Device design capable of automatically adjusting preheating position of cutting gun and application of device design

A technology of automatic adjustment and cutting gun, applied in the field of continuous casting flame cutting machine equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

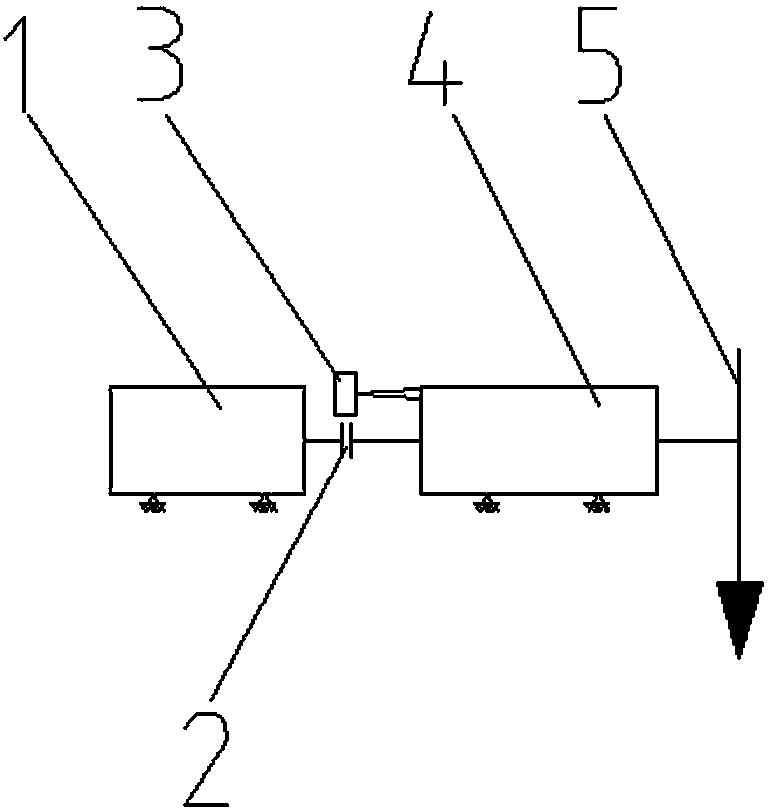

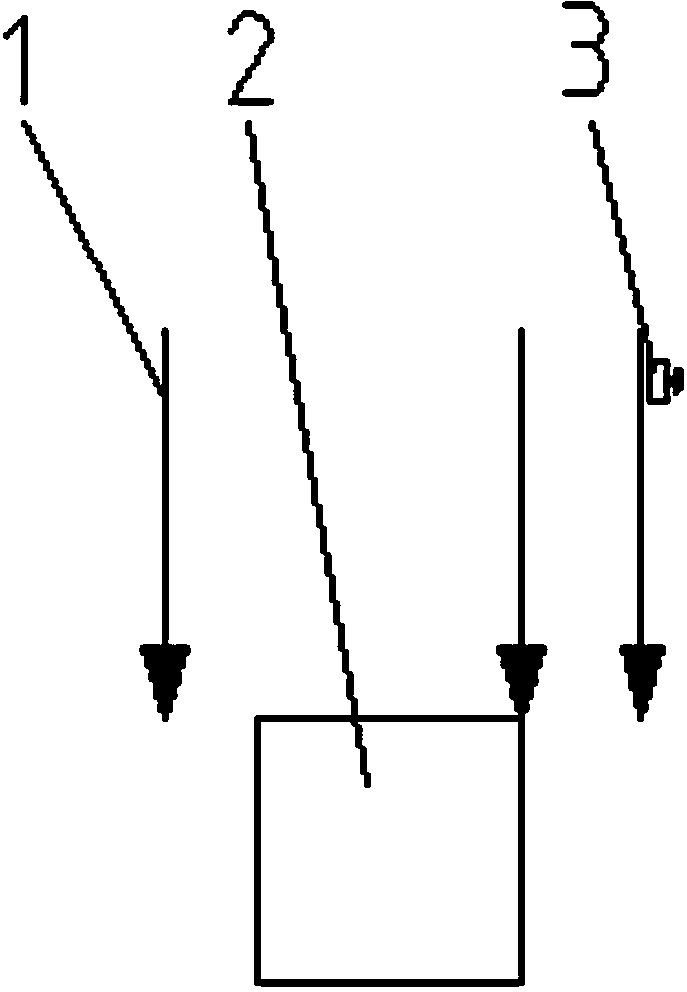

[0014] see figure 1 , a device that can automatically adjust the preheating position of the cutting torch, including a motor 1, a stopper 2 is installed on the output shaft of the motor 1, a counting proximity switch 3 is installed on the reducer, and the other end of the output shaft is connected with the reducer 4, see figure 2 It is required that the installation position of the original cutting torch in-situ proximity switch 3 should be moved to the opposite position of the cutting direction, and there is a distance x from the edge of the slab 2 that needs to be cut, and the whole device is controlled by the PLC controller.

[0015] The design method of the above-mentioned device that can automatically adjust the preheating position of the cutting torch is: see figure 1 , when the motor 1 rotates a circle, the PLC controller judges the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com