Rubber-coated expansion bolt

A technology of expansion bolts and rubber covering, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve problems such as weak force, achieve the effects of increasing friction, preventing the movement of polished rods, and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

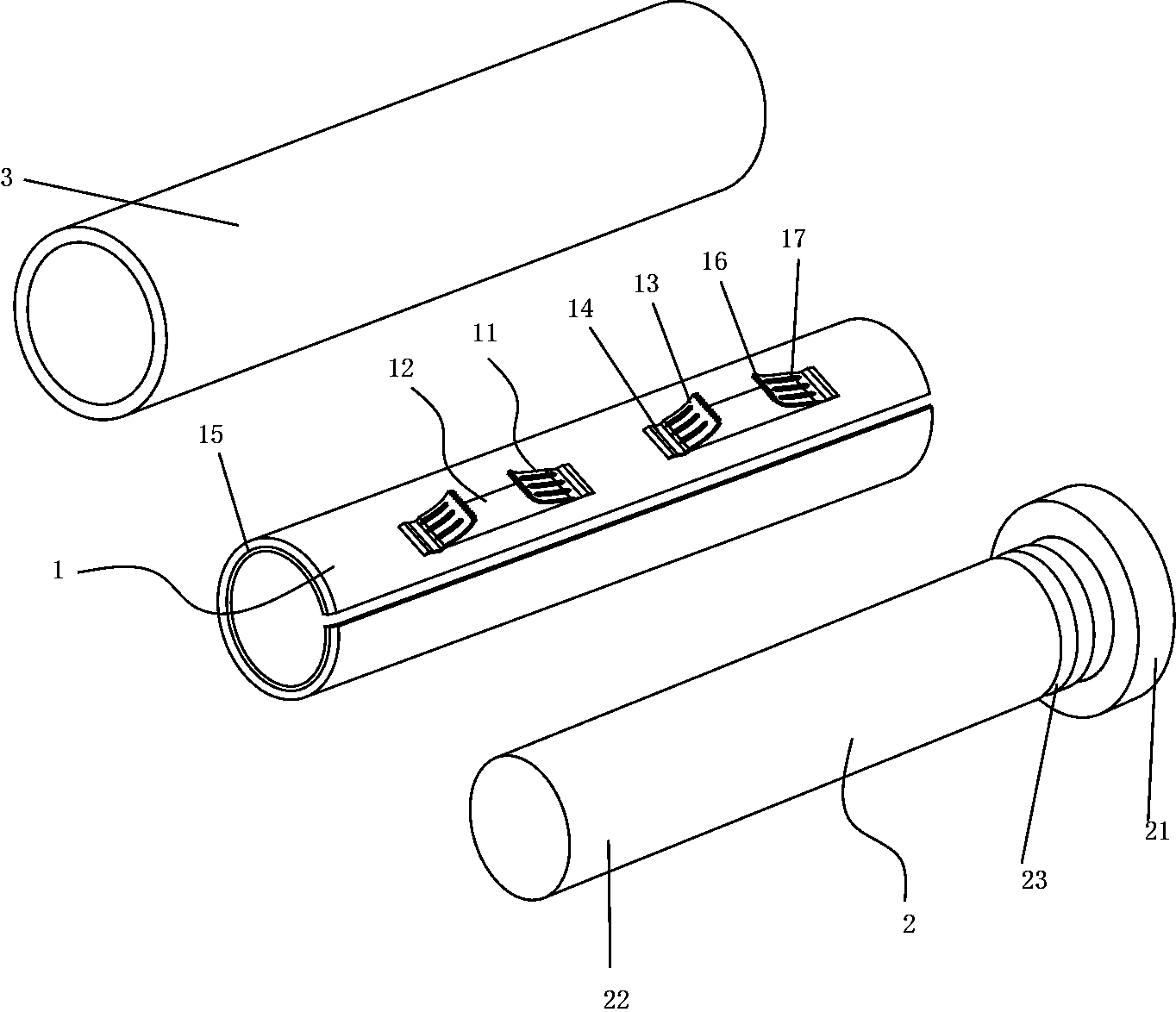

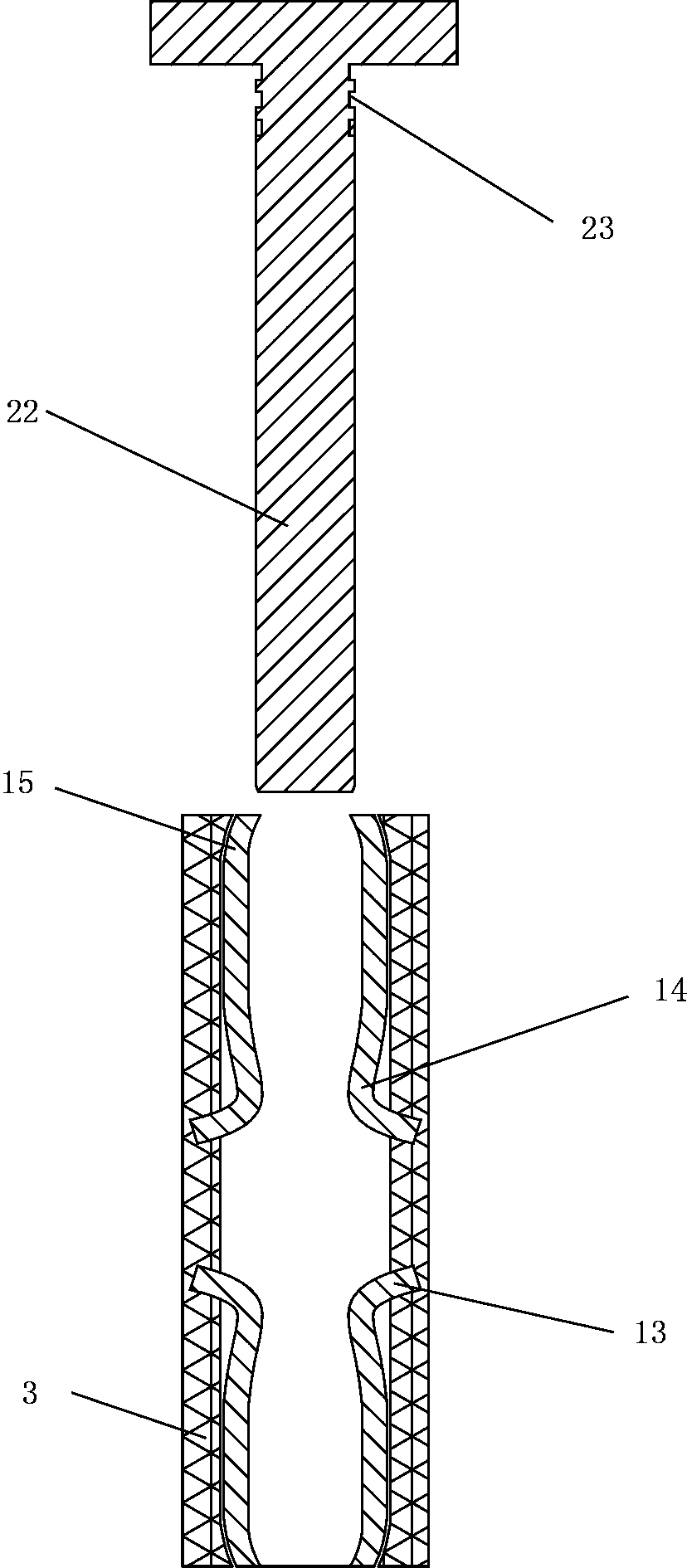

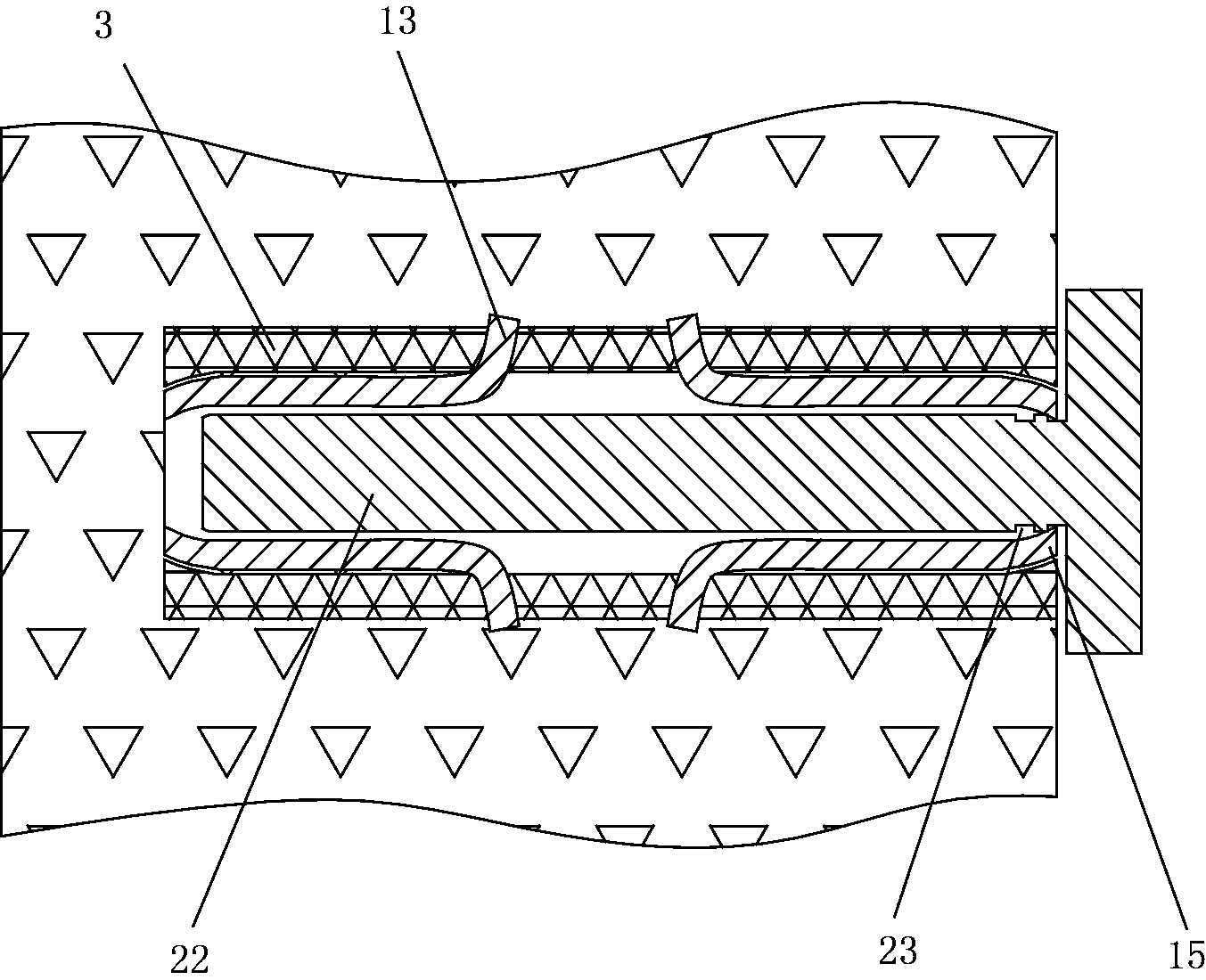

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: figure 1 , figure 2 , image 3 with Figure 4 As shown in the figure, the markings are as follows: casing 1, inner rod 2, outer rubber layer 3, punching flap 11, expansion part 12, eversion part 13, inner concave part 14, punching beam mouth 15, sawtooth 16, reinforcement groove 17 , round flat head 21, polished rod 22, annular groove 23.

[0016] The rubber-covered expansion bolt is a kind of expansion bolt suitable for soft materials such as wood. It includes a sleeve 1 and an inner rod 2. The sleeve 1 is rolled from a steel plate. The outer side of the sleeve 1 is provided with an outer rubber layer 3. After the rubber layer and the casing 1 are manufactured, the outer rubber layer 3 is made, which is in direct contact with the inner wall of the wooden hole and is not easy to pull out after insertion. The casing 1 is provided with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com