Friction material, friction body, cleaning tile comprising friction body, and preparation method and application of cleaning tile

A friction material and raw material technology, applied in chemical instruments and methods, vehicle cleaning, transportation and packaging, etc., can solve problems such as inability to effectively eliminate wheel tread defects, low adhesion coefficient between wheel tread and rail, idling and slipping, etc., to achieve Effects of eliminating defects, increasing tread roughness, preventing idling and slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

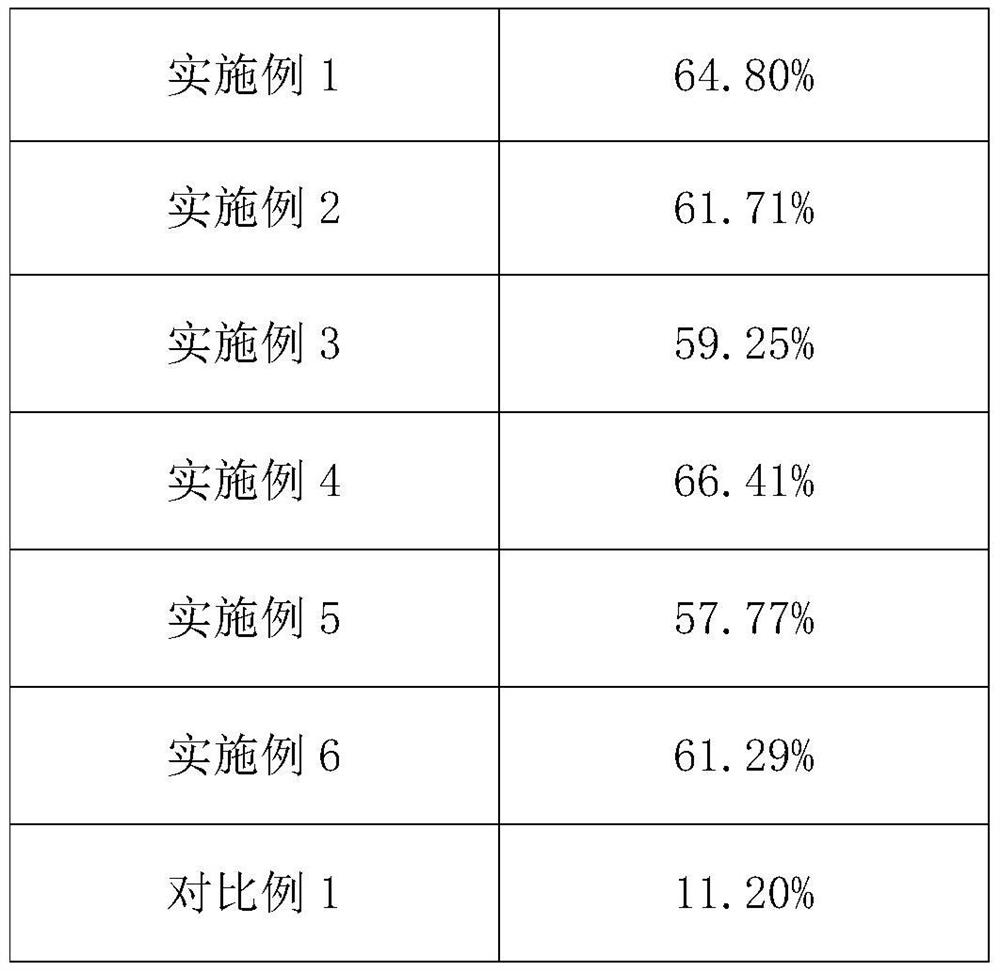

Examples

Embodiment 1

[0045]The present embodiment provides a friction material, including the following raw materials: 12g of binder, 20g of metal fiber, 10g of non-metallic fiber, 48g of tackifier, 6g of elastic particles, and 6g of lubricant; the binder is modified by nitrile Phenolic resin, boron modified phenolic resin, liquid cashew nut shell oil modified phenolic resin form, the mass ratio of described nitrile modified phenolic resin, boron modified phenolic resin, liquid cashew nut shell oil modified phenolic resin is 3:2: 2; the metal fiber is composed of steel fiber and brass fiber, the mass ratio of the steel fiber and brass fiber is 1:1; the non-metal fiber is composed of aramid fiber and mineral fiber, and the aramid fiber The mass ratio of mineral fiber and mineral fiber is 1:2; the tackifier is composed of alumina, ferrochrome powder and silicon oxide, and the mass ratio of alumina, ferrochrome powder and silicon oxide is 3:7:4; the Described lubricant is made up of flake graphite an...

Embodiment 2

[0052] The present embodiment provides a friction material, including the following raw materials: 10g of binder, 24g of metal fiber, 8g of non-metal fiber, 50g of tackifier, 4g of elastic particles, and 7g of lubricant; the binder is modified by nitrile Phenolic resin, boron modified phenolic resin, liquid cashew nut shell oil modified phenolic resin form, the mass ratio of described nitrile modified phenolic resin, boron modified phenolic resin, liquid cashew nut shell oil modified phenolic resin is 2:1: 2; the metal fiber is composed of steel fiber and brass fiber, the mass ratio of the steel fiber and brass fiber is 1:0.8; the non-metallic fiber is composed of aramid fiber and mineral fiber, and the aramid fiber The mass ratio of mineral fiber and mineral fiber is 1:4; the tackifier is composed of alumina, ferrochrome powder and silicon oxide, and the mass ratio of alumina, ferrochrome powder and silicon oxide is 1:3:2; the Described lubricant is made up of flake graphite ...

Embodiment 3

[0059] The present embodiment provides a friction material, including the following raw materials: 14g of binder, 19g of metal fiber, 11g of non-metallic fiber, 45g of tackifier, 10g of elastic particles, and 4g of lubricant; the binder is modified by nitrile Phenolic resin, boron modified phenolic resin, liquid cashew nut shell oil modified phenolic resin form, the mass ratio of described nitrile modified phenolic resin, boron modified phenolic resin, liquid cashew nut shell oil modified phenolic resin is 5:3: 2; the metal fiber is composed of steel fiber and brass fiber, the mass ratio of the steel fiber and brass fiber is 1:1.2; the non-metallic fiber is composed of aramid fiber and mineral fiber, and the aramid fiber The mass ratio of mineral fiber and mineral fiber is 3:4; the tackifier is composed of iron oxide, aluminum powder and silicon oxide, and the mass ratio of iron oxide, aluminum powder and silicon oxide is 5:8:4; the lubricating agent Agent is made up of flake ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com