Novel axial-symmetry convergence and expansion spray pipe using single actuation system

A single-action, axisymmetric technology, applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems that the front-end hot-end components cannot be blocked, the control law is complicated, and the control law is uncontrollable. It achieves good stealth function, simple control law, The effect of high structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

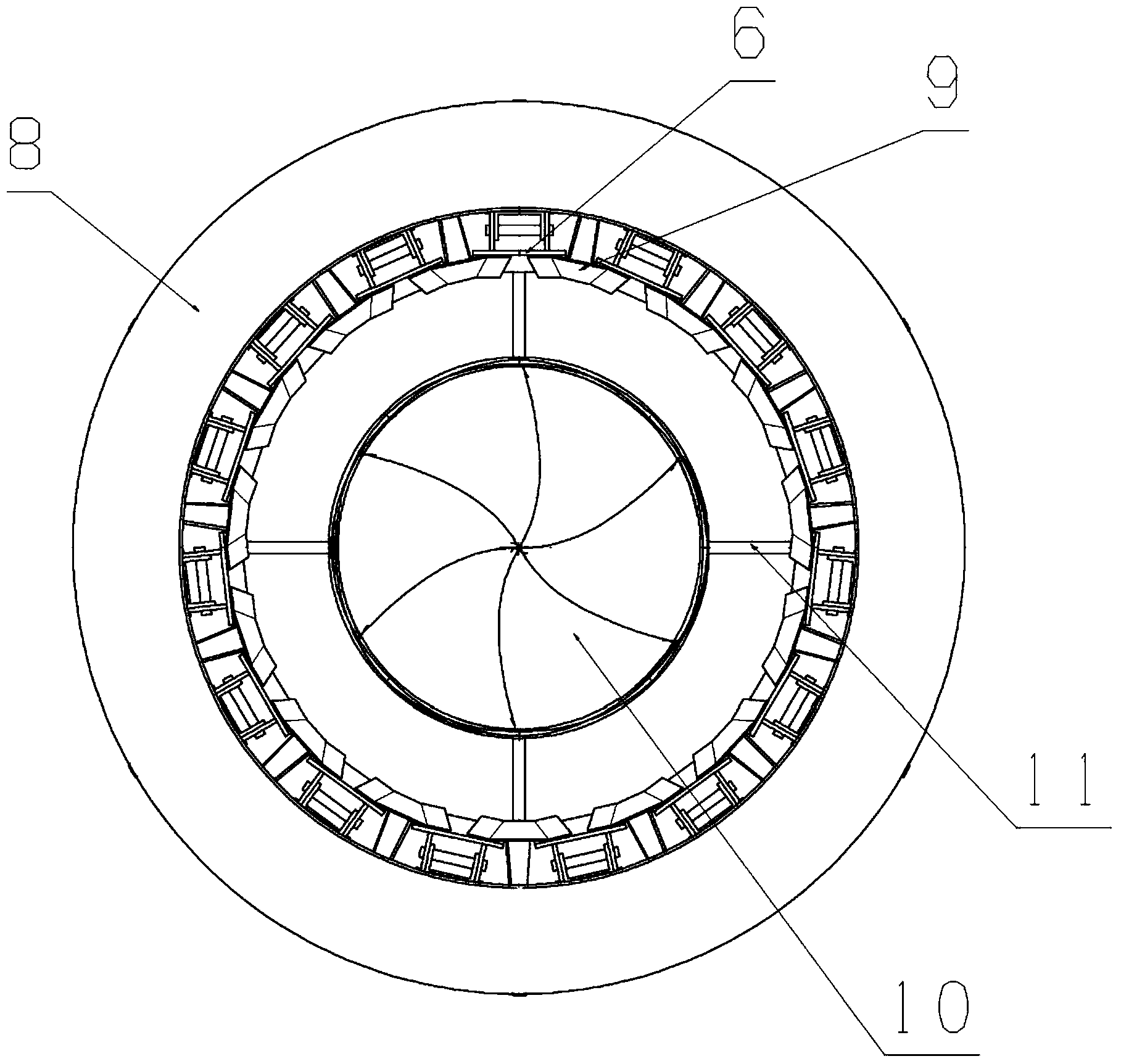

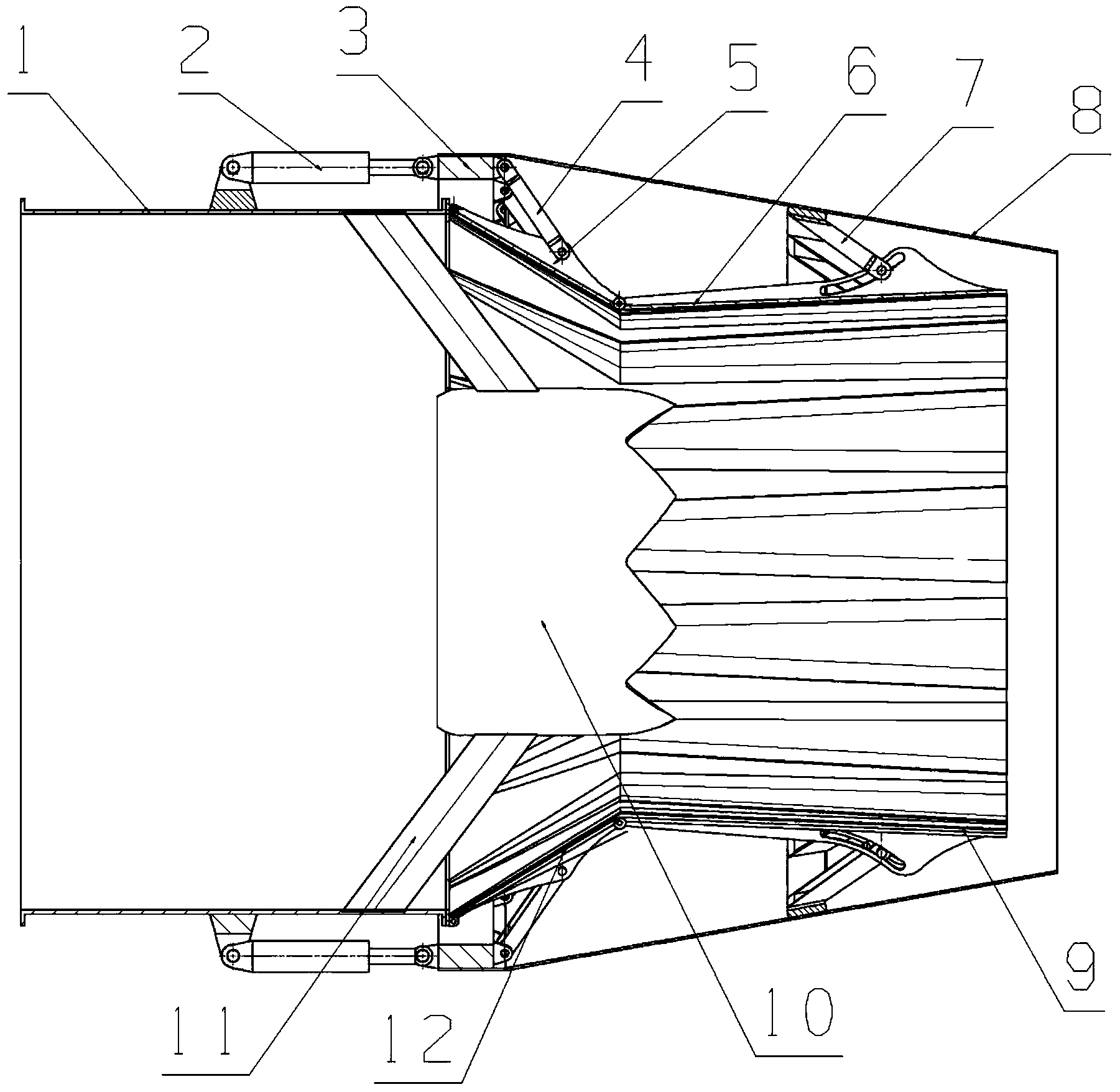

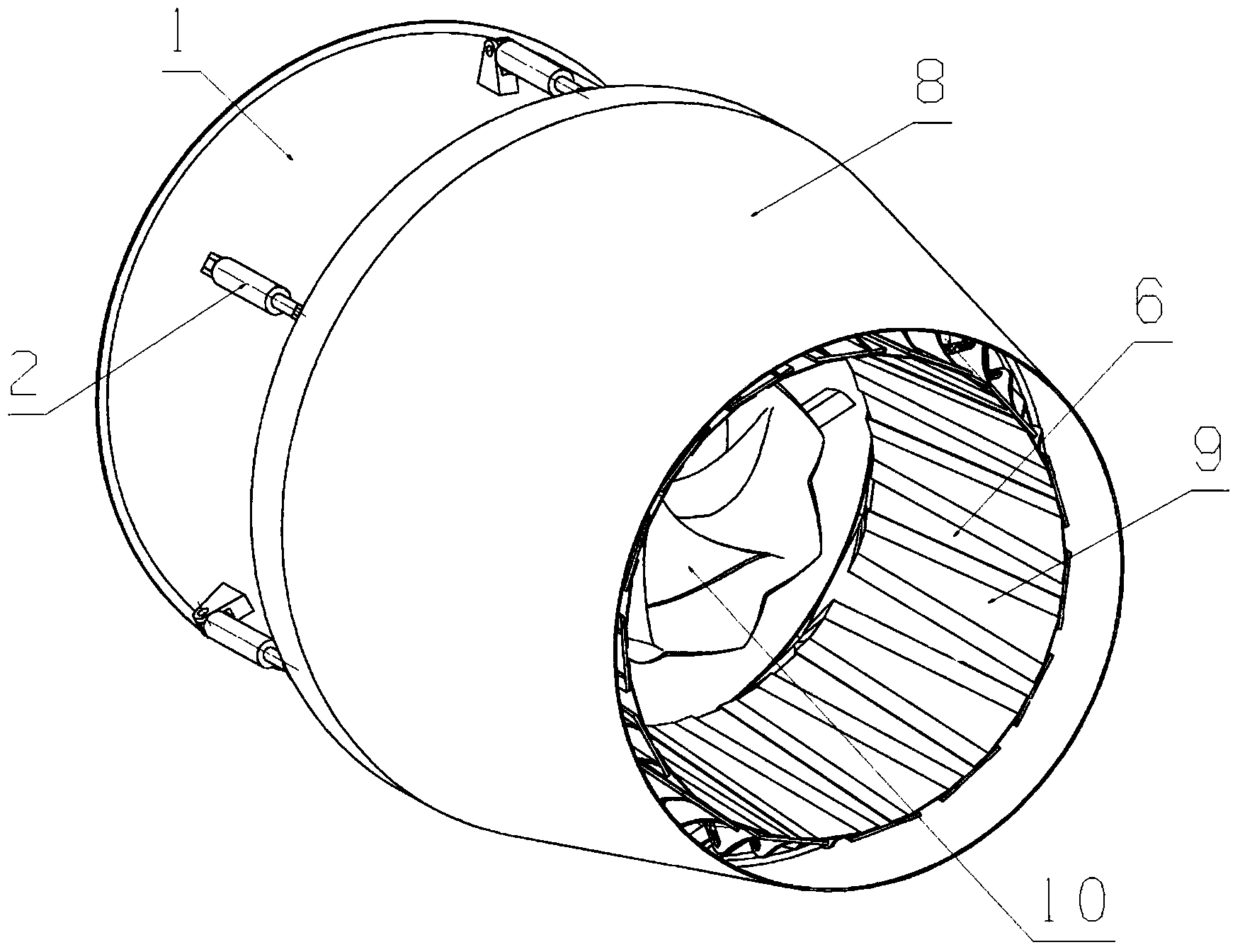

[0031] A novel single-action system axisymmetric retractable nozzle consists of a cylinder 1 , a drive adjustment mechanism, a sealing member, a central shielding member and an outer cover 8 . Specifically:

[0032] The front end of the cylinder body 1 is connected with the engine as a supporting member for the entire nozzle.

[0033] The driving adjustment mechanism is composed of a cylinder 2, a pull rod 4, a convergence adjustment plate 5, an expansion adjustment plate 6 and a bracket 7. Among them, the actuator 2 is arranged along the circumferential direction of the nozzle, the front end is connected to the outer wall of the barrel 1 through a mechanical connection, and the rear end is directly connected to the tie rod 4 through a rotating pair or other synchronous mechanism; the tie rods 4 are evenly distributed along the circumferential direction of the nozzle, The other end is connected to the outer middle section of the convergence adjustment plate 5 through a rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com