Pendulum bob type shearing-resistant impact testing machine and testing method thereof

An impact testing machine and hammer technology, which is applied in the direction of testing the strength of materials using a single impact force, can solve the problems that the impact hammer is easy to produce errors, affect the testing accuracy, time-consuming and laborious, and achieve the effect of improving the testing accuracy and efficiency.

Active Publication Date: 2014-09-17

NORTHEASTERN UNIV

View PDF8 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the lack of standard test equipment for testing shear impact resistance, designers still cannot use shear impact resistance as a design parameter

Although the Chinese patent "Magnetic switch controlled drop hammer flexural impact test bench" with application number 102680334A came out in 2012 and achieved multiple drop hammer flexural impact tests, due to repeated operations, it was time-consuming and laborious,

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

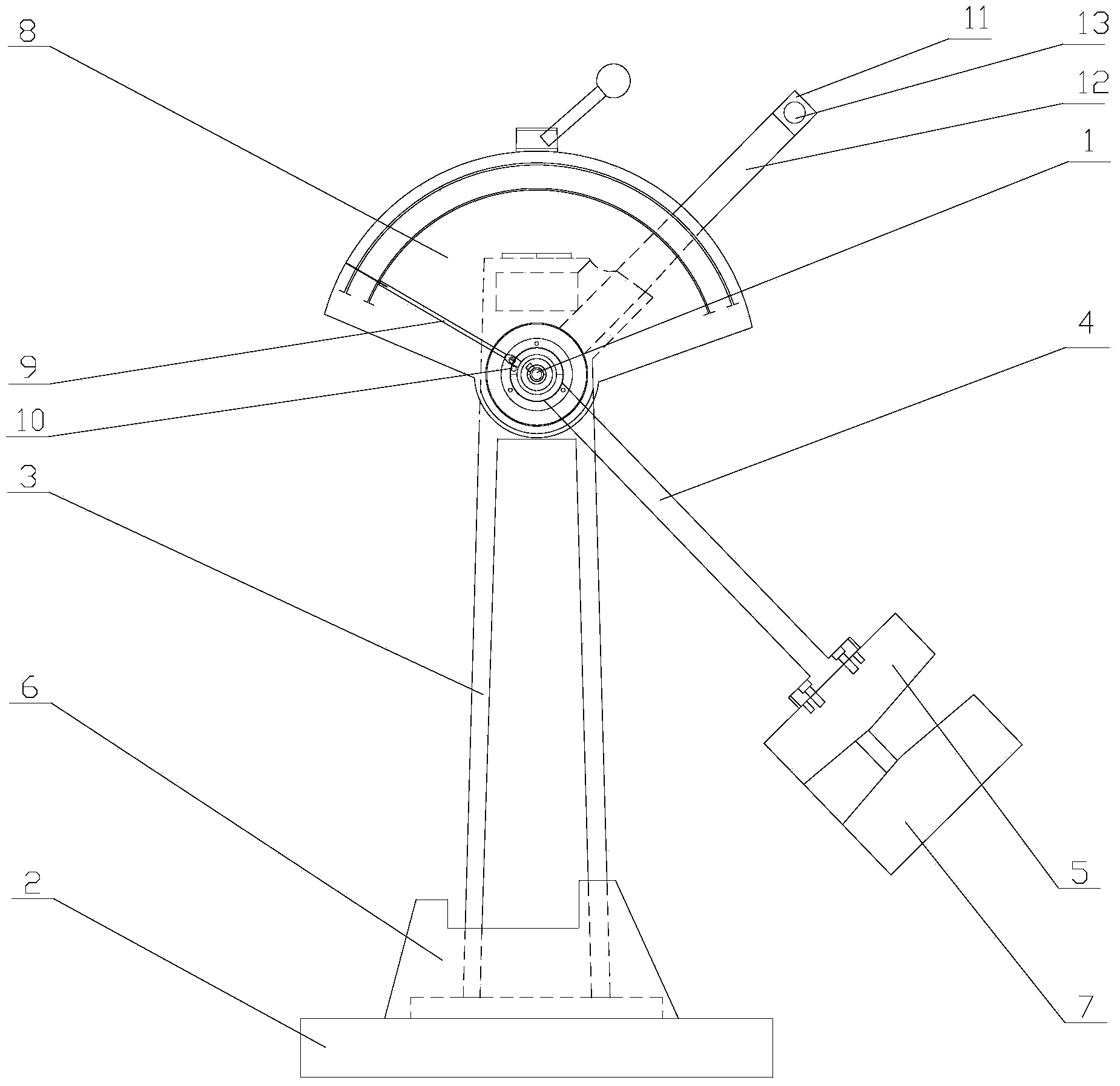

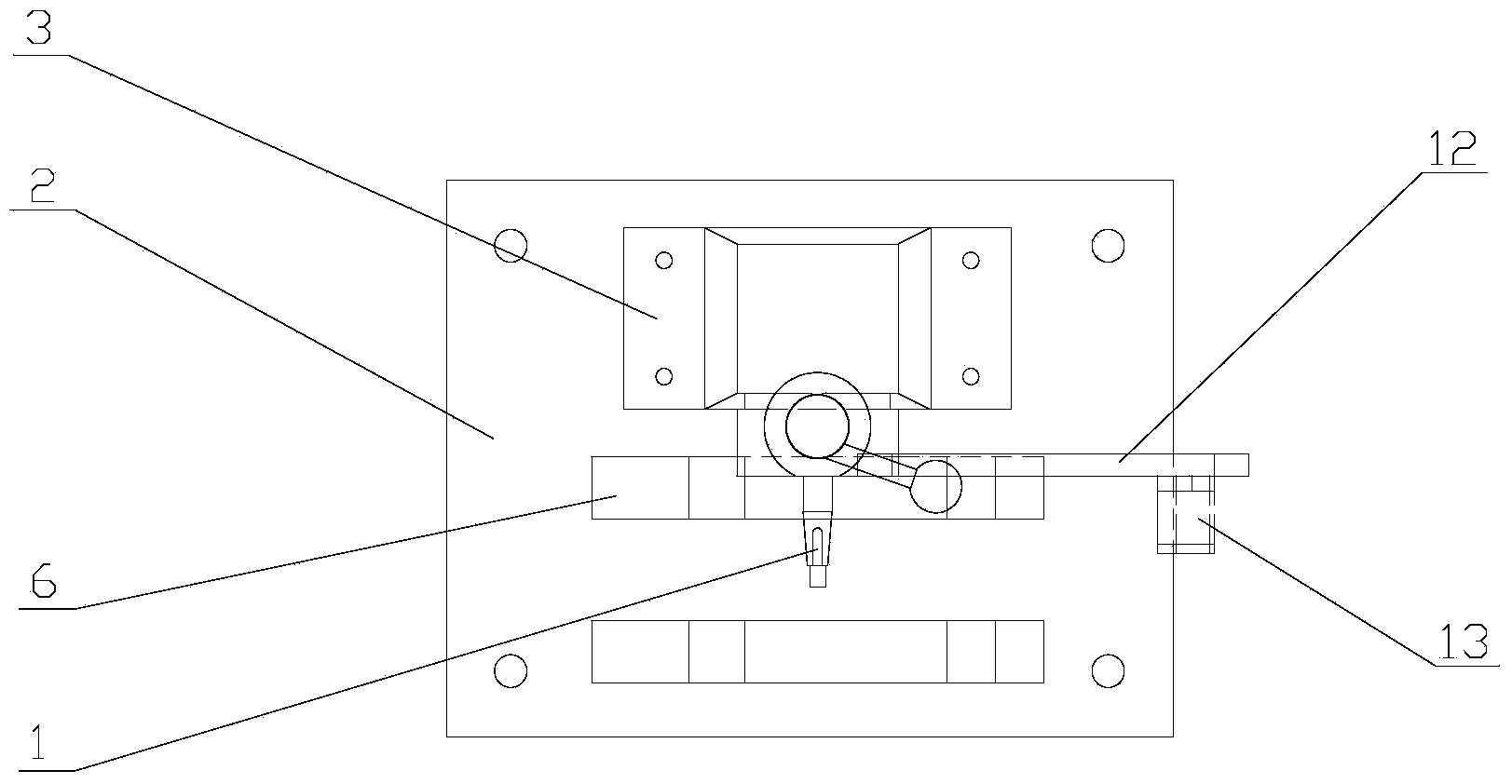

The invention relates to a pendulum bob type shearing-resistant impact testing machine and a testing method thereof, belonging to the technical field of concrete material testing. The pendulum bob type shearing-resistant impact testing machine can achieve accurate shearing-resistant impact testing result and wide application range, is convenient to carry, and can avoid danger to operators. The pendulum bob type shearing-resistant impact testing machine comprises a working shaft, a base, a support, a connecting frame, a pendulum bob, a pendulum rod, a graduated dial and a pointer; the testing method comprises the following steps: measuring the compressive strength of a test piece; horizontally placing the test piece on the support and recording the initial scale value of the pointer on the graduated dial; carrying out pendulum bob shearing-resistant impact on the front surface of the test piece; recording the ending scale value of the pointer on the graduated dial to obtain the difference of the initial scale value and the ending scale value; measuring a shearing-resistant impact force-displacement curve to obtain the shearing-resistant impact energy of the test piece; corresponding the shearing-resistant impact energy of the test piece to the difference of the initial value and the ending value.

Description

technical field [0001] The invention belongs to the technical field of concrete material testing, and relates to a pendulum type shear impact testing machine and a testing method. Background technique [0002] Compared with ordinary concrete, fiber reinforced concrete has significantly improved tensile strength, flexural strength (also known as bending strength, flexural strength), shear strength, and toughness. In recent years, domestic and foreign research on fiber-reinforced concrete has continued to deepen, and the application of fiber-reinforced concrete has become more and more extensive. Structures such as building beams, columns, bridges, pavements, and the ends of precast piles are mostly subjected to shear impact, and a considerable part of them belongs to bending shear impact. Therefore, it is of great practical significance to study the shear impact resistance of fiber reinforced concrete. [0003] For the experimental research on the shear impact resistance of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/30

Inventor 芮勇勤张宏肖让王成王荣杨保存李献灿

Owner NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com