Coal flow control device based on CAN bus

A CAN bus and control device technology, which is applied in the field of coal flow control devices based on CAN bus, can solve the problems of conveyor idling, intelligent control start and stop, failure to detect parking in time, etc., and achieve the effect of preventing idling and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

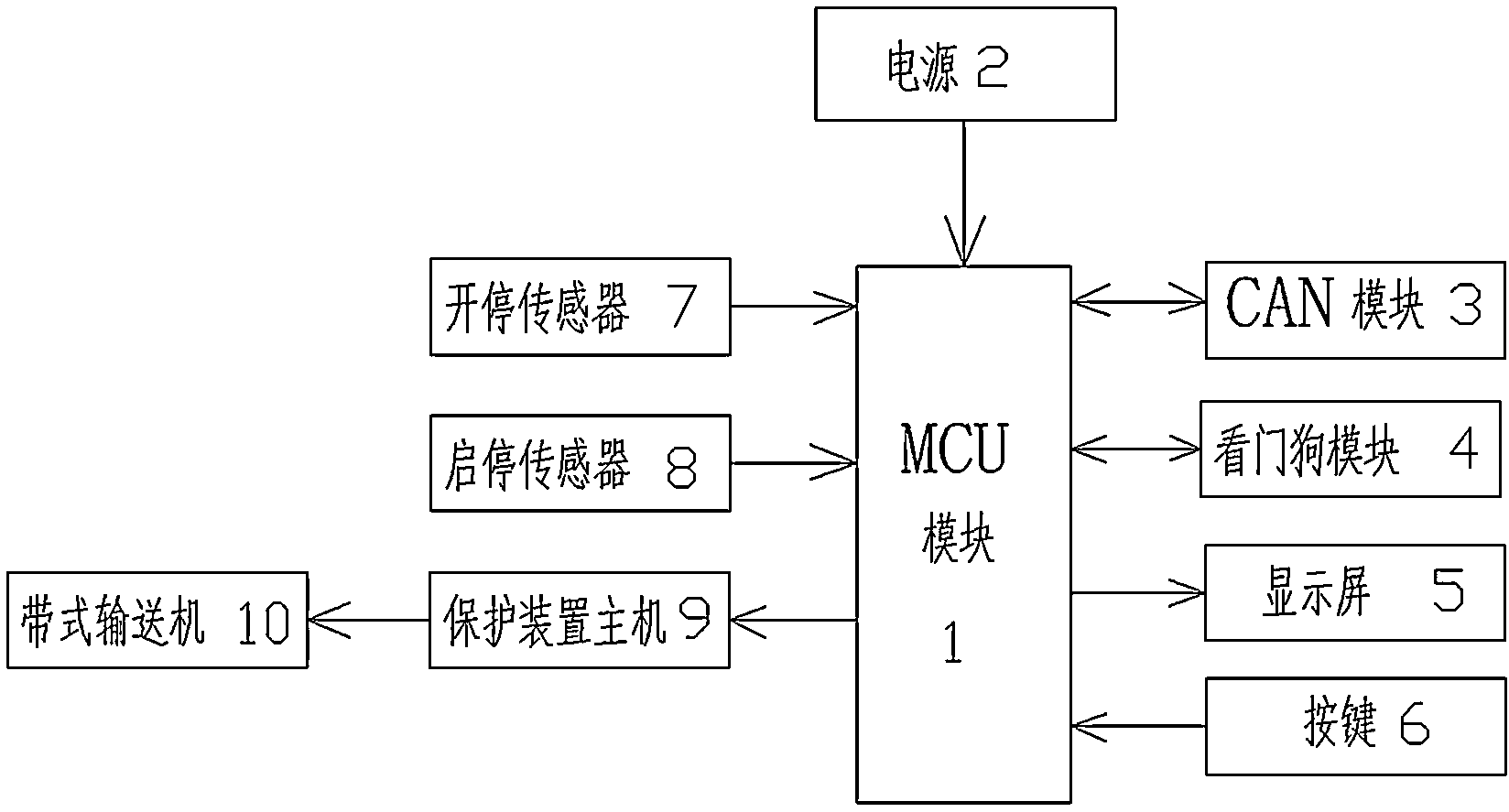

[0014] Such as figure 1 As shown, a coal flow control device based on CAN bus provided by the present invention includes an MCU module 1, and the periphery of the MCU module 1 is provided with a CAN module 3 connected to it, a display screen 5, a watchdog module 4 and buttons 6, The periphery of the MCU module 1 is also provided with a power supply 2 for the control device; the opening of the MCU module 1 is connected with the start-stop sensor 7 of the belt conveyor and the start-stop sensor 8, and the opening of the MCU module 1 is connected to the belt conveyor. 10 protection device host 9; the MCU module 1, CAN module 3, watchdog module 4 and power supply 2 are all set in the intrinsically safe control box, and the display screen 56 and buttons 6 are set on the surface of the intrinsically safe control box , the key 6 can include "shun start", "reverse start", "stop" and "emergency stop". CAN bus communication circuit, watchdog module 4 can adopt CAT1023 chip.

[0015] c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com