Soil beam bending test device

A technology of bending test and soil beam, which is applied in the direction of testing material strength by applying a stable bending force, can solve the problems of single function, poor precision, simple test data collection method, etc., and achieve high data measurement accuracy, large selection space, The effect of rate stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail in conjunction with the accompanying drawings and examples.

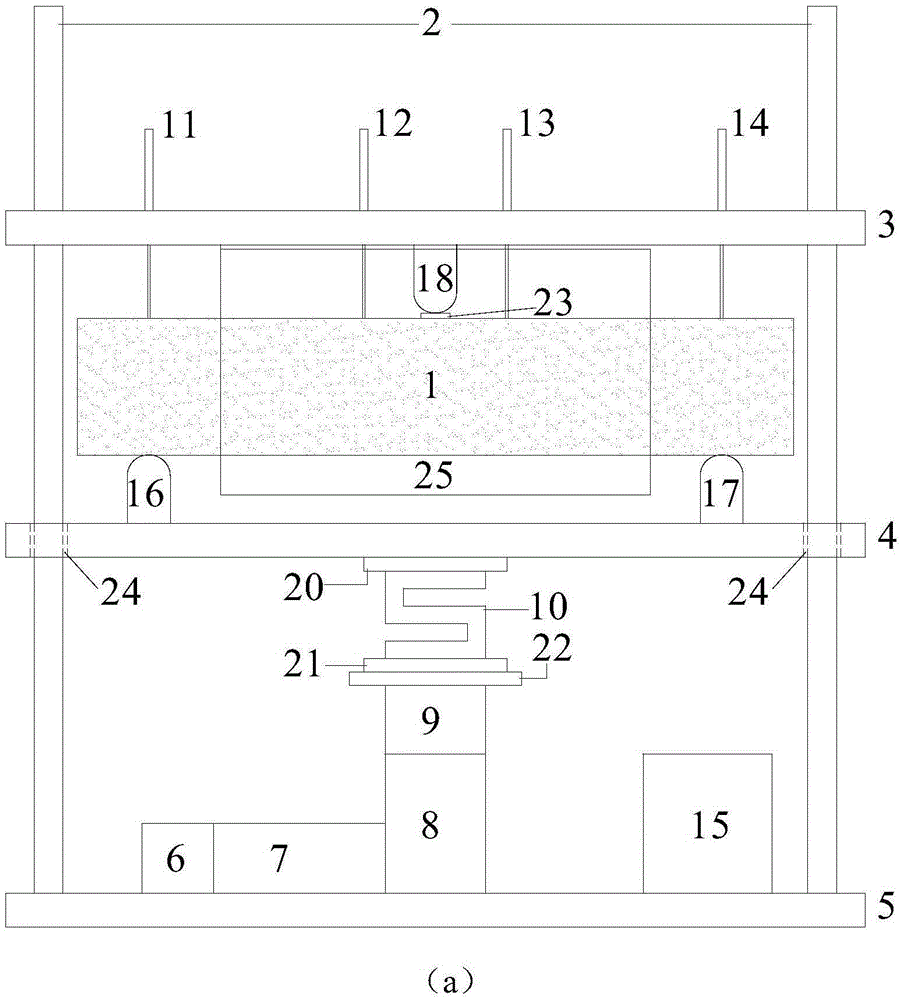

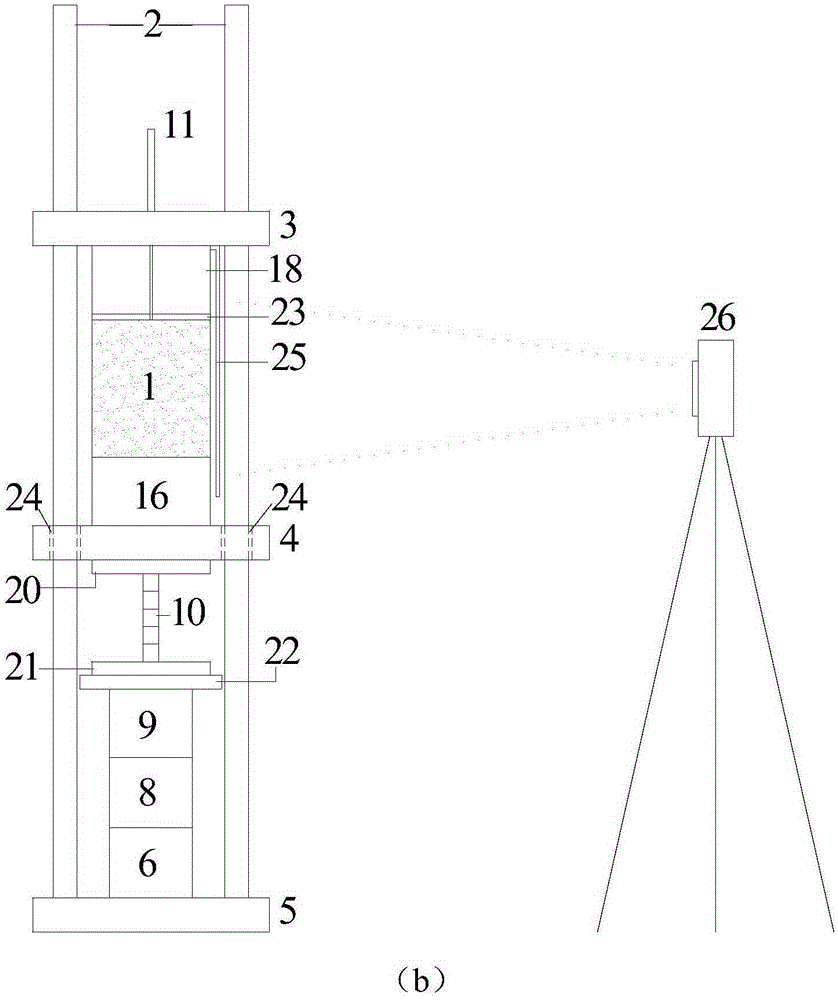

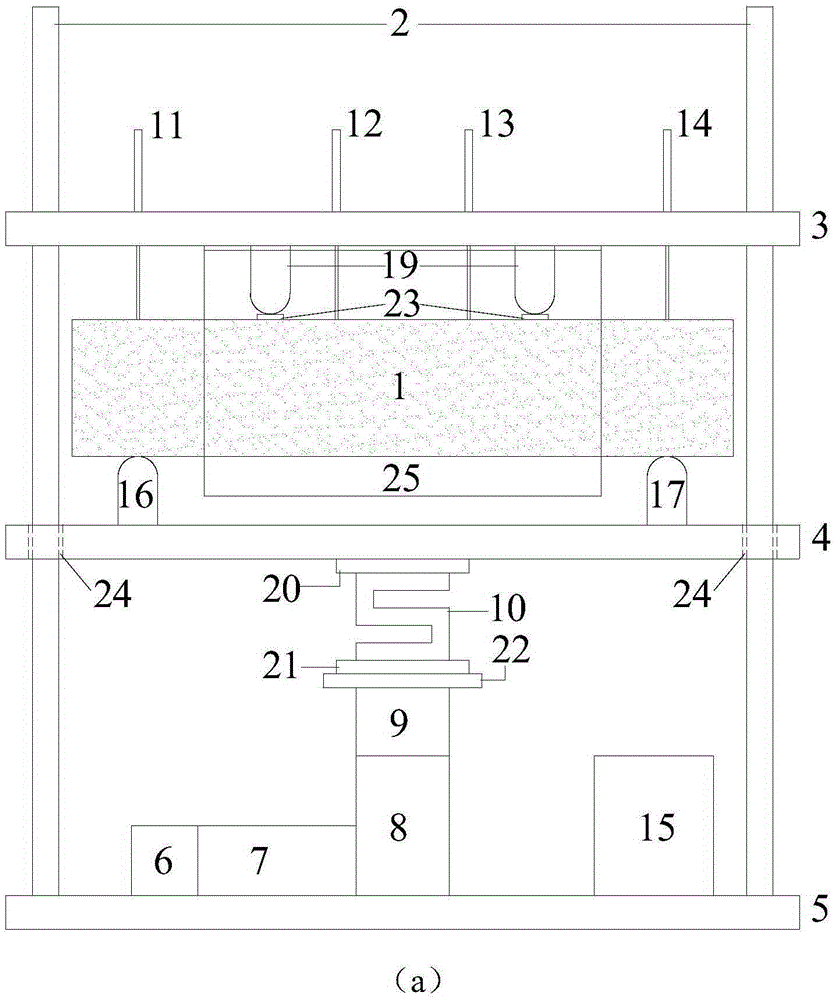

[0017] like Figure 1-2 As shown, a soil beam bending test device of the present invention includes: four steel rods 2, three steel plates 3-5, a servo controller 6, a motor 7, a planetary reducer 8, a ball screw lifter 9, and a force sensor 10 , four displacement sensors 11-14, static data acquisition instrument 15, first support 16, second support 17, three spacers 20-22, plexiglass plate 25, high-definition camera 26;

[0018] Wherein, the bottom ends of the four steel rods 2 are all anchored with the third steel plate 5, the tops of the four steel rods 2 are all anchored with the first steel plate 3, and the second steel plate 4 is located between the first steel plate 3 and the third steel plate 5, The second steel plate 4 is connected with four steel rods 2 through four linear sliders 24; the first support 16 and the second support 17 are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com