Method for accurately determining high-temperature mechanical property parameters of heat preventing material based on digital image related technology

An image-related, high-temperature mechanics technique, applied in the direction of using stable bending force to test material strength, using stable tension/pressure to test material strength, analyzing materials, etc. Light and other issues, to achieve comprehensive mechanical response, strong repeatability, and real effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

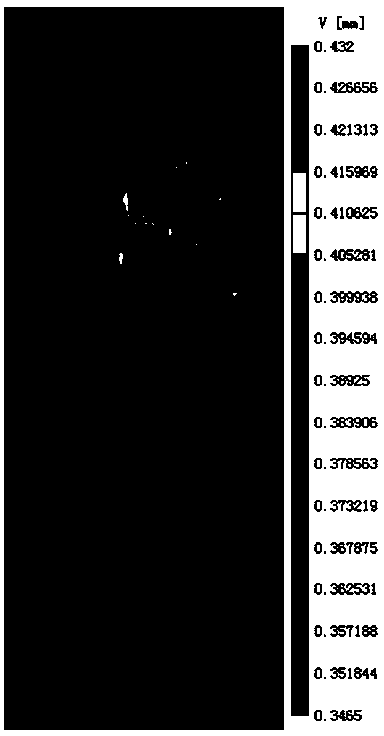

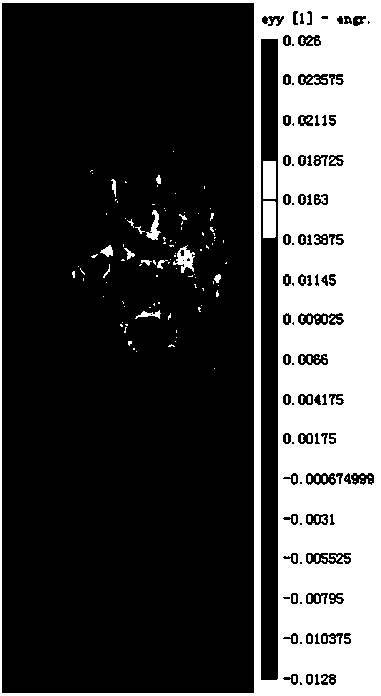

[0022] Take the high-temperature tensile test of graphite materials in vacuum and at 1200°C as an example to illustrate:

[0023] 1. Set up two DIC optical lenses near the observation window outside the vacuum furnace of the high-temperature mechanical testing machine, respectively install blue filters in front of the two lenses, and install two blue supplementary light sources at the windows. The purpose is because at high temperature, the sample will be red and shiny, but the ceramic powder on the surface of the sample will not shine, so the powder sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com