A Hydraulic Retarder with Friction Lock and Control Oil Circuit to Eliminate Blast Loss

A hydraulic retarder and blower loss technology, applied in the direction of brakes, clutches, braking components, etc., can solve the problem of increasing the axial length of the hydraulic retarder, unreliable retarder work, and increased layout of other components, etc. problem, to achieve the effect of eliminating blowing loss, simple structure, and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

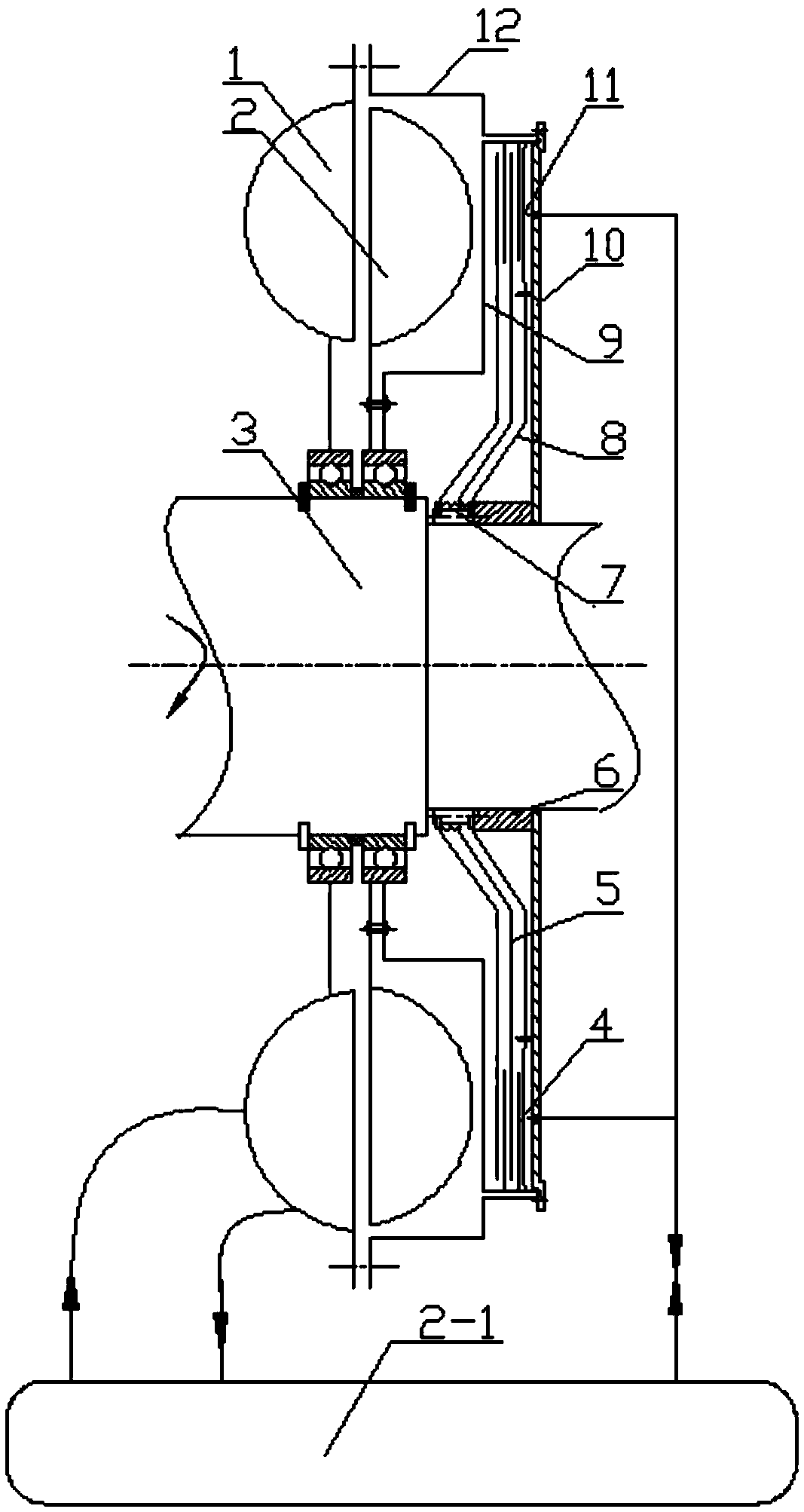

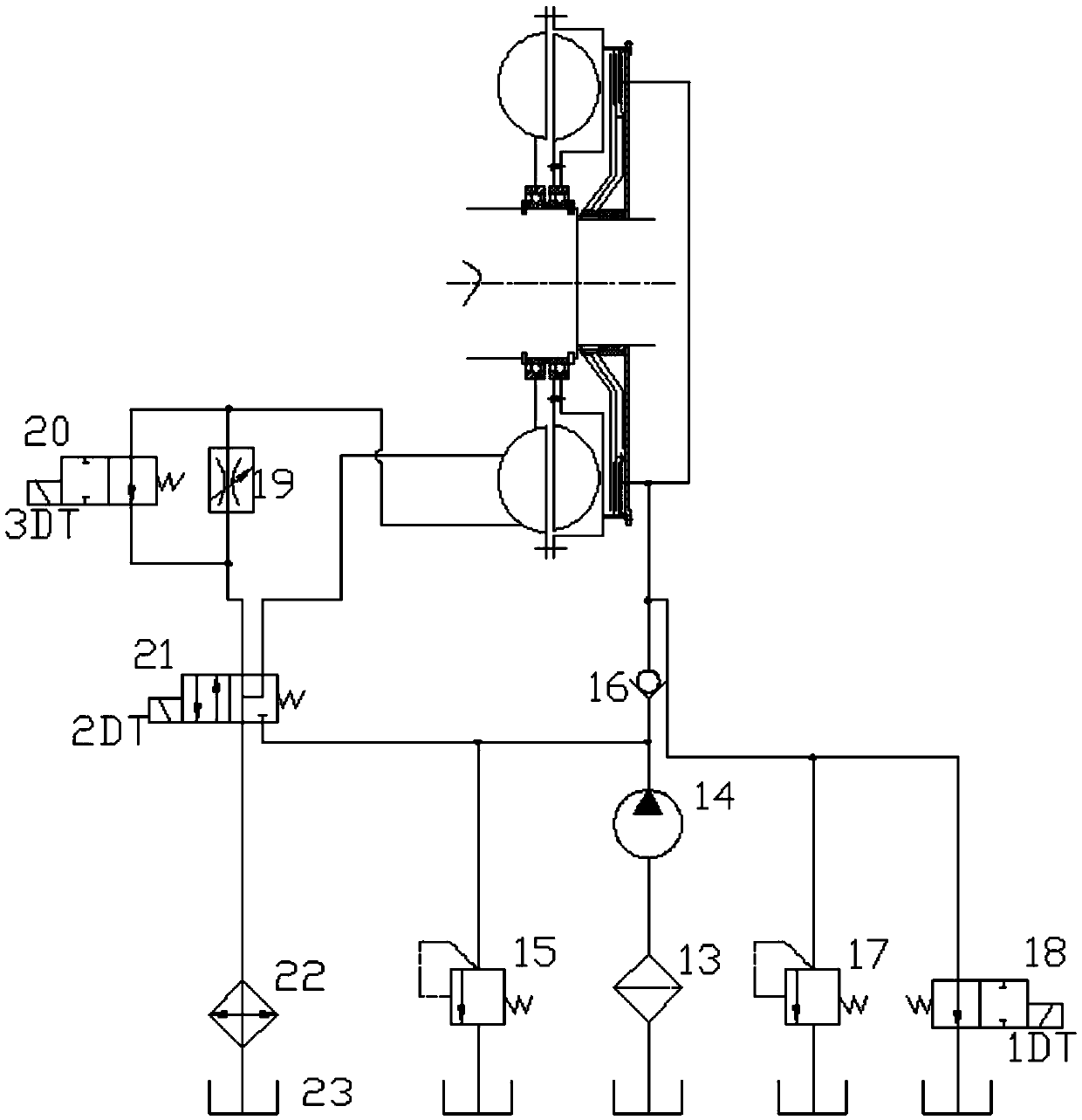

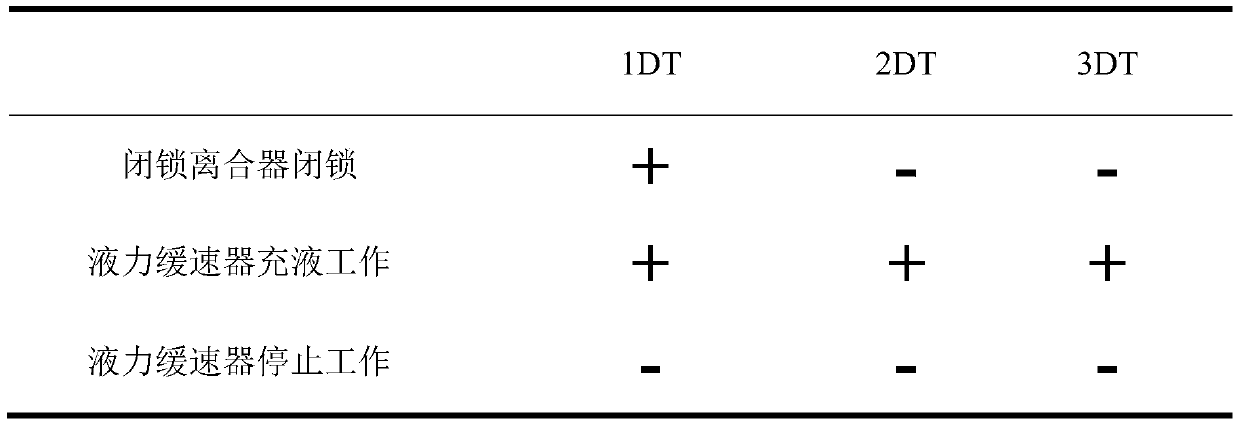

[0036] figure 1 It is a schematic diagram of the overall structure of the present invention. It can be seen that a hydraulic retarder with friction lock and control oil circuit in the present invention that can eliminate blowing loss mainly includes an input shaft 3, which is installed on the input shaft 3 through a bearing Stator 1 and rotor 2, the stator 1 is fixed on the housing 12 by bolts; the spline sleeve 9 is fixedly connected to the rotor 2 by rivets and installed on the input shaft 3 by bearings; the spline sleeve 9 is directly connected to the input shaft 3 by splines The active friction plate 5 of the lock-up clutch can slide on the spline shaft; the driven friction plate 4 directly connected to the spline sleeve 9 through the spline can slide on the spline sleeve 9; The end cover 10 fixedly connected by the inner flange; the piston support 8 fixedly con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap