Detachable tail drum for ships and ship installation method thereof

A detachable tail and installation method technology, which is applied to ships and other directions, can solve the problems of increasing the difficulty of maintenance or replacing the tail drum, the process is complicated, and it is inconvenient to use. friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

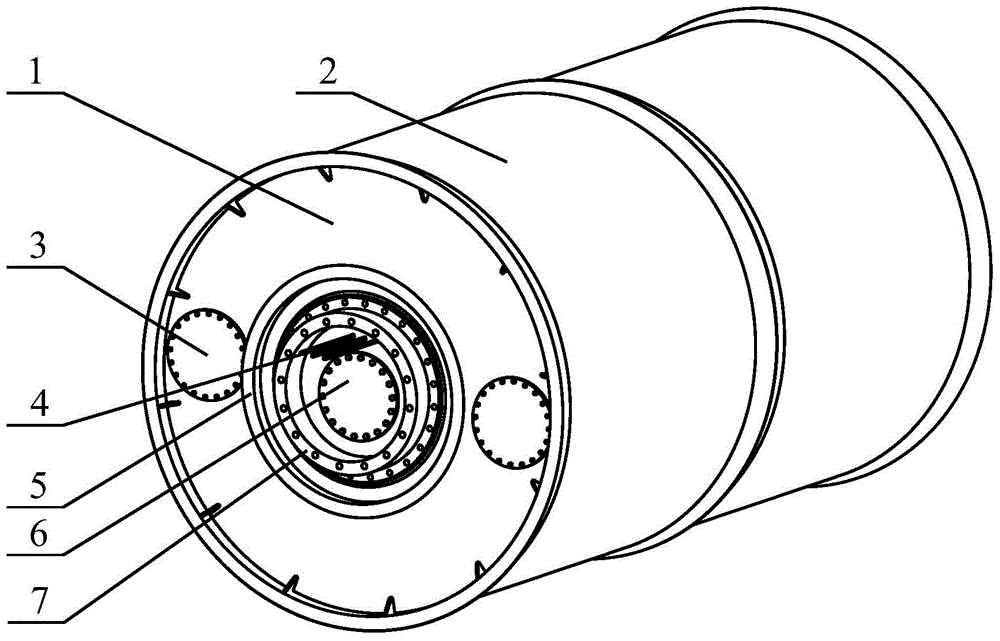

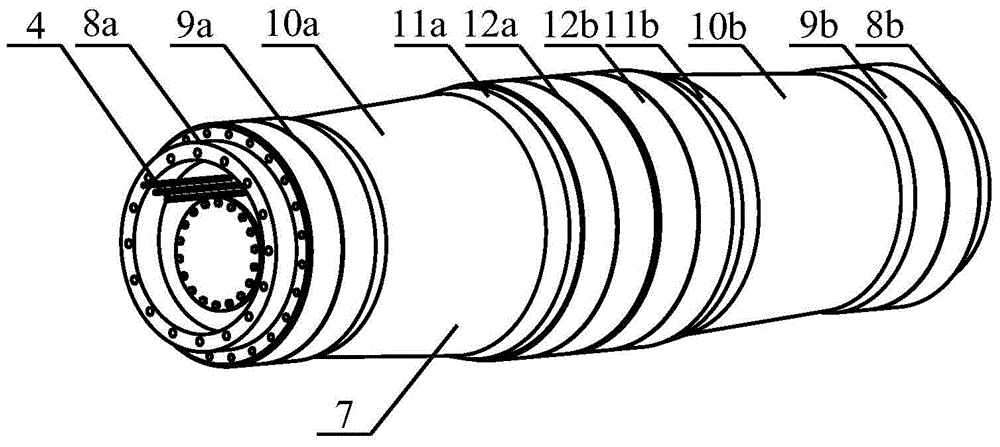

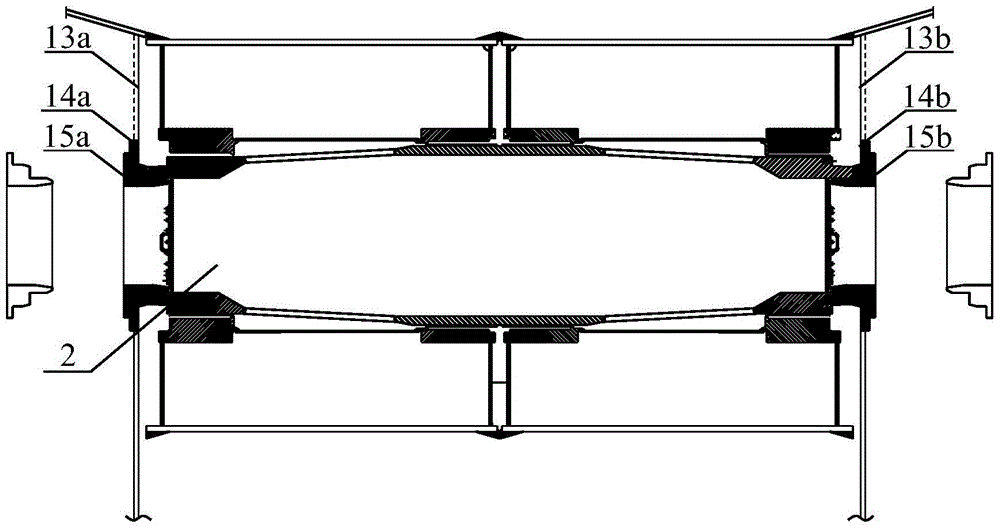

[0033] see figure 1 As shown, the detachable tail drum for ships in the embodiment of the present invention includes a double drum 2 of hollow structure, which includes a left cylinder end sealing plate 1, a right cylinder end sealing plate, and a left rotating bearing 5 and right turn bearing. The left cylinder end sealing plate 1 and the right cylinder end sealing plate are respectively located on both sides of the double drum 2, and the left rotating bearing 5 is located inside the double drum 2 corresponding to the left cylinder end sealing plate 1, turning right The dynamic bearing is located inside the double drum 2 and corresponds to the end sealing plate of the right cylinder; the sealing plate 1 at the end of the left cylinder has at least one inspection hole 3 for the cylinder. In this embodiment, the sealing plate 1 at the end of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap