Method for detecting heat dissipating property of metal heat dissipation device and testing device thereof

A heat dissipation device and heat dissipation performance technology, which is applied in the field of detection of heat dissipation performance of metal heat dissipation devices and its testing device, can solve the problems of detection and evaluation of comprehensive heat dissipation performance, and achieve the effects of optimized design, simple experimental equipment, and simple operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

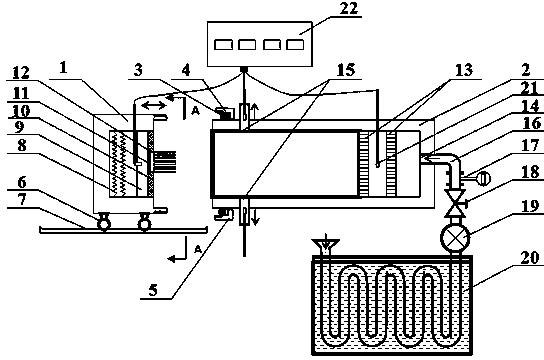

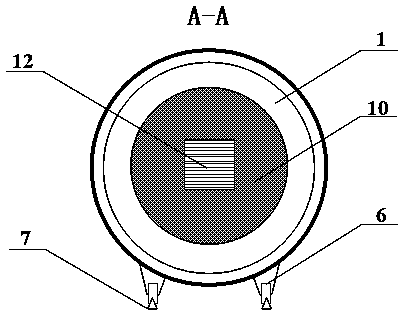

[0033] In this example, see figure 1 and figure 2 , a test device for detecting the heat dissipation performance of metal heat dissipation devices, including a closed device cavity and a temperature analysis and detection system, the device cavity is divided into two independent spaces for heat insulation by a heat insulating wall 10, forming a left end cavity 1 and a right end Cavity 2, the metal heat dissipation device 12 to be tested is placed in the device cavity, and the heated end and heat dissipation part of the metal heat dissipation device 12 to be tested are respectively located in the left end cavity 1 and the right end cavity 2, and the temperature analysis and detection system is composed of a heat source 8. A temperature sensor 21 and a data acquisition record analyzer 22 are formed. The heat source 8 is located in the cavity space where the heated end of the metal heat dissipation device 12 to be tested is located. The heated end of the metal heat dissipation d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com