Drilling tapping machine

A technology of tapping machine and tooling fixture, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of application limitation, inability to provide multi-station processing at the same time, and difficulty in meeting the processing requirements of special parts, and achieve the improvement The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

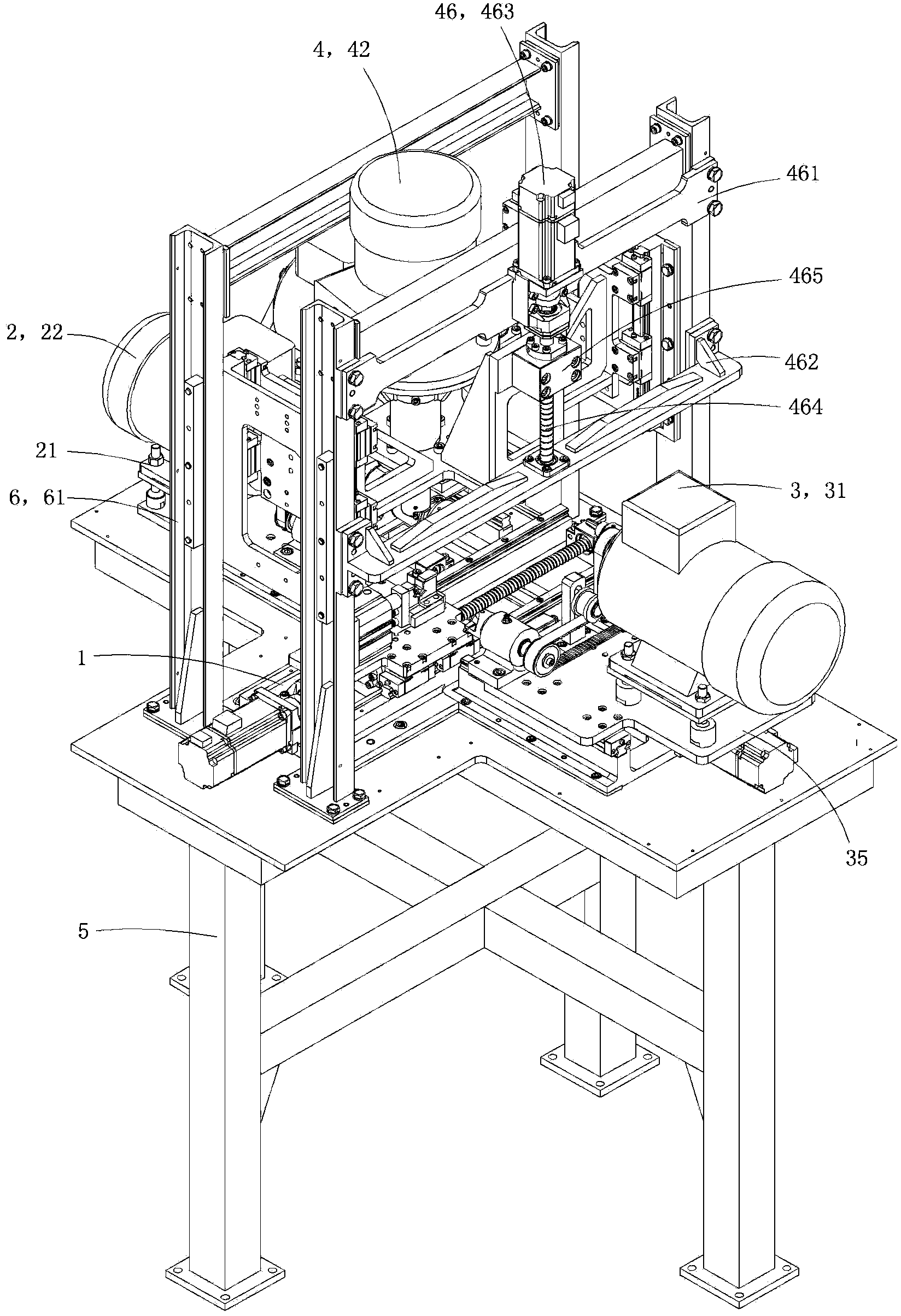

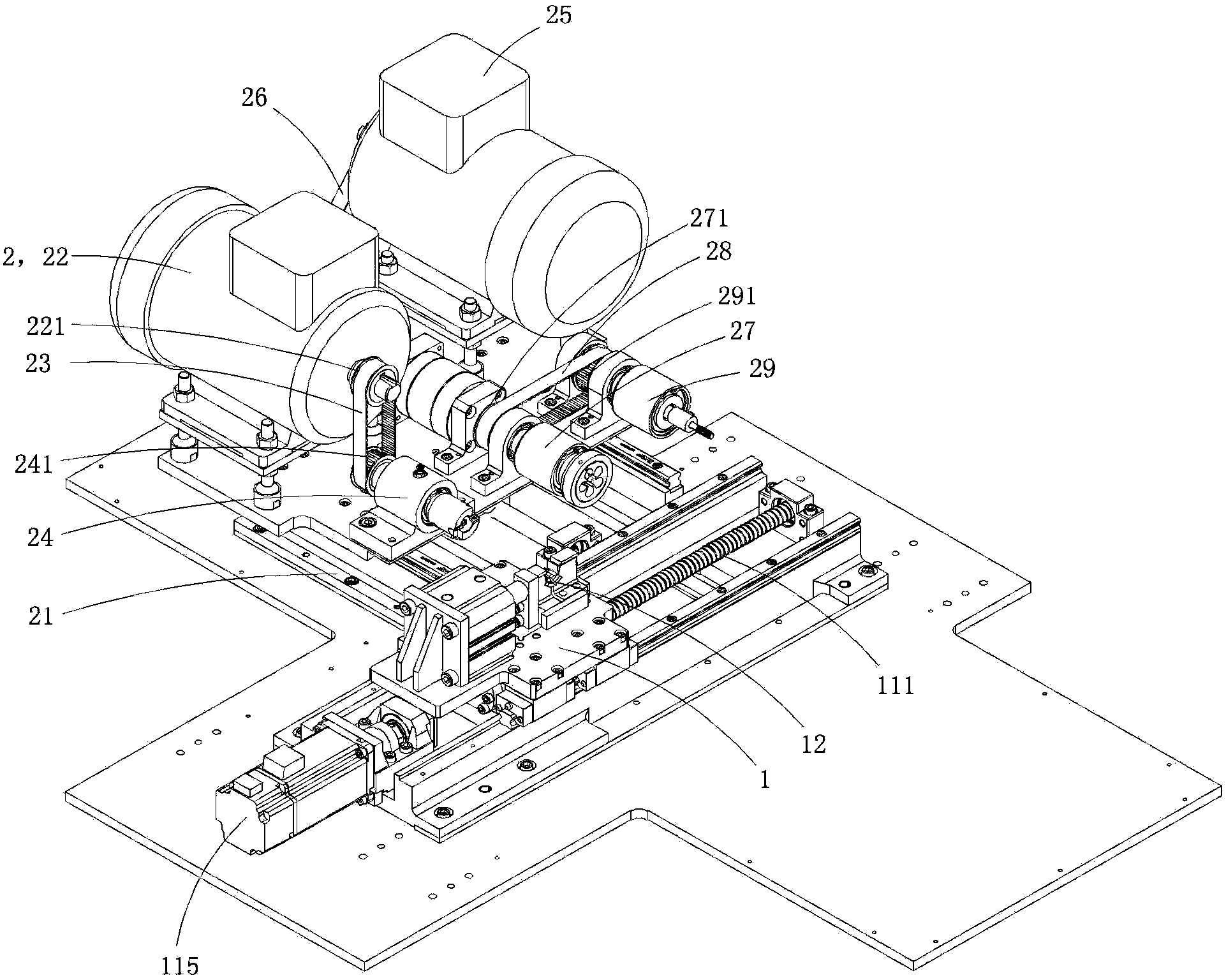

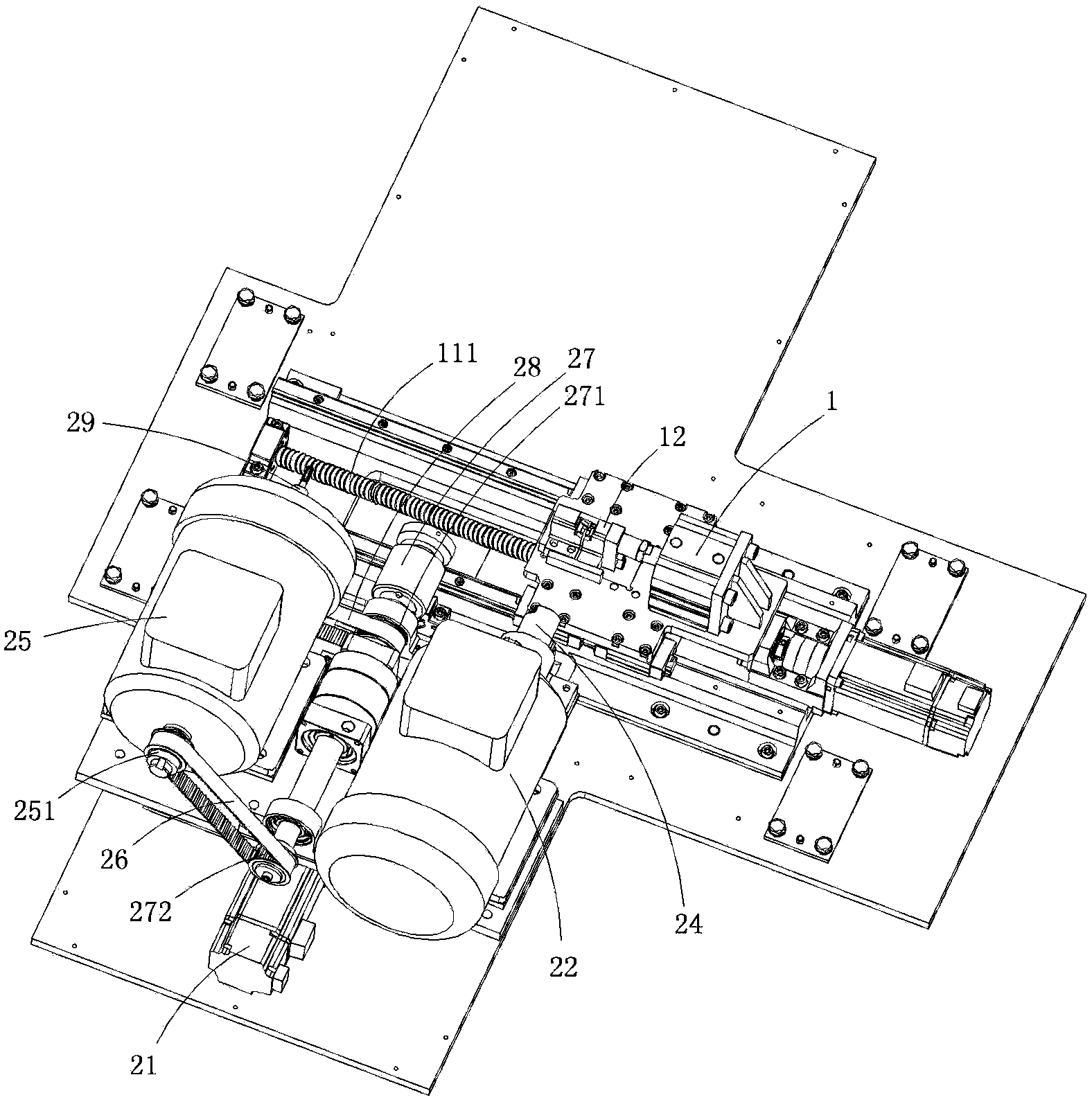

[0015] Figure 1 to Figure 8 A specific embodiment of the invention is shown in which, figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 for figure 1 A schematic diagram of the three-dimensional structure of the left processing components and fixtures in the drilling and tapping machine shown; image 3 for figure 2 A schematic diagram of the three-dimensional structure of the left processing assembly and fixture viewed from another angle; Figure 4 for figure 1 A schematic diagram of the three-dimensional structure of the right processing components and fixtures in the drilling and tapping machine shown; Figure 5 for figure 1 A schematic diagram of the three-dimensional structure of the vertical processing components in the drilling and tapping machine shown; Figure 6 for Figure 5 A schematic diagram of a three-dimensional structure of the vertical processing assembly shown when viewed from another angle; Figu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap