Piston cylinder arrangement of an aerostatic liner compressor

A technology of linear compression and aerostatic bearings, applied in parts of pumping devices for elastic fluids, machines/engines, pump components, etc., can solve problems such as reducing efficiency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

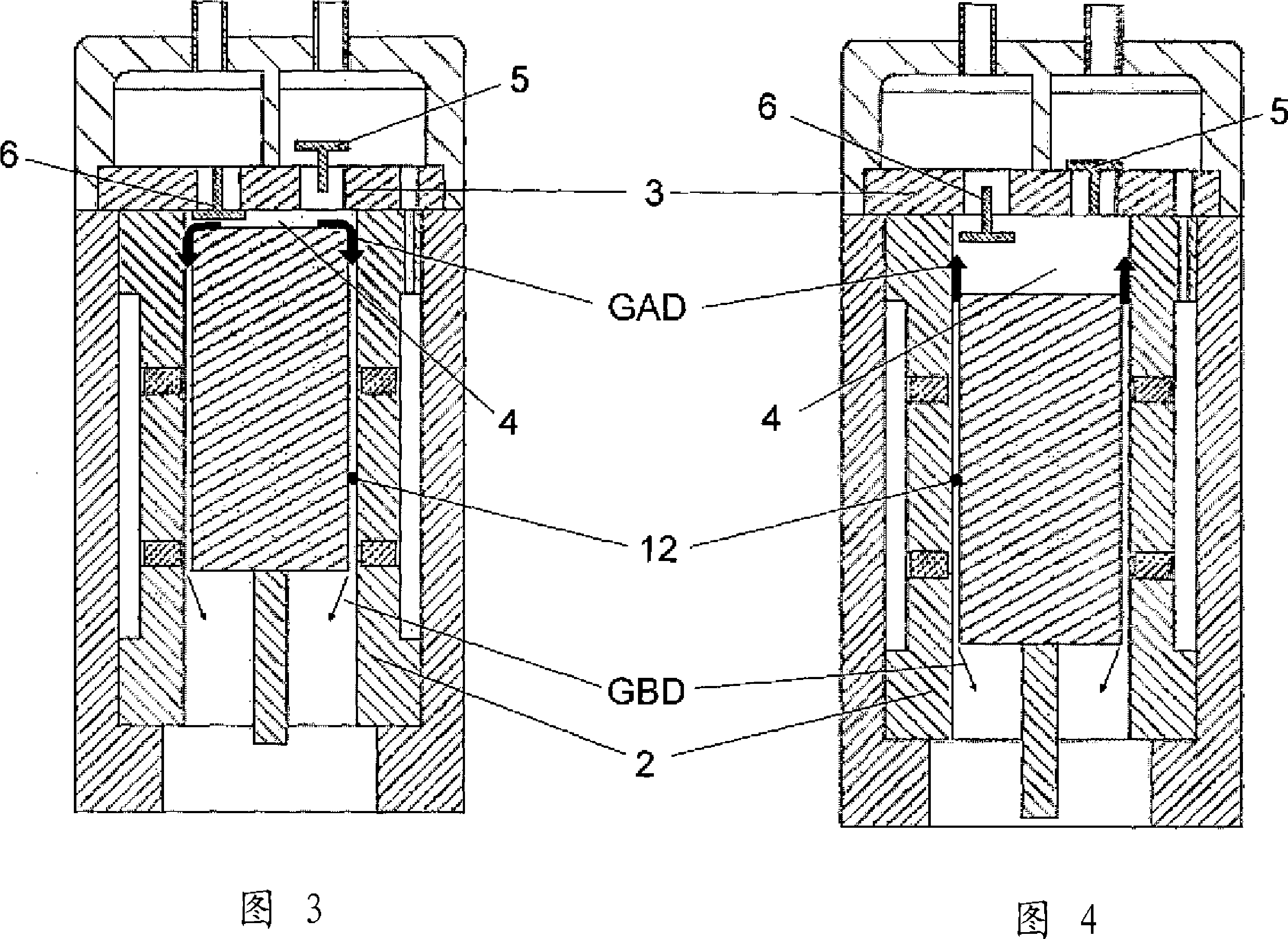

[0048] The present invention proposes technical improvements for the piston / cylinder assembly of a linear compressor with an aerostatic bearing arrangement, including improvements in energy efficiency and production process.

[0049] According to the operating principle of the cooling circuit and as figure 1 As shown, the gas compression mechanism is preferably realized by the axial and oscillatory movement of the piston 1 inside the cylinder 2 . A discharge valve 5 and a suction valve 6 for regulating the entry and exit of gas into and out of the cylinder 2 are arranged at the cylinder head 3 . It should also be noted that the piston 1 is actuated by an actuator 7 connected to a linear compressor motor, which is not the object of further elaboration in this document.

[0050] The piston 1 of the compressor has the function of producing a linear alternating movement when actuated by a linear motor, thereby providing the movement of the piston 1 within the cylinder 2, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com