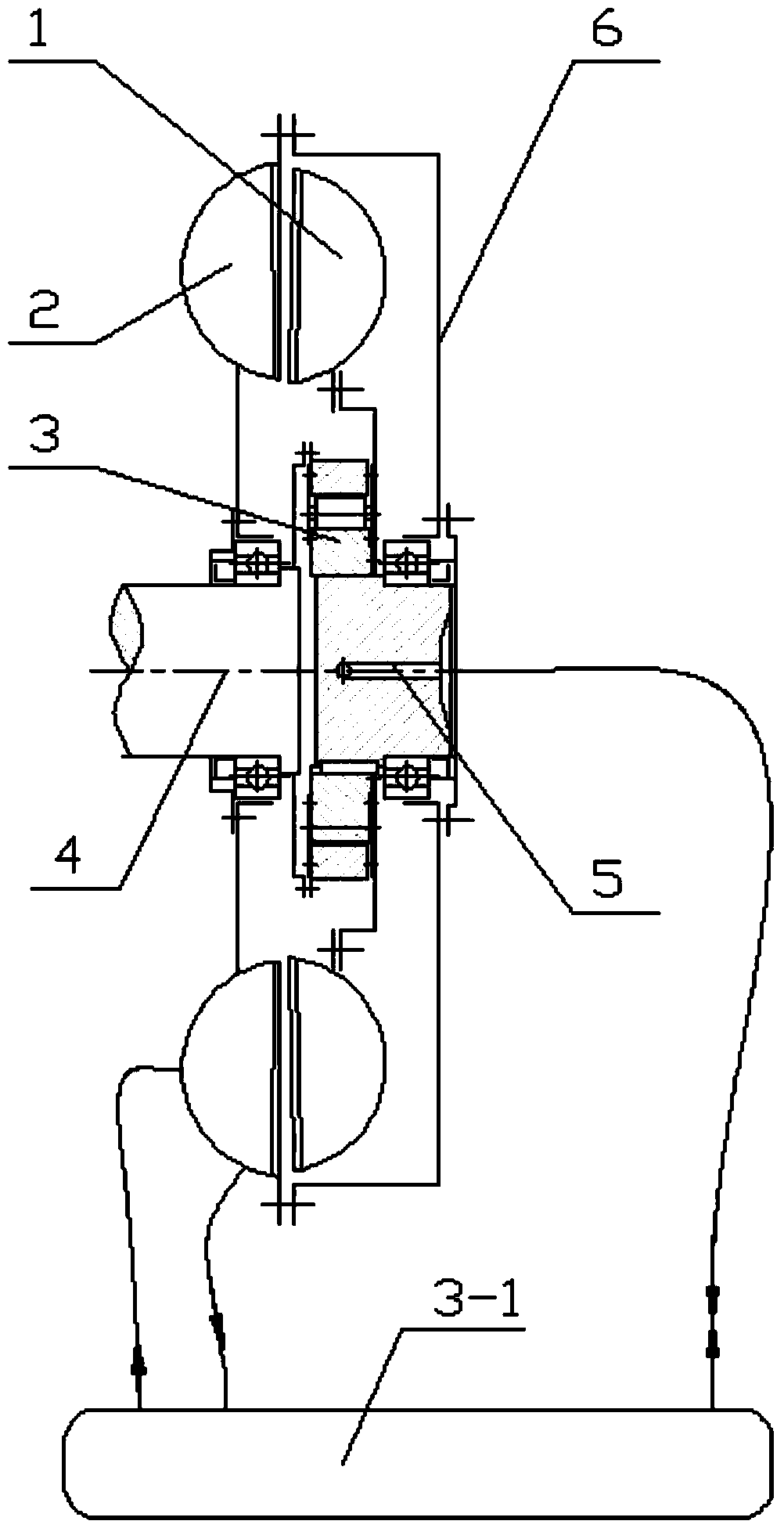

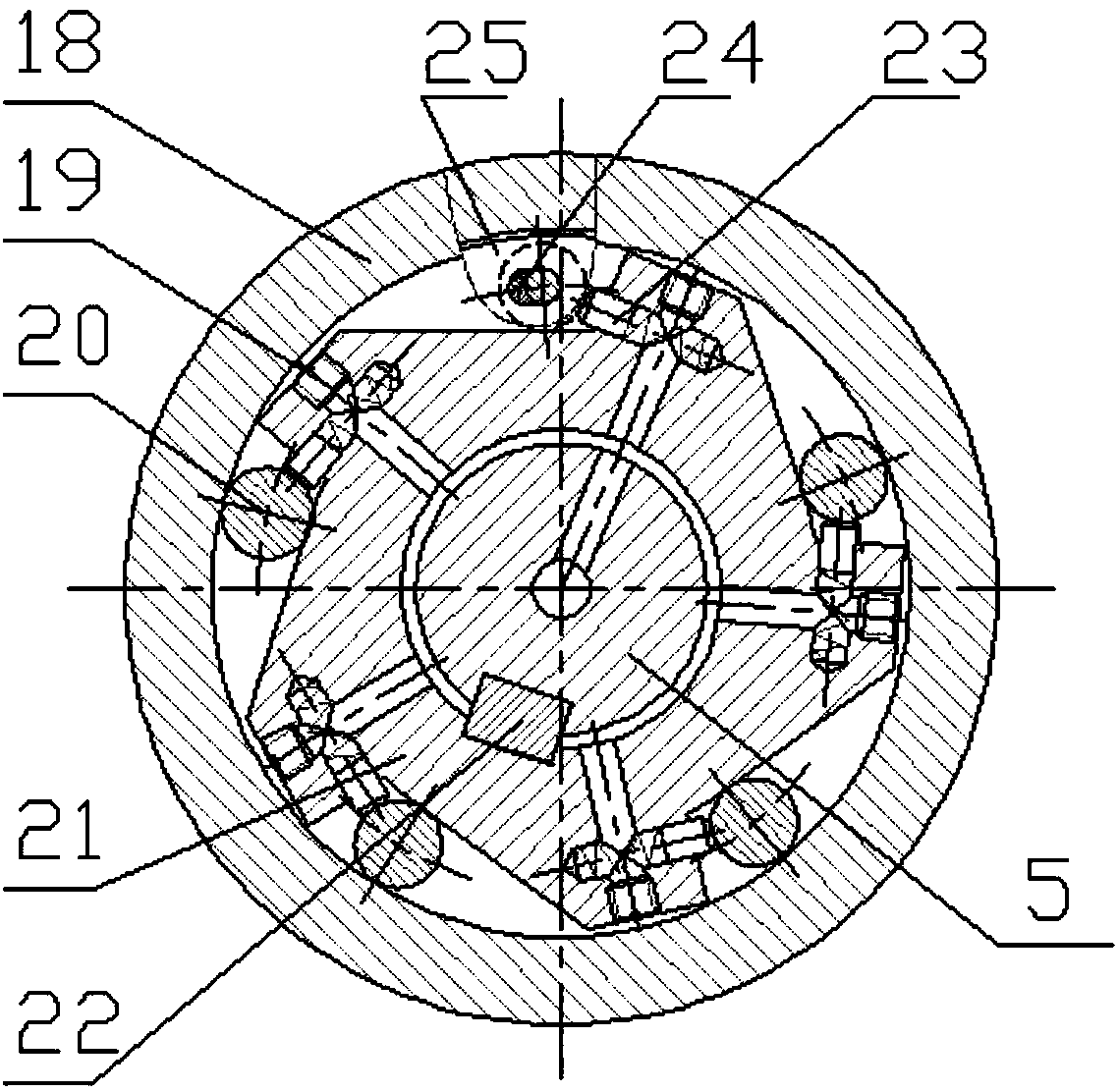

[0036] Such as figure 1 As shown, a hydraulic retarder with a locking device and control oil circuit of the present invention that can eliminate blast loss mainly includes a locking device 3, an input half shaft 4 fixedly connected to the outer ring 18 of the locking device 3, The brake half shaft 5, which is fixedly connected to the inner ring 21 of the locking device 3, is mounted on the stator 2 of the input half shaft 4 through a bearing, and is fixedly connected to the rotor 1 of the brake half shaft 5, and is smooth with the oil inlet passage of the locking device 3 The control oil circuit system 3-1 connected with the oil inlet and outlet ports of the speeder stator 2 and the casing 6;

[0037] The outer flange of the casing 6 is fixedly connected with the outer flange of the stator 2, and the inner ring part of the outer casing 6 is mounted on the brake axle 5 through a bearin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap