Method and device for increasing adhesion force between wheel and rail of rail vehicle

A rail vehicle and adhesion technology, which is applied in the field of rail vehicles, can solve the problems of affecting the full use and exertion of traction force, accelerating the wear of wheel and rail, and poor use effect, so as to increase the adhesion traction force between the wheel set of rail vehicles and the rail, and increase the adhesion coefficient, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

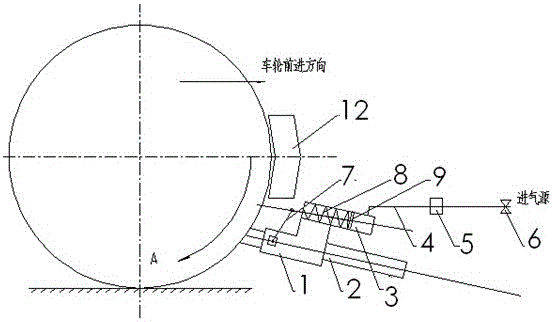

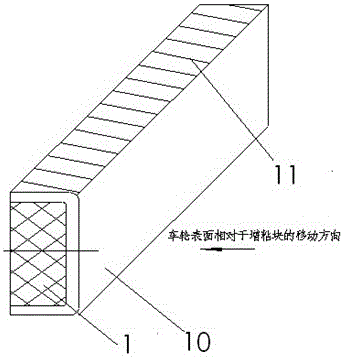

[0044] A method for increasing the adhesion between wheel and rail of a railway locomotive. When the locomotive pulls a train running on the rails, if the wheels of the locomotive tend to run idling (there are facilities for detecting idling on the train, it can be detected, and the driver on the locomotive can also pass Instrument finds), can automatically open or manually open the air valve 6 that is contained in the driver's compartment, and air valve 6 can be manually operated, as manual or foot, also can be electric automatic opening or closing. After air valve 6 is opened, the compressed air on the locomotive enters transmission cylinder 3 rapidly through pipeline 4 and pressure regulating valve 5, and pressure regulating valve 5 is according to the softness of thickening block, hard and the actual needs of locomotive to adjust pressure. After the compressed air enters the transmission cylinder 3, it pushes the piston 9 in the cylinder to move to the left, and the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com