A tube expansion method and tooling for a piece-cluster segmented oil cooler

A technology of oil cooler and tube expansion method, applied in the field of oil cooler tube expansion, can solve the problems of irregular heat sink, lamination, affecting the heat exchange performance of oil cooler and product appearance quality, etc., and achieve good product appearance quality , High heat exchange performance, and the effect of solving the problem of expanding tube laminations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

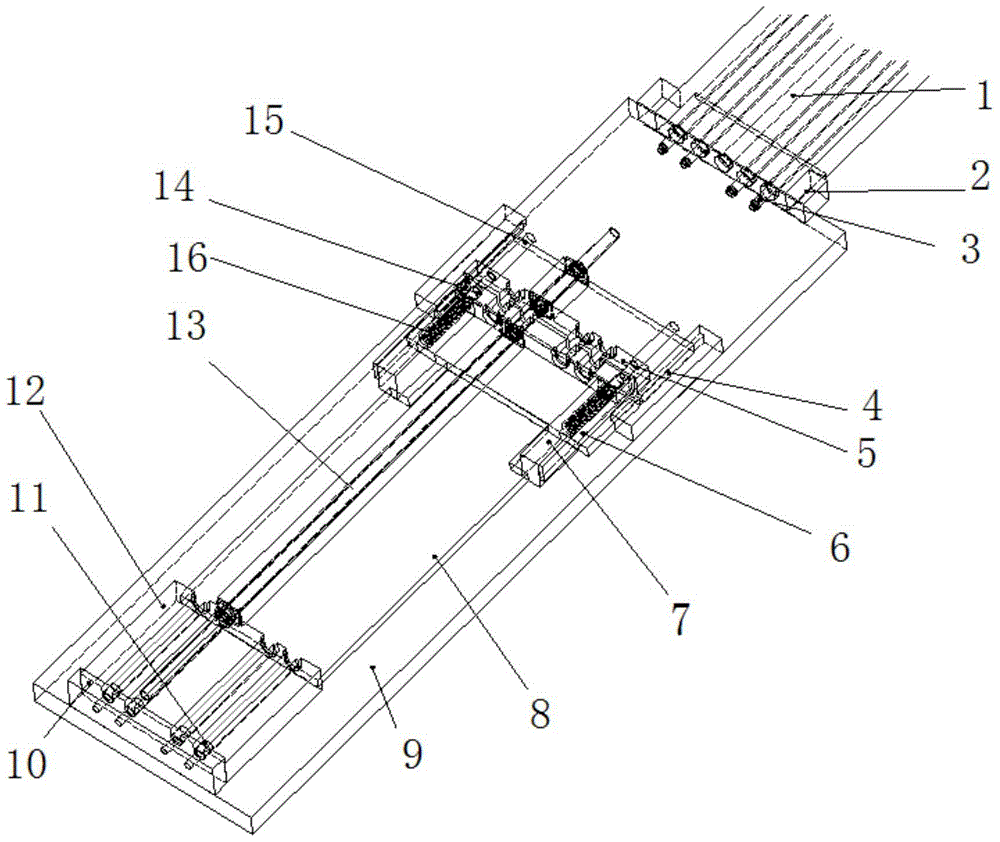

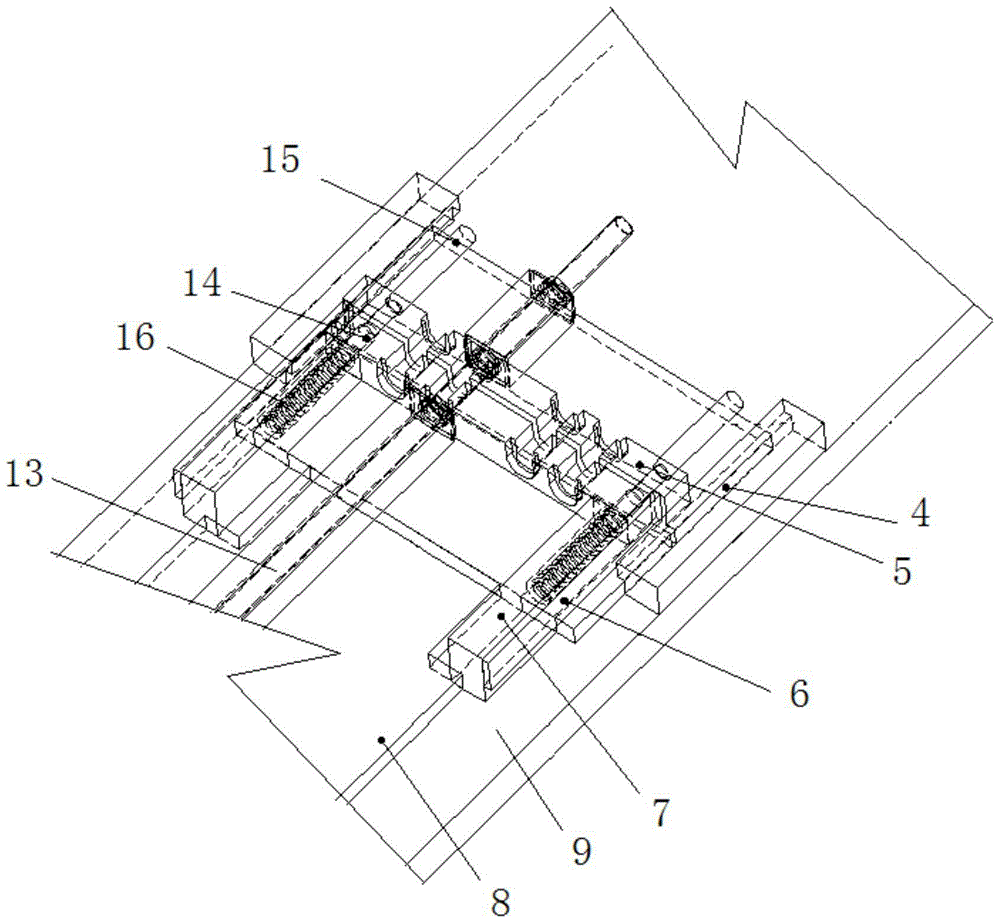

[0022] In this embodiment, a tube expansion method for segmented oil coolers of sheet clusters is as follows: figure 1 , 2 As shown, the segmented fin cluster oil cooler includes an oil pipe and the first fin cluster and the second fin cluster distributed outside the oil pipe; the first fin cluster and the second fin cluster are along the length of the oil pipe The direction is set, and there is a gap between the two, and the oil pipe between the first fin cluster and the second fin cluster is radially positioned, and in the axial direction of the oil pipe of the cluster segmented oil cooler , one end adopts the guide mechanism to guide the oil pipe axially, and the other end uses the expansion rod to expand the oil pipe until the expansion operation of the entire oil pipe is completed.

[0023] The radial positioning method of the oil pipe between the first fin cluster and the second fin cluster adopts a spring floating support mechanism to position the oil pipe on the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com