Method for improving traction force and braking power of wheel of traction engine and thermal treatment equipment

A technology for heat treatment equipment and wheel treads, applied to heat treatment equipment, heat treatment furnaces, wheels, etc., can solve the problems of no processing, etc., and achieve the effects of increasing wear resistance, enhancing traction ability, and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

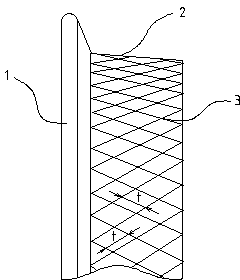

[0011] by attaching figure 1 It can be seen that the heat treatment equipment for processing the wheel tread bosses of traction locomotives in this scheme can use heat treatment technology on the wheel tread surface 2 of the wheel 1 to process the surface of the wheel tread surface 2 into regular and uniform bosses 3, the convex The height of platform 3 is between 0.5-1 mm, and the hardness is between 35-45HRC. The boss 3 described in this specific embodiment is a mesh boss 3, the height of the boss 3 is 0.8 mm, and the hardness is 40HRC. The distance t between adjacent lines formed by the meshed bosses 3 is 15 mm.

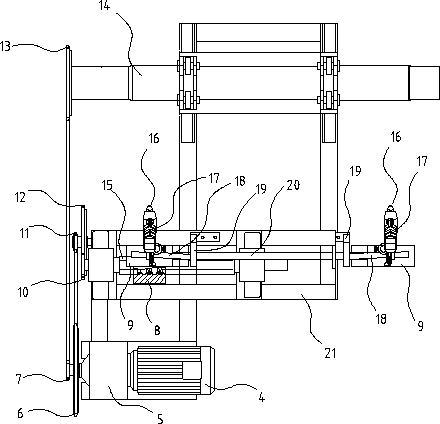

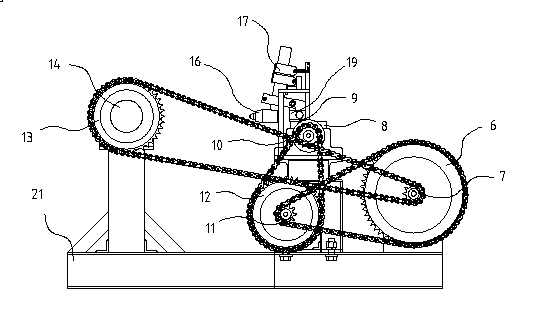

[0012] by attaching figure 2 and 3 It can be seen that the structure of the heat treatment equipment used to process the wheel tread boss of the traction locomotive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com