On-line quality inspection method of diamond wire particles based on machine vision

A technology of machine vision and diamond wire, applied in particle and sedimentation analysis, instrumentation, particle size analysis, etc., can solve the problems of slow detection speed and difficult control of the detection process, and achieve the effect of fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

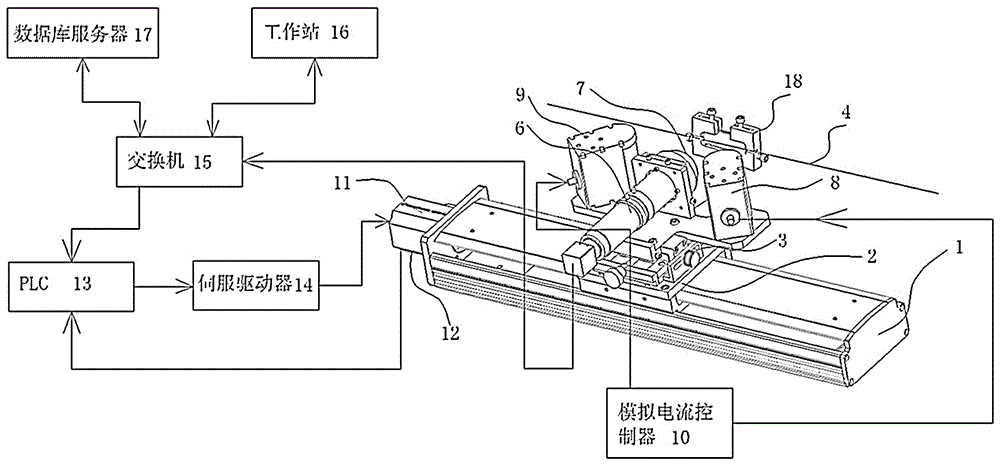

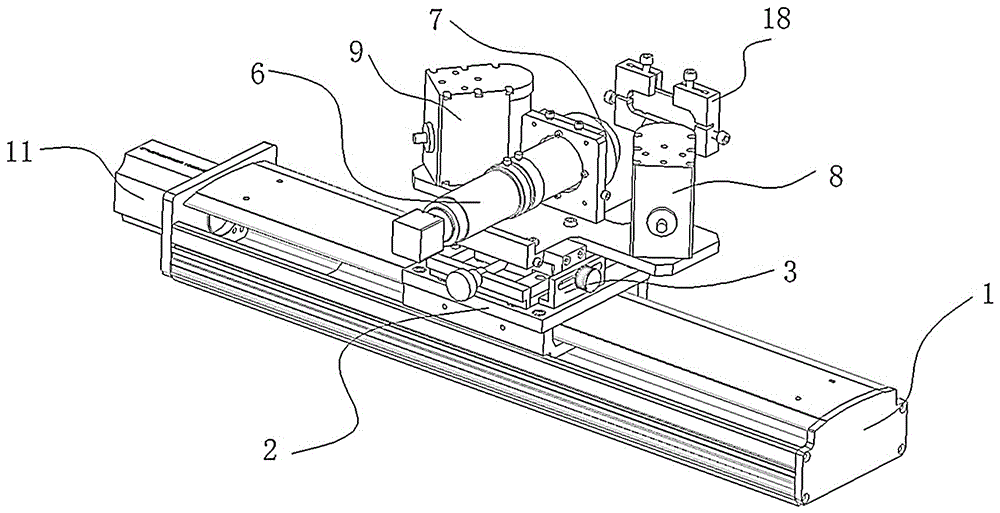

[0026] The present invention provides a method for online quality inspection of diamond wire particles based on machine vision, comprising the following steps:

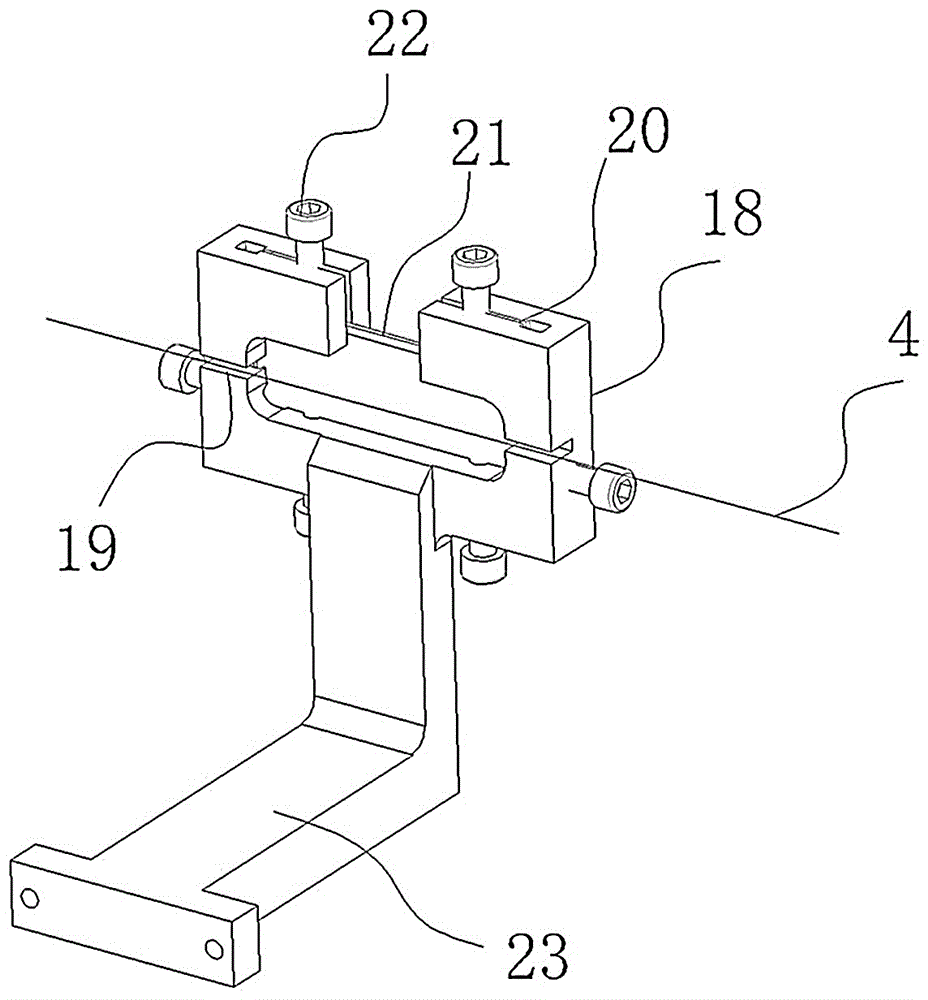

[0027] a) combine figure 1 and figure 2 As shown, a single-axis manipulator 1 with a slider 2 moving along the axial direction of the diamond wire 4 is provided, and an optical displacement stage 3 is provided on the slider 1. The uniaxial manipulator 1 of this embodiment can adopt the TL 135- L10-S350-BD-P200, its maximum moving speed is 0.5m / s, repeat positioning accuracy is ±0.02mm; the optical displacement stage 3 is equipped with a microscope lens 7 and a camera 6 that cooperate with each other to shoot the diamond wire 4, through the optical The translation stage 3 can adjust the camera axially and radially. Since the geometric size of the diamond wire and the particles consolidated on it is very small, the outer diameter of the diamond wire ranges from 0.10 to 0.50mm, and the particle size range is 10-60µm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com