On-line quality inspection device for diamond wire particles based on machine vision

A technology of machine vision and diamond wire, which is applied in the direction of measuring devices, particle and sedimentation analysis, instruments, etc., can solve the problems of difficult control of the detection process and slow detection speed, and achieve the effect of fast detection speed and improved clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

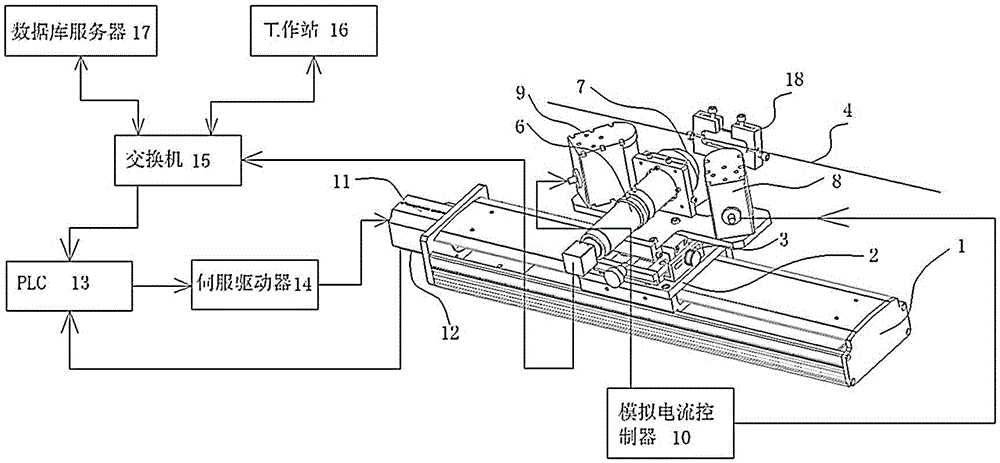

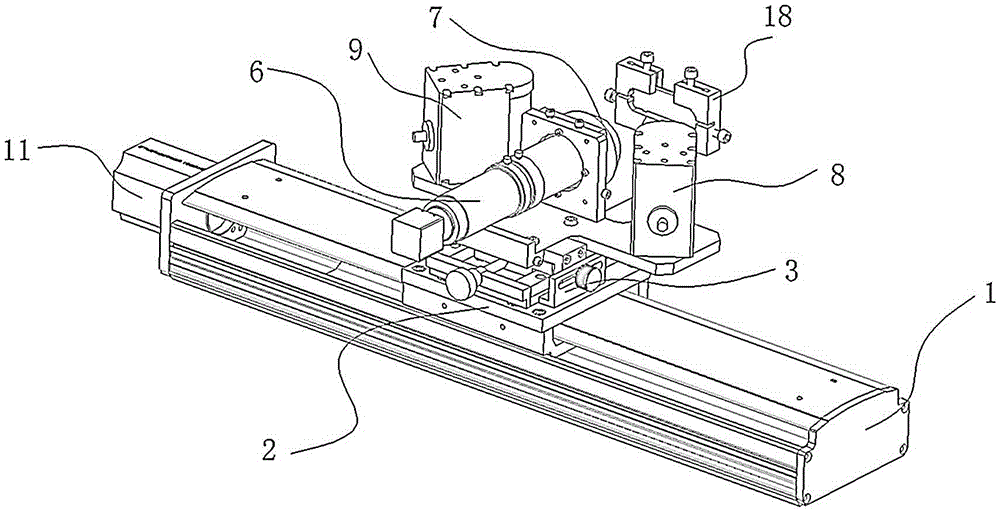

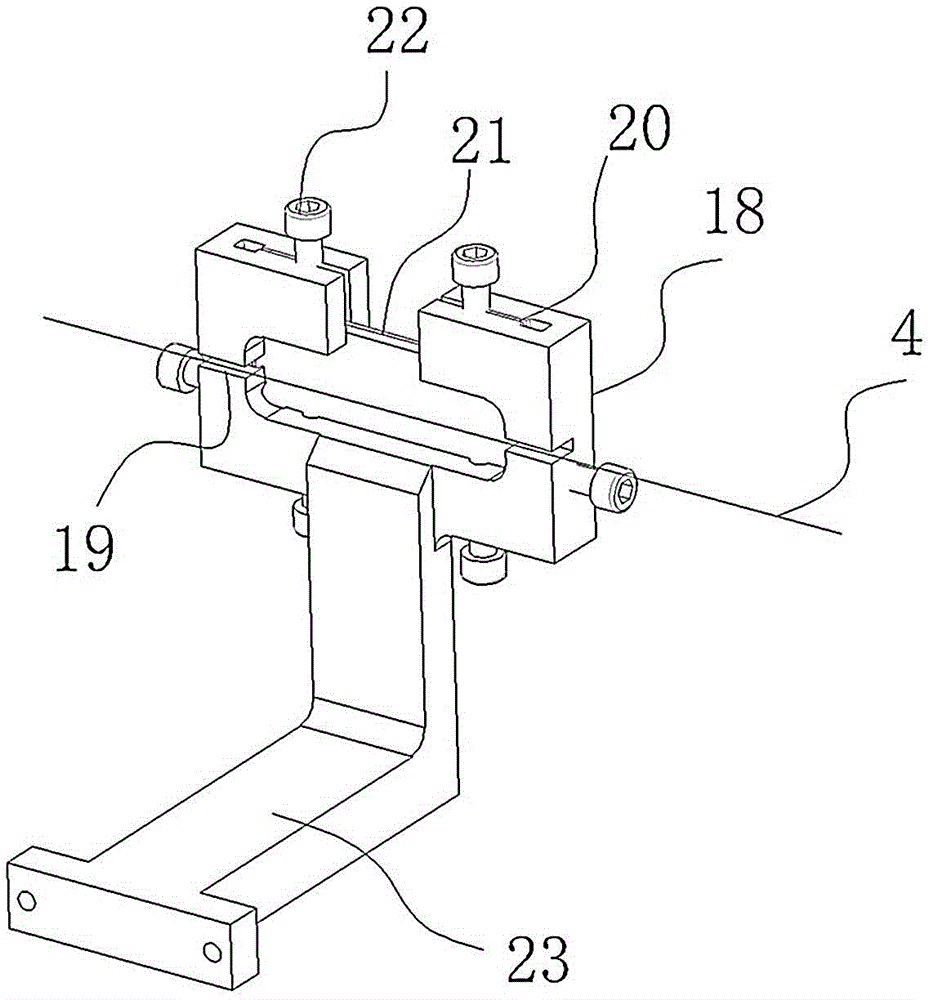

[0021] combine figure 1 and figure 2 As shown, a machine vision-based online quality inspection device for diamond wire particles provided by the present invention includes a single-axis mechanical arm 1 that moves a slider 2 along the axial direction of the diamond wire 4, and an optical displacement stage 3 is provided on the slider 1 , the single-axis manipulator 1 of the present embodiment can adopt the TL135-L10-S350-BD-P200 of CCTL Company, its maximum movement speed is 0.5m / s, repeat positioning accuracy ± 0.02mm; Cooperate with the microscope lens 7 and the camera 6 for photographing the diamond wire 4, and the camera can be adjusted axially and radially through the optical displacement stage 3. Since the diamond wire and the particles consolidated on it are very small in geometric size, Among them, the outer diameter of the diamond wire ranges from 0.10 to 0.50 mm, and the particle size ranges from 10 to 60 μm. Therefore, 7 microscope lenses with short focal length,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com